Plastic Tubes - New PPR Pipes and Fittings for Industrial Application in 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview:

1.It is used in industrial fields,agriculture and irrigation.

2.Beauty appearance.

3.Thermal insulation and energy saving.

4.Easy installation

5.excellent heat resistance and pressure resistance

6.affordable price

Specifications

Standard:DIN8077/8078

Material:R200P from Korea

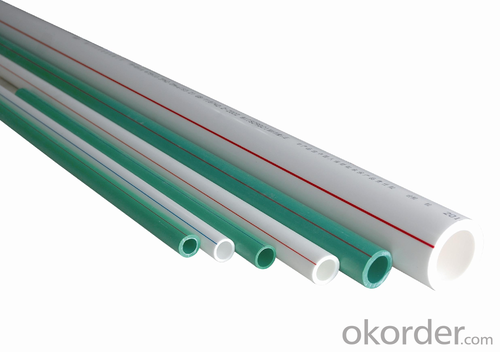

Size:DN20-63

Color:Green,White,Grey,Blue

Packaging Details:PE bag + carton

Delivery Detail:15 Days

Product Description

1.Material: | PPR |

2.Color: | White,Gray,Green,or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1)4-5days-If you want to customize your logo. |

(2)1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1)L/C,T/T,D/P |

Product Show

Our Services

Pre-Sales Service

1.Inquiry and consulting support.

2.Sample testing support.

After-Sales Service

1.Training how to instal the machine,training how to use the machine.

2.Engineers available to service machinery overseas.

FAQ

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union, pay

- Q: Are plastic tubes suitable for medical device manufacturing?

- Yes, plastic tubes are suitable for medical device manufacturing. They are commonly used in various medical applications such as catheters, IV lines, and respiratory tubes due to their flexibility, durability, and compatibility with sterilization processes. Plastic tubes can be customized to meet specific requirements and are cost-effective compared to other materials. Additionally, they offer excellent biocompatibility and can be manufactured to be resistant to chemicals and bacteria, ensuring patient safety.

- Q: Just curious, when there is only a bit of toothpaste left, I have to squeeze little by little from bottom up. But then after using it, I'll have to do the same thing next time around. Obviously the toothpaste has to settle down the tube. Why and how does it do that?

- The plastic material has internal stresses that retain the shape it was cast in originally. Since it is attached to a round head it tends to form a sort of flattened cone. The toothpaste moves back up the tube to fill the available space as it is a type of really thick fluid. The shape may also lead to the toothpaste moving upwards due to capillary action (similar to how water moves up a very thin straw) To combat this effect, you can buy a little squeezy thing that rolls over the tube to prevent the toothpaste from moving backwards, or you can fold/bend it over as you use it like many people do. I store mine upright on the cap so the toothpaste settles at the end I squeeze it out of. The tube also uses less counter space when you store it upright as compared to laid over on its side.

- Q: Can plastic tubes be used for storing art supplies or materials?

- Yes, plastic tubes can be used for storing art supplies or materials. They provide a convenient and protective solution for organizing and transporting items such as paintbrushes, pencils, markers, and even rolled-up canvases. Plastic tubes are durable, lightweight, and often transparent, allowing artists to easily view and access their materials whenever needed.

- Q: What are the advantages of using plastic tubes in the cosmetics industry?

- There are several advantages of using plastic tubes in the cosmetics industry. Firstly, plastic tubes are lightweight and portable, making them convenient for travel and on-the-go use. Secondly, plastic tubes provide excellent product protection, preventing contamination and preserving the quality and shelf life of cosmetics. Additionally, plastic tubes are cost-effective, allowing for affordable packaging options, especially for smaller cosmetic brands. Lastly, plastic tubes are versatile and can be easily customized with various colors, shapes, and sizes, enhancing product aesthetics and branding.

- Q: I already have a plastic water line with a on off switch coming up through the floor. I bought a new fridge and when they delivered it they said they could not install it because of the plastic tube- they said I had to change it- I've been to home depot etc and have no clue how to do it because everything else seems to be for the actual installation of a brand new line whereas in this case I need to know how to change the existing line. Any answers??

- You didn't say why it needs to be changed. If it takes a different size tubing, you will be running a new line. If the nut on the end of the tubing is not the correct one, you may be able to buy and install a new one. You would need to go to the parts section at HD. They have all types of connectors.

- Q: Are plastic tubes resistant to discoloration?

- Yes, plastic tubes are generally resistant to discoloration.

- Q: What are plastic tubes made of?

- Plastic tubes are made of various types of polymers, such as polyethylene, polyvinyl chloride (PVC), or polycarbonate, which are molded into tube shapes to provide strength, flexibility, and durability for different applications.

- Q: Can plastic tubes be used for marine applications?

- Yes, plastic tubes can be used for marine applications. Plastic tubes, such as those made from PVC or polyethylene, are commonly used in various marine applications such as plumbing, irrigation, bilge pumping, and water circulation systems. These tubes are resistant to corrosion, have good durability, and can withstand harsh marine environments, making them suitable for use in boats, ships, and other marine structures.

- Q: Are plastic tubes resistant to weathering?

- Plastic tubes can vary in their resistance to weathering depending on the type of plastic used. Some plastics are more prone to degradation when exposed to sunlight, extreme temperatures, or harsh weather conditions, while others are designed to be more resistant. It is important to consider the specific plastic material and its intended use when determining its level of weathering resistance.

- Q: What is the maximum temperature plastic tubes can withstand?

- The maximum temperature that plastic tubes can withstand varies depending on the type of plastic used. However, in general, most plastic tubes can withstand temperatures up to around 150-200 degrees Celsius. It is important to consult the specific specifications provided by the manufacturer to determine the maximum temperature resistance of a particular plastic tube.

Send your message to us

Plastic Tubes - New PPR Pipes and Fittings for Industrial Application in 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords