non woven fabric with self adhesive /adhesive backed fabric/felt sticker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

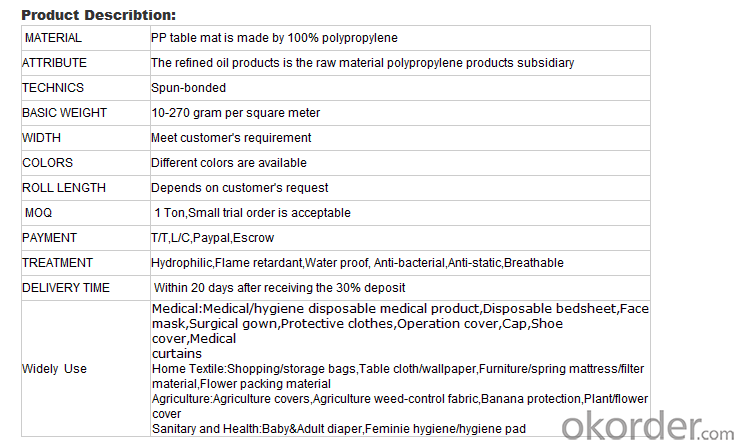

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: How to reduce the cost of textile yarn dyeing

- To sum up, you said that for a little processing fees to save the cost, I think it is not a good way for a business, because you can not save much, in the country to eliminate backward production capacity under the premise of your wisdom more and more narrow; Products to find a way to do different things, do not and the general dyeing factory on the line of homogeneous competition, to make their own company's characteristics!

- Q: What is the meaning of TOP in the textile industry?

- Double-sided cloth can be added in the stereotypes when the anti-water treatment, padding-related anti-watering auxiliaries and then re-type

- Q: What is the anti-perspiration finishing of textiles?

- Many manufacturers put the anti-perspiration requirements made single-parent single defense fabric, in a sense is to complete the customer's request, but the requirements of high customers, only single-parent single effect is unable to meet the requirements, be sure to do Perspiration requirements.Hope to help you, if you want to do further understanding, see my account name and contact me

- Q: What is the difference between the nonwovens industry and the textile industry?

- Textiles are raw materials of cotton, or man-made fibers. Is made of textile machinery, no glue composition. For clothing, bedding and other uses with the human body.

- Q: Textile finishing TPU, TPEF film. What's the difference?

- Hardness range: by changing the TPU reaction components of the ratio, you can get different hardness of the product, and with the increase in hardness, the product still maintain good flexibility and wear resistance.

- Q: Textile and garment industry, including a complete industrial chain which

- The first human clothes are made of animal skins, wrapped in the body of the earliest "fabric" with linen fiber and grass made.

- Q: What is eco textile?

- From the perspective of production ecology, control, including from the fiber cultivation, breeding, production to the whole process of product processing on the environment pollution, the product itself is not "pollution"

- Q: Application of Biological Enzyme in Textile Processing

- Extremely affecting the spinnability of the fiber, hemicellulase and ligninase can be used to remove hemicellulose and lignin, but hemicellulase and ligninase are not used alone in the textile process, mainly And other enzyme preparations (if the gelase, cellulase, etc.) with the fiber treatment

- Q: Classification of cotton textiles

- Decorative textiles in the variety structure, weave pattern and color, and other aspects than other textiles to have a prominent feature, it can be said to be a craft art. Can be divided into indoor supplies, bedding and outdoor products, including home cloth and restaurant bath room supplies

- Q: Why can the oil industry be used as raw materials for the textile industry?

- Commonly used textile industry raw materials are: polyester: polystyrene dicarboxylate; nylon: polyamide fiber; polypropylene: acrylic fiber; acrylic: polyacrylonitrile fiber; polyvinyl chloride: polyvinyl chloride; vinylon: polyvinyl alcohol shrink Aldehyde fiber; aramid: poly (p-phenylene terephthalamide).

Send your message to us

non woven fabric with self adhesive /adhesive backed fabric/felt sticker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords