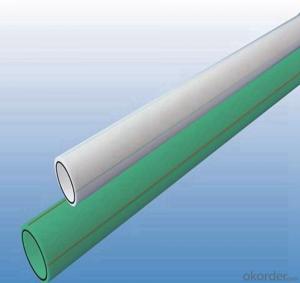

Plastic Tubes for New PPR Pipe Watering Irrigation in Industrial Fields

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Main Product Features

Large drum hub to maximize cable life

Self-activating automatic brake hold the load securely when crank handle is released

With cable or strap

Safety guard cover available

Top quality with competitive price

Widely used in the double beam bridge crane and gantry crane

Easy to install and high quality

Compact structure and reasonable design

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: I am doing a project and i have a plastic tube that need to go in circles so i need to straighten it. Any Ideas? I need this fast please. :)

- Blow dryer on high or a heat gun on low. The heat gun will be the most likely to work. Not knowing your age I will say that you can get your parents to put it in your oven and set the temp for say 170F or less and heat it for 3-6 min. That will soften it up but if your oven does not go that low forget that method. The oven method would be my last choice. Just thought of one. If you have a rice cooker or steamer that may work if it is big enough. The steam will heat it but not burn it. But again if you are a minor have your parents do it. This you will have to watch and again it would not be my first choice.

- Q: How do you dispose of plastic tubes?

- Plastic tubes should be disposed of in a responsible manner by recycling them. If recycling is not available in your area, they can be thrown in the regular trash.

- Q: What is the thermal fuse sleeve of the wire mesh plastic composite pipe?

- Hot melt connection quota of plastic pipe.

- Q: What are the different diameter ranges available for plastic tubes?

- The diameter ranges for plastic tubes can vary widely, ranging from as small as a few millimeters to several inches in diameter. The specific diameter options available depend on the type of plastic used, the intended application, and the manufacturer's capabilities.

- Q: How can I make a frosting tube?You know, the stuff you put frosting in squeeze it out?I want it to come out thin kind of so I can write Welcome homeCan't you like put it in a regular plastic baggy?But how do I make a nozel for it to come out of?...I need one within the next half hour. I Cannot go to the store fir anything..HELP

- Like everyone else has said : Ziplock bag. Put the frosting into the bag, close the bag. Snip off a bottom corner, and squeeze from the opposite corner.

- Q: Can plastic tubes be used for hydroponics?

- Yes, plastic tubes can be used for hydroponics. In fact, they are commonly used as a cost-effective and efficient option for hydroponic systems. Plastic tubes are lightweight, durable, and resistant to corrosion, making them suitable for circulating nutrient-rich water to the plants' roots in a hydroponic setup.

- Q: Are plastic tubes resistant to freezing temperatures?

- Yes, plastic tubes are generally resistant to freezing temperatures.

- Q: PVC flame retardant pipes have three kinds of ABC, heavy duty is not rigid flame retardant tube?

- Pipe length 4m/ root, the color is white, pure white, bending needs special bending spring. Pipe connections using special joint insertion connection, the connection with the special surface coating adhesive, sealing interface.

- Q: What flange plate is used to connect the plastic pipe to the flange valve?

- Plastic pipe and flange valve connection flange, usually only two kinds of material holding, a stainless steel, a non-metallic material. In fact, the gold plastic pipe flange connection can be divided into flange and looper flange.

- Q: I'm building a science project with my little sister, and we quite frankly need some help. The plan is to make a little rollercoaster out of plastic tubing as the track. It's kind of thick, so it doesn't bend very well. We've been straightening it out for a couple days, but it's still slightly wavy. We need to get it into a solid position. The plan is to support it on some boxes, and maybe tape it down so it holds it's form.But, there is a part in the rollercoaster where it needs to be extremely straight. Any ideas??

- Classic Plastic

Send your message to us

Plastic Tubes for New PPR Pipe Watering Irrigation in Industrial Fields

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords