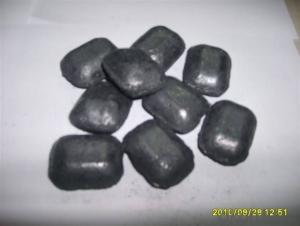

Graphite Powder for Drawing - Natural Amorphous Graphite Powder FC 85%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Metric Tons m.t.

- Supply Capability:

- 100000 Metric Tons per Year m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

- Size: 40-325mesh

- Type: Natural

- Application: foundry, casting, coating material

- Shape: Amorphous Graphite Powder

- Carbon Content: Medium-Carbon

- colour: iron black

Specifications

natural amorphous graphite powderFC85%min

Size40-325mesh

high lubricity,heat-resistance

highly resistant to acid and alkali

Amorphous Graphite Powder

FC:85%min

Moisture: 2.0%max, 2.5%max

Size: 20mesh, 40mesh, 60mesh, 80mesh, 100mesh, 150mesh, 200mesh, 300mesh, 325mesh

Quantity: 100000mt/year

- Q: What are the hazards of inhalation of graphite dust?

- It must be harmful to human beings! Look at the dictionary of carbon black dust lung disease Description: black carbon pneumoconiosis: long-term inhalation of carbon black dust caused by pneumoconiosis. Carbon black is mainly the quality of easy flying carbon. Although the production has been closed and automated, the phenomenon of dust flying still exists. Therefore, workers who produce and use carbon black may have black carbon pneumoconiosis, the shortest length of onset is 15 years, the longest can be more than 25 years, the clinical symptoms are mild, and the progress is slow, and generally does not affect the ability to work.

- Q: Can I use super fine stone powder in grease or lubricating oil?

- Yes, it can play a role in increasing extreme pressure. But it has little effect on low temperature and high temperature resistance. It can not play the role of total synthesis of molybdenum disulfide high temperature grease.

- Q: Which shipping company can pick up the name of graphite? Graphite products are mainly exported to India, Italy and the United states!

- Graphite is neither a liquid nor a dangerous substance. There is no excuse for not answering it.

- Q: How to identify iron powder and graphite powder in a simple way?

- According to the nature of the difference between the two substances: graphite powder has a greasy feeling, iron powder does not;

- Q: Can graphite powder be found in plastic?

- Can effectively improve these shortcomings of plastic, so graphite powder can be used in plastic, and I hope to help you, I hope to adopt, thank you very much.

- Q: Know how the colloidal graphite powder comes in

- Colloidal graphite is a kind of nano material of graphite. The particle size between 1 and 100 nm is called colloidal graphite.Colloidal graphite prices are mainly based on the grain size and carbon content to develop, according to the amount of carbon graphite into high purity, high and medium carbon and low carbon four files, each grade of the difference between the price of a large, but since processed into colloidal graphite, then the carbon content of high carbon should at least be above, if there is no way know the amount of carbon it can only roughly estimate the price of 4-6 million / ton, if it is pure graphite (carbon 99.9%-99.99% above) the price is at least 100 thousand / ton

- Q: What solvent can be used to dissolve Teflon?

- Read a lot of written data, molten alkali metal, high-temperature fluorine material, radioactive radiation, etc., may be dissolved in polytetrafluoroethylene.

- Q: Crystal graphite of graphite powder

- The crystal structure of highly structured pyrolytic graphite, La above 2000Nm, from low temperature to high temperature, the thermal conductivity changes with the temperature is bell shaped, see Figure 1, figure 2.

- Q: What is the ratio of the coated sand to the graphite powder? How to improve the refractoriness of precoated sand

- Or change the sand species, change the high refractoriness sand species, this cost is relatively large.

- Q: What kinds of graphite powder has it? What's the function?

- Its main use focuses on sealing and lubrication, and stone toner is powder, is the basis of other graphite products

We carry out a comprehensive consolidation and integration of amorphous graphite resources, aiming to make graphite industry more stronger, better, bigger, further, and lead a healthy and sustainable development.

In the next 3 years, we will invest 3 billion to build up the fine and deep processing chain of graphite, making the radical improvement in graphite industry .

1. Manufacturer Overview

| Location | Hunan,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Huangpu |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Japanese, Korean |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Graphite Powder for Drawing - Natural Amorphous Graphite Powder FC 85%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Metric Tons m.t.

- Supply Capability:

- 100000 Metric Tons per Year m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches