New Products-Auto-climbing Protection Panel1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

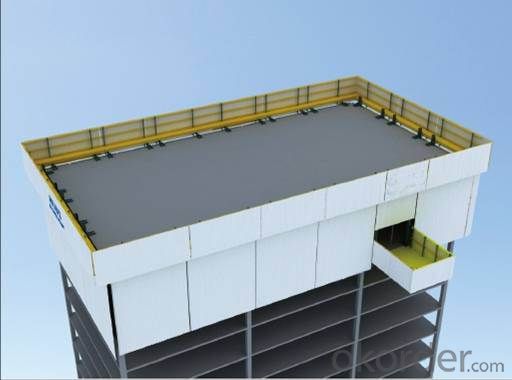

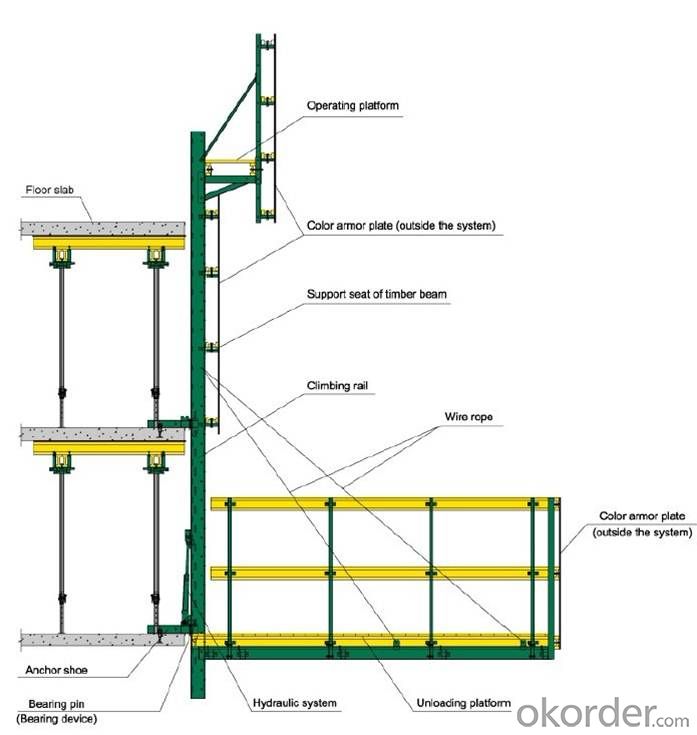

The climbing protection panel isenclosure for construction of

high-rise buildings.The system has hydraulic system as its

power, so it can climb up byitself. Cranes are not needed

during the climbing. Thesystem can match loading platform, 、

which is convenient for movingformwork and other materials

to upper floor withoutdisassembly.The construction efficiency

will be increased highly. Theclimbing protection panel is an

advanced, modern system whichsuits the demand of safety

and civilization, widely used inconstruction.

- Q: How does a steel prop work?

- A steel prop, also known as a steel shore or steel propeller, works by providing temporary support or bracing to structures during construction or renovation. It consists of a steel tube with an adjustable length that can be extended or retracted as needed. By placing the steel prop vertically between the ground and the structure, it helps distribute the weight and load-bearing capacity, preventing the structure from collapsing or sagging. The adjustable feature allows for easy customization to fit different heights and provides stability during construction, ensuring safety for workers and the overall integrity of the structure.

- Q: Can steel props be used in temporary support of walls?

- Yes, steel props can be used in the temporary support of walls. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to provide temporary support to walls, ceilings, and other structures during renovation or construction work. They are designed to be adjustable in height and can be easily installed and removed. Steel props are made of strong and durable steel, making them capable of withstanding heavy loads. They provide stability and support to walls, ensuring that they remain upright and secure during construction or repairs. Overall, steel props are an effective and reliable solution for temporary wall support in construction projects.

- Q: What are the different connection methods available for steel props?

- Steel props can be connected in various ways, depending on the specific needs and uses. Some commonly utilized connection methods are: 1. Pin or Bolt Connection: Steel props are linked together using pins or bolts, allowing for easy length adjustment and providing stability and strength. This method is often employed in temporary structures or scaffolding systems. 2. Welding Connection: Connecting steel props through welding involves melting and fusing the metal at the connection points. This creates a permanent junction that offers high strength and rigidity, making it suitable for long-term or permanent structures. 3. Sleeve Connection: A sleeve connection entails slipping a steel sleeve over the ends of the props and securing it with bolts or pins. This method provides a secure and adjustable connection, facilitating easy length adjustment. 4. Adjustable Coupling Connection: This connection method involves using threaded adjustable couplings on the ends of the props. By tightening or loosening the couplings, the props' length can be adjusted as required. It is commonly used in construction projects that require frequent adjustments. 5. Hydraulic Connection: Hydraulic connections utilize hydraulic cylinders or jacks to connect and adjust the props' length. This method offers precise control over the adjustment and is commonly used in heavy-duty applications or situations that demand a high load capacity. In conclusion, the choice of connection method for steel props depends on factors such as the specific application, load requirements, adjustability needs, and desired strength and stability of the structure. It is crucial to select the appropriate connection method to ensure the safety and efficiency of the construction project.

- Q: Can steel props be used for temporary or permanent support?

- Steel props can be used for both temporary and permanent support, depending on the specific project requirements. Steel props are commonly used in construction and civil engineering projects to provide temporary support during construction or renovation work. They are designed to be adjustable in height, allowing for flexibility in supporting different loads and structures. In temporary applications, steel props are typically used to support formwork, scaffolding, or shoring systems. They offer a reliable and safe solution for supporting structures during construction, ensuring stability and preventing collapse. Once the construction work is completed, the steel props can be easily removed and reused in other projects. However, steel props can also be used for permanent support in some cases. In situations where a structure requires ongoing support or reinforcement, steel props can be installed as a permanent solution. This might be necessary for buildings with weak foundations, structures that have undergone structural modifications, or structures that are at risk of settlement or subsidence. Permanent steel props are usually installed in a carefully engineered manner, considering factors such as load-bearing capacity, structural integrity, and long-term stability. They may be designed as part of a comprehensive structural support system, combining different elements such as steel beams, columns, and braces to ensure the overall stability of the structure. It is important to note that the decision to use steel props for temporary or permanent support depends on various factors, including the specific project requirements, load-bearing calculations, and structural engineering considerations. Consulting with a professional engineer or structural expert is crucial to determine the most suitable solution for each situation.

- Q: Can steel props be used in supporting heavy machinery during installation?

- Yes, steel props can be used in supporting heavy machinery during installation. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in construction and engineering industries to provide temporary support and stability. They are designed to withstand heavy loads and can be adjusted to the required height. When installing heavy machinery, it is crucial to ensure proper support to prevent any accidents or damage. Steel props offer a reliable solution as they are made from high-quality steel, providing strength and durability. They can bear significant weight and distribute it evenly to provide a stable base for the machinery. Additionally, steel props are adjustable, allowing for precise height adjustments as per the machinery's requirements. This adjustability makes it easier to align the machinery and ensure proper installation. However, it is important to consider the specific requirements and specifications of the machinery before using steel props. The weight, dimensions, and center of gravity of the machinery should be thoroughly assessed to determine the number and positioning of the props required. Additionally, it is recommended to consult with a structural engineer or an expert in heavy machinery installation to ensure the safety and effectiveness of using steel props in this specific application. Overall, steel props can be a suitable choice for supporting heavy machinery during installation due to their strength, adjustability, and stability.

- Q: Can steel props be used in supporting precast concrete elements during installation?

- Steel props, also referred to as adjustable steel props or adjustable steel shores, can be utilized to provide support to precast concrete elements while they are being installed. In the realm of construction, steel props are commonly employed as a temporary support system for structures or elements. They are specifically beneficial in the context of precast concrete elements due to their durability, ability to be adjusted, and stability. When installing precast concrete elements, steel props are typically positioned beneath the elements to offer vertical support and prevent any sagging or collapse. The height of the props can be easily modified to accommodate different elevations or to ensure a level installation. This adjustability is particularly advantageous when dealing with uneven ground conditions or when aligning multiple precast elements. Steel props are engineered to endure substantial loads and provide a dependable support system for precast concrete elements. They are typically fabricated using high-quality steel with a robust construction, enabling them to bear the weight of the elements without any deformation or failure. In addition to their strength and adjustability, steel props provide stability throughout the installation process. They are equipped with base plates or feet that establish a solid foundation, ensuring that the props remain securely in place. This stability is crucial in preventing any unforeseen movement or shifting of the precast elements, which could potentially result in damage or safety hazards. All in all, steel props are a suitable choice for supporting precast concrete elements during installation. Their strength, adjustability, and stability make them a reliable and efficient solution for ensuring a successful and safe installation process.

- Q: Are steel props commonly used in commercial construction projects?

- Yes, steel props are commonly used in commercial construction projects. They are versatile and provide temporary support to structures during construction, making them essential for ensuring safety and stability on site.

- Q: Can steel props be used in confined spaces?

- Confined spaces can benefit from the utilization of steel props. These adjustable and versatile support systems are commonly employed in construction, renovation, and maintenance projects. Their purpose is to offer temporary support for structures, like ceilings, walls, and beams, during construction or repair work. In situations where limited access or restricted working conditions are present, steel props can prove particularly advantageous. Being adjustable by nature, they can be extended or shortened to fit the specific height requirements of the confined space. This allows for precise and controlled support, ensuring the safety and stability of the structure being worked on. Furthermore, steel props are typically constructed from durable and strong materials, such as steel or aluminum, which can bear heavy loads. This quality makes them suitable for confined spaces where additional support or load-bearing capacity may be required. Nevertheless, it is crucial to consider certain factors when employing steel props in confined spaces. These include ensuring accurate placement and alignment, conducting regular inspections for any signs of damage or wear, and adhering to safety guidelines and regulations. It is also essential to have trained personnel who possess experience in working in confined spaces and using steel props. All in all, steel props can be effectively used in confined spaces, providing the necessary support and stability required for construction and maintenance activities while adhering to safety standards.

- Q: Can steel props be used in outdoor construction projects?

- Yes, steel props can be used in outdoor construction projects. Steel props are durable, sturdy, and weather-resistant, making them suitable for supporting structures and providing temporary support in outdoor construction sites.

- Q: Can steel props be used in construction of water tanks?

- Yes, steel props can be used in the construction of water tanks. Steel props provide strong structural support and can withstand the weight and pressure of the water tank. They are commonly used in construction projects to provide temporary or permanent support to ensure stability and safety.

Send your message to us

New Products-Auto-climbing Protection Panel1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches