Non-oriented silicon steel coils with good quality and competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications:

. Thickness:0.35-0.5mm

.Width:1200-1250mm

.50W600, 50W800, 50W1300 or others

2. Description

Products Name | Cold Rolled Non-Oriented Silicon Steel coil |

Material | 50W600, 50W800, 50W1300 |

Standard | GB/T 2521-2008 or as customized |

Size | Width:1200mm~1250mm |

Thickness:0.35-0.5mm | |

Coil weight | 5~8tons |

Coil diameter | 508mm |

Technique | cold rolled |

Surface Treatment | T4 coating |

Workflow | Hot rolled coilàpicklingàrollingàcoatingàdecarburizing annealingàstriping |

Package | Standard seaworthy export packing, or as required |

Loading | Per container can be loaded 25 tons |

Port of shipment | China port |

Payment | T/T or 100% Irrevocable L/C at sight, 30% deposit need to prepaid in advanced |

Delivery time | 10days after receiving your deposit of T/Tor L/C. |

Application | power motor, household appliances, transformers, rectifiers, voltage regulator, electric welding machine, transformers and other electrical and mechanical and small home appliance industry. |

3. Application

power motor, household appliances, transformers, rectifiers, voltage regulator, electric welding machine, transformers and other electrical and mechanical and small home appliance industry.

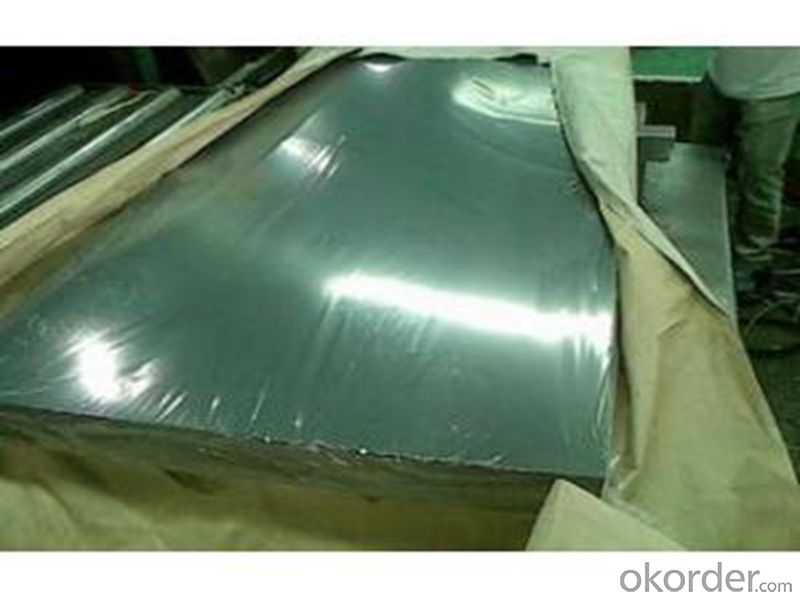

4. Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;

- Q: What are the different types of steel products used in the manufacturing of jewelry and accessories?

- There are several types of steel products commonly used in the manufacturing of jewelry and accessories. These include stainless steel, surgical steel, and carbon steel. Stainless steel is a popular choice due to its durability, corrosion resistance, and affordability. Surgical steel, often used in body jewelry, is hypoallergenic and resistant to tarnish. Carbon steel, though less common, is sometimes used for its strength and unique aesthetic appeal.

- Q: What are the different types of steel wire and their uses?

- There are several different types of steel wire, each with its own unique properties and uses. Some common types include carbon steel wire, stainless steel wire, galvanized steel wire, and high-tensile steel wire. Carbon steel wire is the most widely used type and is known for its strength, durability, and affordability. It is commonly used in construction, fencing, automotive applications, and general-purpose wire products. Stainless steel wire is highly resistant to corrosion and has excellent strength and ductility. It is commonly used in industries such as aerospace, automotive, marine, and medical, where resistance to rust and high temperatures is crucial. Galvanized steel wire is coated with a layer of zinc to protect it from corrosion. This type of wire is commonly used in outdoor applications such as fencing, electrical wiring, and agriculture. High-tensile steel wire is extremely strong and is used in applications that require high strength and durability, such as in the construction of bridges, cranes, and suspension cables. Overall, the different types of steel wire cater to a wide range of industries and applications, providing strength, durability, corrosion resistance, and other specific properties as needed.

- Q: How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is commonly used in the manufacturing of automobile exhaust systems due to its durability, heat resistance, and ability to withstand high temperatures. It is used to create the exhaust pipes, which transport the exhaust gases from the engine to the rear of the vehicle. Additionally, steel tubing is also utilized for the construction of various components within the exhaust system, such as mufflers and catalytic converters, to ensure proper functioning and longevity of the system.

- Q: How is steel used in the manufacturing of mining equipment?

- Steel is used extensively in the manufacturing of mining equipment due to its exceptional strength, durability, and resistance to wear and tear. It is used to construct various components such as drill bits, crushers, conveyor belts, and ore processing machinery, ensuring the equipment can withstand the harsh conditions and heavy loads encountered during mining operations.

- Q: How is steel used in the production of electrical transformers?

- Steel is used in the production of electrical transformers to provide structural support and magnetic properties necessary for efficient power transmission. It forms the core of the transformer, allowing the magnetic field to be created and transferred to the secondary winding, enabling the transformation of electrical energy.

- Q: How is steel sheet metal stamped for automotive parts?

- Steel sheet metal is stamped for automotive parts through a process called sheet metal stamping. This involves using specialized machines and tooling to cut, bend, and shape the steel into the desired automotive component. The process typically includes steps such as blanking, piercing, forming, and trimming to achieve the required shape and dimensions.

- Q: What are the properties of tool steel for precision cutting tools?

- Tool steel for precision cutting tools typically has several important properties: 1. Hardness: Tool steels used for precision cutting tools are known for their high hardness. This allows the tools to retain their sharp cutting edges, even when subjected to high temperatures and repeated use. 2. Wear resistance: Precision cutting tools are often subjected to abrasive materials and high-speed cutting operations. Tool steels with good wear resistance properties can withstand these conditions and maintain their cutting performance over extended periods. 3. Toughness: While hardness is crucial, tool steels for precision cutting tools also need to have a certain level of toughness. This allows the tools to withstand impacts, shocks, and vibrations without chipping or breaking. 4. Heat resistance: Precision cutting tools can generate significant heat during cutting operations. Tool steels with good heat resistance properties can withstand these high temperatures without losing their hardness or temper. 5. Corrosion resistance: Precision cutting tools may be exposed to various corrosive environments, such as oils, coolants, or moisture. Tool steels with good corrosion resistance properties can prevent rusting and maintain their cutting performance. Overall, tool steels for precision cutting tools need to strike a balance between hardness, wear resistance, toughness, heat resistance, and corrosion resistance to ensure optimal cutting performance and longevity.

- Q: What are the uses of steel in the construction of museums and art galleries?

- Steel is widely used in the construction of museums and art galleries due to its strength, durability, and versatility. It is used for structural purposes, including the frames and supports, allowing for large open spaces and flexible layouts. Steel also provides a secure framework for the installation of artworks and exhibits, ensuring their stability and protection. Additionally, steel is often used for the construction of roofs and facades, providing aesthetic appeal and allowing for the incorporation of large windows and natural light, which are vital for the display of artworks. Overall, steel plays a crucial role in creating functional and visually appealing spaces for museums and art galleries.

- Q: How are steel gratings used in industrial flooring?

- Steel gratings are used in industrial flooring to provide a strong and durable surface that can withstand heavy loads, prevent slipping, and allow for the drainage of liquids and debris. They are commonly used in factories, warehouses, and outdoor areas where a robust flooring solution is required.

- Q: What are the different types of steel roofing systems?

- There are several types of steel roofing systems, including standing seam, corrugated, and metal shingle roofs.

Send your message to us

Non-oriented silicon steel coils with good quality and competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords