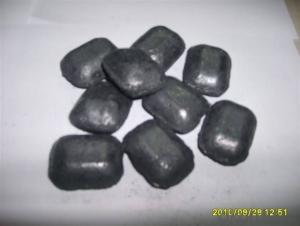

Graphite Oxide Powder - Natural Amorphous Graphite Powder FC 60%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Metric Tons m.t.

- Supply Capability:

- 100000 Metric Tons per Year m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

- Size: 40-325mesh

- Type: Natural

- Application: foundry, casting, coating material

- Shape: Amorphous Graphite Powder

- Carbon Content: Medium-Carbon

- colour: iron black

Specifications

natural amorphous graphite powderFC60%min

Size40-325mesh

high lubricity,heat-resistance

highly resistant to acid and alkali

Natural Amorphous Graphite Powder

FC:60%min

Moisture: 2.0%max, 2.5%max

Size: 20mesh, 40mesh, 60mesh, 80mesh, 100mesh, 150mesh, 200mesh, 300mesh, 325mesh

Quantity: 100000mt/year

- Q: What's the conductivity of graphite powder, silver powder?

- The resistivity of silver is about 1.6*10-8.M at room temperature

- Q: How to measure the conductivity of powdered graphite?

- Voltammetric measurement of resistanceMethods: using precision small range measurement of electricity meter, multimeter resistance or contrast test you can use small bulbs, according to the brightness of his conductivity, if the bulb is more bright, that resistance is lower.

- Q: Does anyone know how to change graphite powder into graphite?! What kind of equipment do you need?!

- Graphite powder, the first thing you should do is broken to a certain number of graphite powder, then add oil glue, is what we often say that the asphalt rubber, but imports of stone glue made less than impurities, suggest you use imported oil glue mixer, stir evenly into the mold machine with hydraulic pressure, hydraulic machine is 3000T this is a general, graphite block grinding pressure type, pressure oil well placed after the glue soak for seven days, and then go to the three or four roasting roasting, can be used, according to your different purposes, different adjustment process.

- Q: Graphite powder screening process, because with static holding together, resulting in vibration screen plugging network how to solve?

- Electrostatic earthing or electrostatic eliminator. In fact, there is a certain conductive graphite powder is very fine, but so long as the electrostatic would slightly have great effect, give you two ways, one is the good grounding conductor can be static vibration sieve, go through a grounding wire guide;

- Q: What graphite powder made of graphite products, high hardness?! Wear-resisting! Good moisture! It can be made into graphite products at 100-200 degrees high temperature

- Graphite powder and resin mixing, molding, and then "high temperature" curing made graphite products, but the intensity of what will not be very high. Usually graphite products are not prepared directly with graphite powder, but with various kinds of coke, such as asphalt coke, petroleum coke, etc. the graphite products prepared by this method have high strength.

- Q: Know how the colloidal graphite powder comes in

- There are two ways to make colloidal graphite: (1) mechanical method. Natural graphite is crushed and treated with hydrochloric acid and hydrofluoric acid to remove impurities. Added to the aqueous solution of tannic acid, which is repeatedly inverted into paste. Colloidal graphite can be obtained by adding a certain proportion of water and ammonia, and then by ultrasonic treatment to further reduce the particle size. (2) chemical method. After being purified and crushed, the natural graphite is added with concentrated nitric acid and concentrated sulfuric acid and water at 90 DEG C, and then obtained by cleaning, drying, adding water, ethanol, acetone and other dispersing agents to obtain colloidal graphite. Add stabilizer such as sodium oleate, sulfate and so on, so that graphite particles do not agglomerate. Ammonia transfers the graphite colloid to the gum solution and regulates the pH value.

- Q: Is the graphite powder poisonous?

- There are three kinds of substances that fly out of the black spot from the carbon factory:1. Bituminous dust.2. A relatively fine particle of calcined coke (petroleum coke after calcination).3. A fine particle of calcined and graphitized Shi Mofen (calcined coke and bituminous mixture).Both poisonous.

- Q: Two simple physical methods are used to identify iron powder and graphite powderHurry up, you need it urgently! Thank you

- That's simple. Just use a magnet. Iron is stronger than graphite. Test the conductivity, or measure the density, because the two substances are black and the color doesn't work. I wish you progress in your studies

- Q: How much is the price of graphite powder for a ton?

- Qingdao Chenyang graphite is China's Graphite brand-name products, strong technical force, perfect measuring and testing, quality assurance system.

- Q: Graphite powder made of graphite oxide, how much weight gain?

- The specific gravity is 1.9 ~ 2.3. Under isolated oxygen conditions, the melting point is above 3000 degrees Celsius and is one of the most refractory minerals. At room temperature, the chemical properties of stone toner are relatively stable, insoluble in water, dilute acid, dilute alkali and organic solvents. The material has high temperature resistance and conductivity, and can be used as refractory materials, conductive materials, wear-resistant and lubricating materials.

We carry out a comprehensive consolidation and integration of amorphous graphite resources, aiming to make graphite industry more stronger, better, bigger, further, and lead a healthy and sustainable development.

In the next 3 years, we will invest 3 billion to build up the fine and deep processing chain of graphite, making the radical improvement in graphite industry .

1. Manufacturer Overview

| Location | Hunan,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Huangpu |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Japanese, Korean |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Graphite Oxide Powder - Natural Amorphous Graphite Powder FC 60%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Metric Tons m.t.

- Supply Capability:

- 100000 Metric Tons per Year m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches