No Oil Seal Servo motor HG-MR73B Mitsubishi For Computer Embroidery Machine

- Loading Port:

- Hong Kong

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 1200 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Brand: Mitsubishi

Name: low inertia small capacity servo motor

Model: hg-mr73b

Servo motor series: low inertia, small capacity.

Rated output: 0.75KW.

Rated speed: 3000r / min.

Electromagnetic braking: attached.

Power supply: 200V.

The rated speed is 3000r / min and the large speed is 6000r / min.

The high torque is 350% of the rated torque, realizing high torque in the field

of high rotation. It only supports hg-kr series products.

Built in position encoder with high resolution.

Provide standard high-resolution position encoder (4194304p / rev (22bit)).

Realize more positioning function.

To improve the environmental resistance, hg-kr, hg-mr, hg-rr and hg-ur series

products adopt IP65.

Other performance descriptions of Mitsubishi hg-mr73b:

Type: hf-sn servo motor, medium inertia, medium power.

Rated output power: 2.0kw.

Rated speed: 2000r / min.

Electromagnetic braking: Yes.

Oil seal: Yes.

Encoder resolution: 131072p / R Mitsubishi hg-mr73b.

S100 represents mr-e super special motor.

Kh003 is mr-e super special mark.

It is easy to operate and reduce the working load hg-mr73b

Enhanced system cost performance.

, positioning (servo motor encoder resolution: 131072).

High responsiveness.

Vibration control function through adaptive vibration.

Optimized tuning can be achieved by using personal computer and servo setting

software.

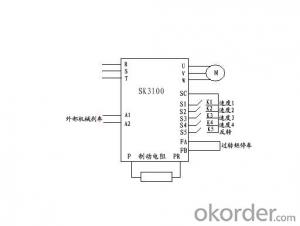

There are 2 types of interfaces:

Pulse train interface is used for position control and internal speed control

of Mitsubishi hg-mr73b.

The analog input interface is used for speed control and torque control.

Widely used.

Feed of processing equipment and machine tools.

For food, packaging equipment and feeding devices.

Used in textile machinery, etc.

It can improve the performance of the equipment.

The terminal strip of servo amplifier adopts connector to reduce the required

wiring time.

The connector is located in front of the servo amplifier to facilitate cable

connection.

The gain of Mitsubishi hg-mr73b can be adjusted conveniently through the real-

time automatic tuning function. Motor series: medium inertia, medium power.

Rated output power: 5.0kw.

Rated speed: 2000r / min.

With or without brake: attached.

Shaft end: keyway (slotted position).

Protection level: IP65 (IP67).

Features: there are three modes of medium inertia from low speed to high speed,

which are suitable for different application ranges.

Application examples: transmission machinery, robot, X-Y worktable.

High resolution encoder 131072p / rev (17 bit) Mitsubishi low inertia small

capacity servo motor.

High resolution encoder is included to ensure excellent performance and

stability at low speed.

All motors are the same size as the previous products and the wiring is

compatible.

Servo motor series: low inertia, medium capacity.

Rated output: 5.0kw.

Rated speed: 3000r / min.

Electromagnetic braking: attached.

Power supply: 200V.

It is suitable for Mitsubishi low inertia small capacity servo motors such as

high frequency operation of medium capacity and low inertia products.

To improve the environmental resistance, hg-kr, hg-mr, hg-rr and hg-ur series

products adopt IP65.

In 100 sites, there are 100 different drive controls.

In order to meet diversified and detailed site needs as much as possible,

In the configuration of mr-j4 product line, it provides abundant servo

amplifiers and servo motor products, Mitsubishi low inertia and small capacity

servo motor.

It can meet the different needs of different customers. Servo motor series:

medium inertia, small capacity.

Rated output: 1.2kW.

Rated speed: 1000r / min.

Electromagnetic braking: without.

Power supply: 200V.

Realize the stable driving of medium capacity and medium inertia products hg-

mr73b.

Through the optimized structural design, the small total length in the industry

is realized.

High speed & high torque Mitsubishi hg-mr73b. Shorten positioning time and

realize high-speed equipment.

Reduce power on torque ripple.

By optimizing the combination of motor poles and slots, the power on torque

ripple is greatly reduced,

Further realize the smooth and constant speed operation of the equipment.

To improve the environmental resistance, hg-sr and hg-jr series products adopt

IP67.

- Q: Equipment Used in the house.Room in the house___________Equipmenta. bathroomb. kitchenc. living roomd. bedroomgive the Equipment of room in the house

- You too eh? I've had to get 2 new tvs, a new computer, had my xbox 360 fixed twice, 2 new mp3 players, a new dvd player and a new alarm clock in the last 8 months. The electronics fairy has curseth me.

- Q: Could this be potentially Electrokinesis?I am prone to having a LOT of static shocks. My computer freezes on me, my TV turns over by itself, my computer, Ipod, Phone turn off by themselves. My phone rings random people, if I put my finger about a centimeter over my touch screen on my Ipod it still works, the internet keeps disconnecting for meyou get the idea. Why does this happen? could it be out of control electrokinesis?

- It's just a bad day for you

- Q: I received 63J at meps and it is a chemical equipment repair job can someone give me the details on this job and what i would do if mobilized. thank you.

- Quartermaster and Chemical Equipment Repairer (63J) The Quartermaster and Chemical Equipment Repairer performs unit and direct/general support maintenance on tactical utility, precise power generation, laundry and bath equipment, pumps, engines, burners, filter units, smoke generation and water purification or associated items. The Quartermaster and Chemical Equipment Repairer is primarily responsible for supervising or performing maintenance on chemical equipment, quartermaster machinery, forced air-heaters and special purpose equipment. Some of your duties as a Quartermaster and Chemical Equipment Repairer may include: Maintaining and repairing electrical/fuel heater systems, pumps, decontamination systems, protective filter systems, smoke generator systems and quartermaster and chemical equipment electrical systems Job training for a Quartermaster and Chemical Equipment Repairer consists of nine weeks of Basic Training, where you'll learn basic Soldiering skills, and 11 weeks of Advanced Individual Training, including practice in marine engine maintenance and repair. Part of this time is spent in the classroom and part in the field. You'll learn: Internal combustion engine theory Use and care of hand and power tools Helpful attributes include: An interest in shop mechanics An interest in fixing engines and machinery An ability to use hand and power tools A preference for doing physical work Advanced level Quartermaster and Chemical Equipment Repairers supervise and train other Soldiers within the same discipline. The skills you learn as a Quartermaster and Chemical Equipment Repairer will help prepare you for a civilian career with the marine transportation, commercial fishing, oil exploration or oil drilling industries. You'll be able to consider a future as a marine engine mechanic.

- Q: I am 57 years old. MBA graduate with substantial experience in Electrical equipment maintenance. I have also experience in NDT.

- No one wants to pay you what you are worth.

- Q: every electrical equipment is rated in VA or KW(motor) why transmission line rated in Volts though it carry power.

- Transmission lines are rated in MVA. They do have a current carrying capacity and limits. However the voltage of these lines is so high and the current so relatively low, that it is the voltage which predominates in determining the heights, clearances, spacings and visual impact of the lines and therefore ultimately also the cost. In consequence common usage very often refers to the rating in terms of voltage only.

- Q: I was wondering, if everyone on earth was to disappear and there was no one to work the electrical grid, how long would it take for 1] The electrical power lines themselves to decay?2] The electrical substations to break down?3] The transformer units to break down?4] Any other electrical equipment to break [such as those boxes on the power lines, as well as ANY other piece of equipment on the electric grid]?P.S- Don't give how long it would take for the power stations to stop running, I already know that. Just answer the four questions I asked.

- The lines are mostly copper or aluminum for the wires themselves. The towers are steel. They would last for decades easily. But lines that run from transformers to homes or neighborhoods could fail earlier. Look at what happens with ice storms in New England. Substations and transformers would last quite long also. But the power stations would last for anywhere from hours to weeks, depending on the degree of automation, and on chance. .

- Q: (hairdressing)

- Anything you'd like to use. Conditioner isn't exactly dangerous.

- Q: a. nuderwriters laboratories b. national fire protection association c. national eletrical contractors association d. institute of electrical and electronics engineers

- A. underwriters laboratories

- Q: I mean for SF6 (gas) containers used to refill electrical quipment such as circuit breakers, must the container be discharged completely, or is it possible to retain a partial amount of SF6 gas in the container for future refilling activities? Any electrical experts out there, would really appreciate your assistance with this. Thanks!

- Check the MSDS sheet for safe transport. Is a seal broken before use? Do the containers get returned after use or are they discarded (how?). Your local power company must have info because they use this stuff at switching stations.

- Q: I am a freshman of the engineering program at the university of Wyoming. Right now I am going into electrical because I wanted to stay in Wyoming and I thought that it would be easier to get a job in the production and distribution of electricity through something like Rocky Mountain Power. I don't mind doing the math and physics for electrical, but I am thinking that I would enjoy becoming a mechanical engineer. At the moment I believe mechanical is much more hands on, designing parts and testing them. I don't know what these two would lead into though. Electrical makes more money, but is that worth it? Also how hard would it be to get a job in this region with mechanical?

- both electrical and mechnical are good field.

Send your message to us

No Oil Seal Servo motor HG-MR73B Mitsubishi For Computer Embroidery Machine

- Loading Port:

- Hong Kong

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 1200 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches