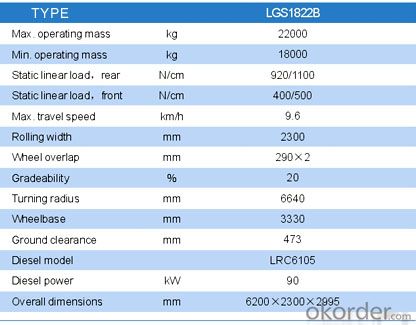

New Design Static Three Wheel Roller manufactured in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Articulated heavy duty three wheel static roller is suitable for compaction of various such as gravel, crushed stone, sand-macadam mixture, sandy soil, stabilized soils and bituminous concrete etc. on base course and surface construction, which is a universal compaction equipment for highway, municipal road parking area and industrial ground.

YITUO LRC6105 diesel engine from technology of Ricardo company U.K. with rich power surplus.

Heavy-duty gearbox and driving axle assure reliability and smoothness of travel transmissions.

Hydraulic power steering system, forward and backward three travel speed gears.

Articulated machine frame with smaller turning radius, flexible maneuverability.

Front and rear drums at large diameter for smooth and effective compaction.

Electric power sprinkler system with reinforced polyethylene water tank(option).

Robust operator's cab with air conditioning system can be equipped as option

Welcome you to visit our factory in China. Anything we can do, please feel free to let us know. We are sure your inquiries will get our prompt attention.

- Q: What kind of vibratory roller is used in roller compacted concrete construction?

- First of all, roller used vibratory roller.Then。 Concrete rolling, according to the thickness of different layers, the use of different performance vibration roller (also known as vibratory roller)Specific should look at the scale of your project to choose, not a single model of the roller will be able to solve.Hope to be of help to you.

- Q: Roller vibration pump solenoid valve is new. Point road no problem. Sometimes there is no vibration. Sometimes not stop, you can always, flameout, restart no longer. Is it the pump problem? Under the guidance of an old master

- Upstairs said is extremely, check control circuit. I add the following points: 1: ask: do you say the solenoid valve for the new? Why is it new? What was the trouble before?. 2: asked: "you say that the circuit is no problem, how to judge?" According to where? I put forward the inspection idea: first, judge the circuit problem: take the solenoid valve coil at both ends, turn on the power, open the Qiang Qiangzhen or weak earthquake. With a screwdriver into the coil inside the hole, if there is magnetic, that the line is through, the size of the shock, try. Instead, the coil is not called. There's something wrong with the line.

- Q: What is the influence distance of the road roller on the building?

- This generally does not affect the house, and if so, leave proof

- Q: The role of rubber tyred roller is used for water steady rolling

- Rubber roller and double steel roller is generally in asphalt concrete pavement use; rubber tire roller plays a role, enhance the degree of fit between aggregate and asphalt concrete, reinforced compactness; double steel roller has the effect of asphalt concrete.

- Q: How heavy is the biggest roller?

- We used the largest roller weight 33 tons, and then there is no reproduction, upgraded version is not clear

- Q: How big is the 20 ton bottle?

- 20 tons of roller storage battery should be 2 12V120A, and I hope to be helpful to you.

- Q: When the asphalt surface is rolled, why should the driving wheel of the roller be geared to the paver?

- The asphalt layer is thin and the drive wheel is not easy to rub before.

- Q: At the construction site, should the scraper, dump truck and roller be equipped with sprinkler?

- Desired... First, it's cheaper.. Or because the construction will cause a lot of dust?.. Use a sprinkler to reduce dust

- Q: What are the specific types of Compactors? What is the function of each? What is the difference?

- Here I will not say too much! Because Chinese electromechanical data network is quite comprehensive! Pure non handwritten copy and paste to forget to hope you can have a more in-depth understanding of!

- Q: What's the difference between a three wheeled steel cylinder roller and two wheeled steel cylinder roller?

- This difference. There is no need to say the difference between them. Because generally, if they are all machines that the road must be equipped with, there are two types of machinesRoad asphalt mixture shall be compacted with the following machinery:Double drum steel roller: 8t;

Send your message to us

New Design Static Three Wheel Roller manufactured in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords