Nashiji Pattern Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Ton/Tons 1*20GP kg

- Supply Capability:

- 300 Ton/Tons per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Model Number: GYYE001

Function: Decorative Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Figured Glass,Tinted Glass

Type: Float Glass

Color: Clear, Bronze, Grey, Blue, Grey,ect

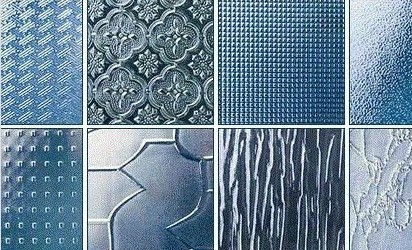

kind of Pattern: Nashji,mistlite,kasumi,water wave,karatachi,...

Size: 1830*2440,1650*2200,2140*1830,2140*3300mm

Thickness: 4-12mm Brand: Guangyao

Grade: AAA

Advantage: Tangible stereoscopic ,never fade

Application: building glass,window glass,decoractive glass,and so on

Certificate: ISO9001,CE

Packaging & Delivery of Pattern Glass

Packaging Details: common export crate package,inner packing with papers interleaved between two sheet of glass.

Delivery Detail: 20days after receive your advance payment.

Specifications of Pattern Glass

Nashiji pattern glass:

1.kinds of color and patterns;

2.high quality & good service;

3.never fade

4.Meet ISO 9001,CE standa

Nashiji pattern glass:

FEATURES:

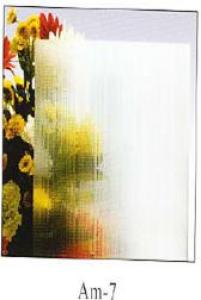

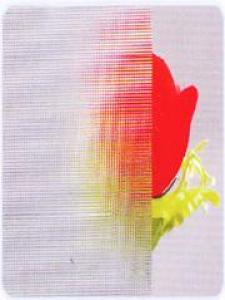

1) Rich and colorful pattern designs provide unique decorative results: or obscure and quiet, or sparkling and lively, or serious and elegant, or bold and generous

2) Tangible stereoscopic patterns will never fade.

3)Patterned glass can be cut, ground, drilled, tempered, laminated and printed, etc.

SPECIFICATION:

Thickness: 3mm-6mm.

Sizes: 1220x1830mm, 1500x2000mm, 1830x2134mm, 1830x2134mm etc

Patterns: Aqualite, Bamboo, Beehive, Chinchilla, Crystal, Diamond, Flora, Karatachi, Masterlite, Mistlite, Nashiji, and Rain etc.

Colors: Clear, Bronze, Grey, Blue, Grey and Amber etc

- Q: Chemical materials and additives needed for the production of glass

- Production process of 1.3.1 glass1. Raw material pretreatment. The bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) grinding, so that dry wet raw materialsDry, iron containing raw materials for iron removal, in order to ensure the quality of glass.2, batch preparation. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..3, melting. The glass mixture is heated in a bath or crucible furnace at a high temperature (1550-1600 degrees) to form a liquid glass that is uniform, free of bubbles and conforms to the molding requirements.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Ceramic crystallization: glass ceramic composite board is the product of "three in one" of glass, ceramic and stone craft. It combines the glass melting process, ceramic brick molding and crystallization sintering process, stone polishing, cutting process as a whole. In short, microcrystalline glass frit is special stalls shop in the special ceramic tile on the roller kiln sintering crystallization, after polishing and cutting timber.

- Q: What is the difference between acrylic board, lotus board, organic board and PVC board?

- Organic boards are called organic plates, PS boards, PS organic boards, PS boards, light panels, light box boards, GPPS boards, benzene boards, color boards, etc. some places are simply called organic glass. People have different opinions. In fact, organic boards are different from organic glass.

- Q: What are the raw materials for low dielectric glass fiber?

- Glass fiber is divided into different grades according to its composition, properties and uses. According to the provisions of the standard level (see table), E glass fiber is most widely used, widely used in electrical insulating materials; special fiber grade S, while the output is small, but very important, because it has super strength, mainly used for military defense, such as bullet proof box; C level more than E with chemical resistance in the battery isolation plate, chemical filter; a basic glass fiber reinforced materials used in the production.The main component of glass fibre and its main components are silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide, depending on the amount of alkali content in glass, can be divided into non alkali glass fiber (Na2O 0% ~ 2%, which belongs to the aluminum borosilicate glass), glass fiber (8% ~ sodium sodium calcium silicate glass 12%, a boron containing or not containing boron) and high alkali glass fiber (Na2O 13%, sodium calcium silicate glass).

- Q: Is glass steel pipe used for re examination?

- The basic construction phase: reinforced approach sampling, sample (drawing on the provisions of the various specifications of reinforced earth excavation (), earthwork excavation scheme, technical tests, foundation trench inspection records, batch inspection, inspection, hidden) cushion (hidden, concrete construction inspection group, line records, line technology review), base (reinforced raw materials, test report review, reinforcement, formwork and concrete construction scheme, technical disclosure, concealment, reinforced bar, inspection lot, line records, technical review, concrete concealed, concrete construction inspection group, and with the standard curing conditions and stripping test block), basic brick (program, technical disclosure, in advance. Mix ratio of mortar, concealment, inspection batch, mortar block), the template removal (removal of specimen report report, concealment, inspection batch), backfill (scheme, technical clarification Concealment, inspection, batch, earthwork density test).

- Q: The main raw material for the impact of float glass cost?

- About the 70% main components of float glass is silica, the main raw material is corresponding to the sandstone or silica sand (sand), the raw material price level will seriously affect the glass manufacturing cost.

- Q: How to identify and select high quality insulating glass?

- At present, there are three kinds of insulating glass in China: (1) groove aluminum type single channel sealing; (two) groove aluminum double channel sealing; (three) compound sealant strip type insulating glass. Groove type aluminum single channel seal, because of its poor sealing, easy to enter moisture, resulting in condensation of glass, frosting, short service life, so the kind of insulating glass gradually eliminated.

- Q: FRP process piping manufacturing process?

- Preparation processA, device debugging. First, carefully check the equipment operation and work site is normal, especially to carefully check the resin curing agent for two-component pump is clogging, the ratio between whether to meet the design requirements; to ensure the lining, winding, trimming, stripping and other equipment operation stability and accuracy;B, cleaning mold. Mold surface without pit, dust, debris and other attachments, the mold should be smooth surface, there is a problem in time to repair and maintenance;C and wrapped polyester film. For the convenience of pipeline release, with 1 layers of polyester film in the mold surface film, lap width of 1 ~ 2 cm, the thickness is between 40um. For the film without damage, no fold, both sides are smooth and clean. The quality of the film meets the requirements of GB 13950-1992.

- Q: Use of glass flake cement

- Good temperature resistance. The use of glass scale lining, its heat resistance than similar resin coating can be increased by 20-40 degrees, so often used in oil pipelines, hot water pipelines, heat resistant chemical devices.

- Q: What are these things that belong to the reactor's raw materials?

- Iron core reactor raw material is similar, more out of the core is made of silicon steel sheet, folder is steel. The lead wires and the wiring bronze are likely to use heat shrinkable sleeves, but this is also available.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2005 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America 2.50 South America 10.00 Eastern Europe 5.00 Southeast Asia 10.00 Africa 2.50 Mid East 5.00 Western Europe10.00 Central America 5.00 Domestic Market 50.00 |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao,Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English, Chinese, Russian, Korean |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Nashiji Pattern Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Ton/Tons 1*20GP kg

- Supply Capability:

- 300 Ton/Tons per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches