Diaper Material White Hydrophilic Spunbond PP Non-woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

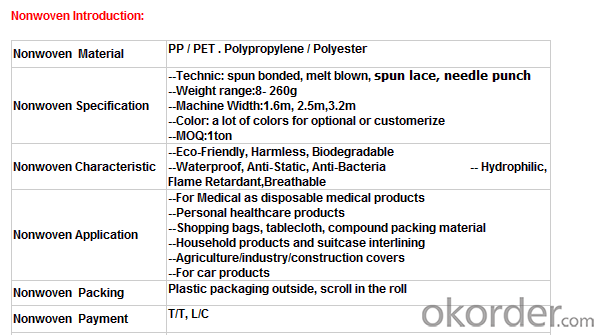

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Application of Biological Enzyme in Textile Processing

- The application of new enzymes in textile processing: the position of chemical synthetic fibers and slurries in the textile is obvious, these polymer can not be biodegradable and degraded, causing environmental pollution, the current researchers are studying the new enzyme

- Q: Textile industry after finishing what pollution, especially air pollution

- At least chronic poisoning for humans and animals is usually the government in order to create achievements or to meet the personal interests of individual officials will be so because of chronic poisoning, after all, there are three or five years or even 30 years of concealment proposed to the Provincial Environmental Protection Office to call complaints or petition

- Q: What are the test tests for the color fastness of textiles?

- 13, resistant to non-chlorine color fastness 14, resistance to chlorine color fastness 15, acid color fastness 16, alkali color fastness 17, water-resistant color fastness 18, resistance to organic solvent friction color fastness

- Q: Lin is what kind of textile

- 4, the common textile fiber textile properties: ① wool: moisture, elasticity, performance are good, intolerant insects, acid and metal combined with dyes. ② silk: moisture, breathable, shiny and good performance, suitable for acidic and direct dyes

- Q: What is the anti-perspiration finishing of textiles?

- At present, the domestic can do single-parent single-finishing manufacturers have a lot, but do not much anti-perspiration finishing manufacturers, because of its high technical requirements, many manufacturers put anti-perspiration requirements made of single-parent single fabric, from In a sense is to complete the customer's request,

- Q: Textile machine, I should use single-phase power or three-phase electricity

- As long as the power of the same, three-phase power and single-phase power production capacity is the same. What is the key to your connector (input) Three-phase electrical industrial electricity, the voltage is more stable

- Q: What is a textile fabric?

- But also to distinguish a few concepts: people cotton fabric: that is not dyeing or other finishing or processing of the loom down the cloth. The premise is that people cotton, so of course pure glue rather than blended.

- Q: Clothing and processing and processing into what auxiliaries

- Textile processing used a lot of additives, spinning from the spinning machine will be used, and then to the weaving, weaving need to sizing the sizing, sizing will also use a variety of additives to increase serous duct toughness

- Q: What is the earliest textile raw material?

- China as early as the Neolithic Age has mastered the textile technology, ancient Chinese silk spinning textile technology, has reached a very high level, renowned in the world

- Q: What is the imo standard in the textile industry?

- The purpose of the Global Organic Textiles Standard is to ensure that textile fabrics and garments of textiles manufacturers are certified and recognized in all major world markets as an important step towards harmonization and transparency of textile marks.

Send your message to us

Diaper Material White Hydrophilic Spunbond PP Non-woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches