N80-P110 Grade Oil Tubing Direct 13Cr Oil L80 Oil Tubing,Superior Quality High Cost-Effectiveness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

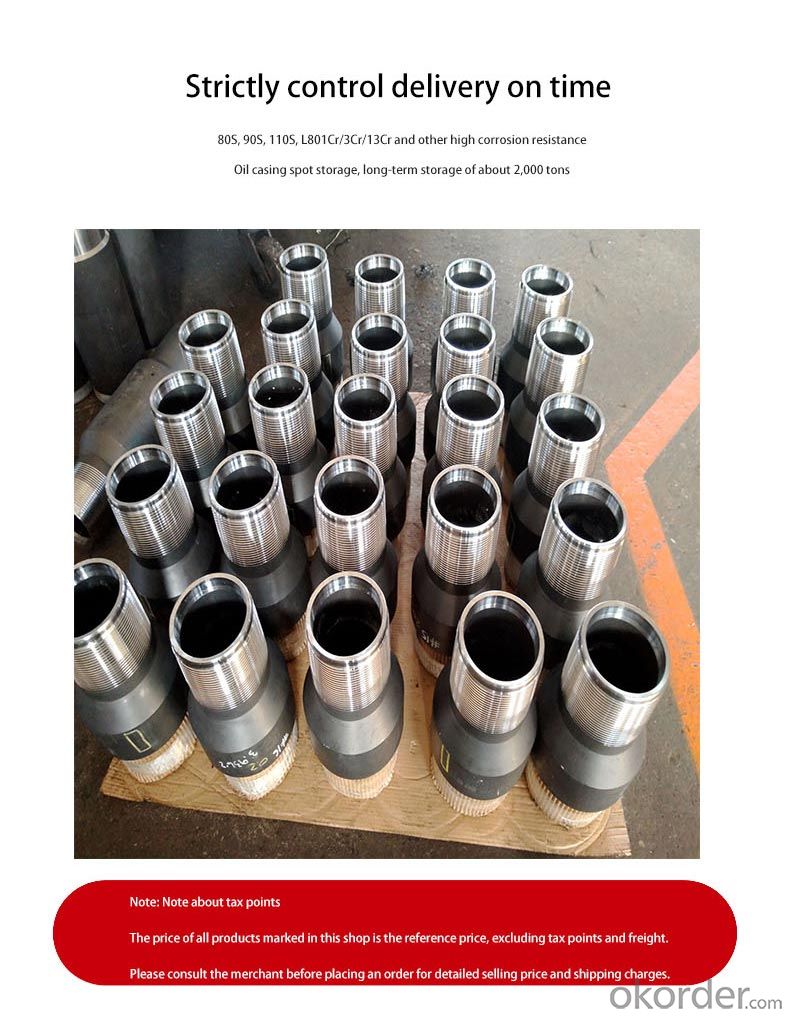

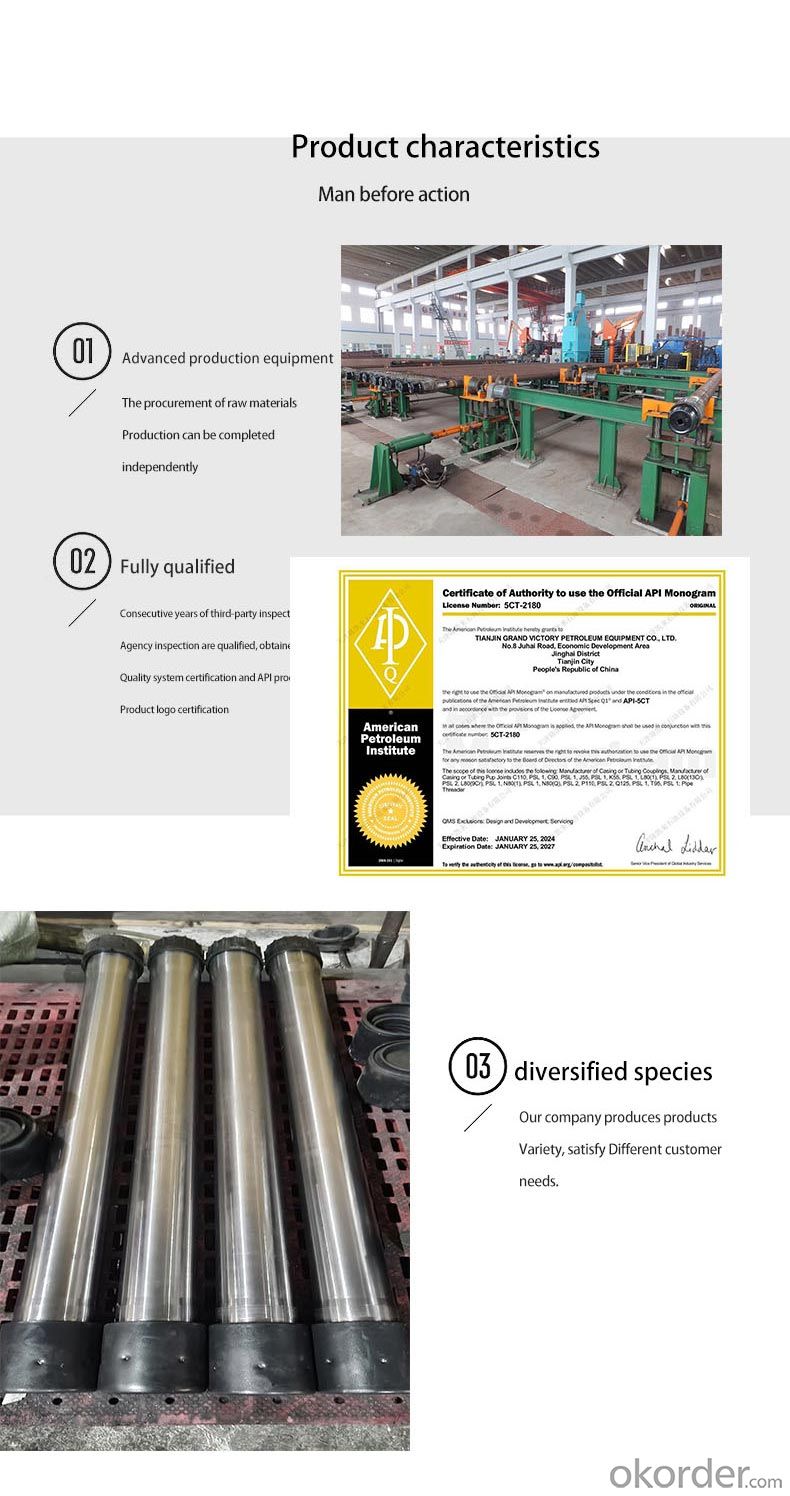

API 5CT J55/N80/P110 OCTG Casing & Tubing Manufacturer Direct

Comprehensive OCTG Solutions for Every Well Profile

As an API-licensed manufacturer, we eliminate intermediaries to deliver J55/N80/P110 casing and tubing with 15% cost savings. Our vertically integrated production process ensures full traceability from steel billet to finished product.

Technical Specifications

Material Science:

J55: 0.45% Mn, 0.25% C composition for shallow wells (≤8,000ft TVD)

N80: Quenched & tempered microstructure withstands 12,000psi collapse pressure

P110: 110ksi SMYS with Charpy V-notch impact ≥45J at -20°C

Threading Technology:

CNC-machined API LTC/BTC threads with ±0.003" pitch diameter tolerance

Optional VAM TOP connections for HPHT wells

Quality Assurance:

100% ultrasonic testing (UT) for laminations

Hydrostatic tested to 80% of yield strength

Applications

J55: Water injection wells, surface casing

N80: Intermediate casing in sour gas fields

P110: Production casing in 15,000psi reservoirs

Case Study

A Permian Basin operator reduced casing costs by 18% using our direct-shipment P110 casing for 35 horizontal wells, achieving 95% torque-turn compliance during running

- Q: How are steel pipes used in the infrastructure development?

- Steel pipes are widely used in infrastructure development for various purposes. They are commonly used for transporting water, oil, and gas, as well as for drainage systems and sewage networks. Steel pipes are also used in the construction of bridges, buildings, and highways, providing structural support and stability. Additionally, steel pipes are utilized in underground utilities, such as telecommunications and electrical systems. Their durability, strength, and resistance to corrosion make steel pipes a crucial component in infrastructure development.

- Q: What is the maximum diameter of steel pipes?

- The maximum diameter of steel pipes can vary depending on the specific needs and requirements of a project. However, steel pipes are commonly available in diameters ranging from 1/8 inch to 72 inches or even larger.

- Q: What is the minimum temperature that steel pipes can handle?

- The minimum temperature that steel pipes can handle depends on the specific grade and composition of the steel. Generally, steel pipes can handle extremely low temperatures without experiencing any significant issues. In fact, many types of steel are specifically designed to withstand extremely cold temperatures, making them suitable for various applications in industries such as oil and gas, construction, and cryogenics. However, it is important to note that at extremely low temperatures, steel may become more brittle, which can affect its mechanical properties. Therefore, it is essential to carefully select the appropriate grade of steel and consider any specific requirements or limitations for the intended application when determining the minimum temperature that steel pipes can handle.

- Q: How do you calculate the pipe head loss for steel pipes?

- To calculate the pipe head loss for steel pipes, you can use the Darcy-Weisbach equation. This equation relates the head loss (hL) to the flow rate (Q), pipe diameter (D), pipe length (L), fluid density (ρ), fluid velocity (V), and a friction factor (f). The formula is as follows: hL = (f * (L/D) * (V^2))/(2g) Where: - hL is the head loss (measured in meters) - f is the friction factor (dimensionless) - L is the pipe length (measured in meters) - D is the pipe diameter (measured in meters) - V is the fluid velocity (measured in meters per second) - g is the acceleration due to gravity (usually taken as 9.81 m/s^2) The friction factor (f) depends on the Reynolds number (Re) of the flow, which is a dimensionless quantity representing the ratio of inertial forces to viscous forces. The Reynolds number can be calculated as: Re = (ρ * V * D) / μ Where: - Re is the Reynolds number (dimensionless) - ρ is the fluid density (measured in kg/m^3) - V is the fluid velocity (measured in meters per second) - D is the pipe diameter (measured in meters) - μ is the dynamic viscosity of the fluid (measured in Pa·s or N·s/m^2) The friction factor (f) can be obtained from empirical correlations or from Moody's diagram, which relates it to the Reynolds number and the relative roughness of the pipe surface. By substituting the calculated friction factor (f) and other known values into the Darcy-Weisbach equation, you can determine the head loss in the steel pipe. It is important to note that the head loss is a measure of energy loss due to friction and other factors, and it is typically expressed in terms of pressure drop or height difference.

- Q: What does "DN25 PN16" mean?

- The welded steel pipe can be divided into thin-wall steel tube, ordinary steel pipe and thickened steel tube according to the thickness. Its nominal diameter is neither external diameter nor internal diameter, but a nominal size similar to the diameter of the ordinary steel pipe. Each nominal diameter corresponds to an outer diameter, and the inner diameter varies with the thickness. Nominal diameter can be expressed in metric mm, also available in English in. With nominal diameter pipeline accessories, meaning with tube. "DN25" means the inner diameter of the steel pipe is 25MM.

- Q: What are the factors to consider when selecting pipe materials for high-temperature applications?

- When selecting pipe materials for high-temperature applications, there are several factors that need to be taken into consideration. Firstly, the material's thermal conductivity is crucial. High-temperature applications require materials with high thermal conductivity to ensure efficient heat transfer and prevent heat buildup. Materials such as copper and stainless steel have excellent thermal conductivity and are commonly used in high-temperature pipe installations. Secondly, the material's resistance to thermal expansion is important. When exposed to high temperatures, pipes tend to expand. Therefore, it is crucial to choose materials with low thermal expansion coefficients to prevent deformation and potential pipe failure. Materials like carbon steel and stainless steel exhibit relatively low thermal expansion and are suitable for high-temperature applications. Thirdly, the material's mechanical strength and resistance to corrosion need to be considered. High temperatures can cause certain materials to weaken or corrode, leading to structural failures. It is essential to select materials that can withstand high temperatures without compromising their mechanical strength or corroding easily. Materials like alloy steel and nickel-based alloys are known for their high strength and resistance to corrosion, making them suitable for high-temperature applications. Furthermore, the material's cost and availability should be taken into account. Some high-temperature pipe materials may be expensive or difficult to obtain, which can impact the overall project budget and timeline. It is essential to balance the desired material properties with the project's financial and logistical constraints. Lastly, the specific application requirements and industry standards should be considered. Different industries may have specific guidelines or regulations regarding pipe materials for high-temperature applications. It is crucial to ensure that the selected materials comply with these standards to ensure safety, reliability, and compliance with industry regulations. In conclusion, the factors to consider when selecting pipe materials for high-temperature applications include thermal conductivity, resistance to thermal expansion, mechanical strength, resistance to corrosion, cost and availability, and compliance with industry standards. By carefully evaluating these factors, one can choose the most suitable pipe material to ensure efficient and reliable operation in high-temperature environments.

- Q: Are steel pipes suitable for oil and petroleum applications?

- Yes, steel pipes are widely used in oil and petroleum applications due to their superior strength, durability, and resistance to corrosion. These pipes are capable of withstanding high pressure and extreme temperatures, making them suitable for transporting oil and petroleum over long distances. Steel pipes also have the advantage of being able to withstand external forces such as impact and vibrations, which are common in the oil and petroleum industry. Additionally, steel pipes can be easily welded and connected, allowing for efficient and cost-effective installation. Overall, steel pipes are the preferred choice for oil and petroleum applications due to their reliability and ability to ensure the safe and efficient transportation of these valuable resources.

- Q: What is the difference between steel pipes and concrete-lined pipes?

- The main difference between steel pipes and concrete-lined pipes lies in their composition and protective features. Steel pipes are typically made entirely of steel, providing strength and durability. On the other hand, concrete-lined pipes consist of a steel pipe coated with a layer of concrete. This lining offers additional protection against corrosion and abrasion. While steel pipes are more suitable for high-pressure applications and offer better resistance to external factors, concrete-lined pipes are commonly used in wastewater systems to prevent corrosion and extend the lifespan of the pipe.

- Q: What are the different types of steel pipe coatings for corrosive environments?

- There are several types of steel pipe coatings used for corrosive environments, including epoxy coatings, polyethylene coatings, fusion bonded epoxy coatings, and zinc coatings. These coatings provide a protective barrier against corrosion and extend the lifespan of the steel pipes in harsh conditions.

- Q: Can steel pipes be used for agricultural irrigation?

- Yes, steel pipes can be used for agricultural irrigation. They are durable, resistant to corrosion, and have high tensile strength, making them suitable for transporting water over long distances in agricultural fields. Steel pipes also have the advantage of being able to withstand high pressure, making them ideal for irrigation systems that require efficient water distribution.

Send your message to us

N80-P110 Grade Oil Tubing Direct 13Cr Oil L80 Oil Tubing,Superior Quality High Cost-Effectiveness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords