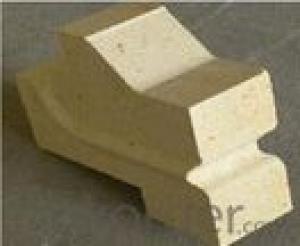

Mullite Brick for Hot Blast Stove with Low Creep Andalusite

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

热风炉用低蠕变红柱石砖

项目 | LHZ—65 | LHZ—60 | LHZ—55 | LHZ—50 |

Al2O3, % | 65 | 60 | 55 | 50 |

显气孔率,% | 20 | 20 | 20 | 20 |

体积密度,g/cm3 | 2.60 | 2.50 | 2.50 | 2.40 |

常温耐压强度,MPA | 50 | 50 | 50 | 50 |

蠕变率,%(20—50h) | 0.2 | 0.2 | 0.2 | 0.2 |

重烧线变化,%(1400℃x4h) | 0—0.3 | 0—0.3 | ±0.2 | ±0.2 |

荷重软化开始温度,℃ | 1650 | 1600 | 1600 | 1580 |

Specification:

Product characteristics; Hot blast stove with low creep brick of andalusite using selected andalusite, corundum, mullite as main raw materials, through high pressure molding, high temperature sintering, andalusite in 1350 ℃ formation of mullite products surface with strong "welding" effect, so that the products good thermal shock resistance, high refractoriness under load, high temperature creep resistant performance is good, good thermal shock resistance, is a Dutch type technical characteristics of hot blast stove with refractory.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- When the bricks are below Al2O3 71.8%, the base of the composition is mullite and SiO2, such as grade LZ-48 bricks. Because it contains a large number of SiO2 formed in the liquid phase under high temperature is 20% ~ 30%; brick in Al2O3 more than 71.8%, the excess Al2O3 formed corundum crystal under high temperature, while generating 2 high temperature phase, eutectic temperature rise by the low content of Al2O3 brick 1595 C to 1840 C, such as grade LZ-75 brick. In fact, it is impossible to produce a complete phase equilibrium in the process of production, but the glass phase is very small, and there is no more than 10% in the partial gap of the Yu Jing phase

- Q: What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity.

- Q: What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- The floor tiles are not made exclusively of alumina. Pure alumina ceramics are expensive.

- Q: What is the price of refractory bricks?

- The construction is superior, the light insulating brick has good machinability, and the construction is convenient and simple, and the labor intensity can be reduced, the construction efficiency can be improved, and the construction period can be shortened. The price is determined by the choice of material and volume density, from several hundred to 5000 yuan, mainly with the choice of material

- Q: Mullite bricks in alumina alumina is what?

- Quality solutionsMullite brick:With mullite as main crystalline phase of high alumina refractory products. Mullite bricks containing Al2O3 64%~75%, refractoriness >1790? C, normal temperature compressive strength 70~260MPa, softening the starting point for 1600~1700 degrees. The manufacturing method for casting and sintering process.

- Q: Jm26 mullite aluminum content in the number, ask God to answer. 23 more. How is this identified with the naked eye?

- Under strong alkaline conditions, aluminum is separated from other metal ions by the amphoteric nature of aluminum.

- Q: The introduction of mullite brick

- General alumina content in 65% ~ 75% between. In addition to mullite, the mineral composition contains lower amounts of glass phase and square quartz, and alumina containing a small amount of corundum.

- Q: Mullite brick

- High refractoriness, up to 1790 degrees celsius. The softening start temperature is 1600~1700 degrees. The compressive strength at normal temperature is 70 ~ 260MPa. Good thermal shock resistance. The sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or raw bauxite as binder, after molding, sintering and made. Fused mullite brick with high bauxite, alumina and refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite is larger than that of sintered mullite, and the thermal shock resistance is better than that of sintered products. Their high temperature performance mainly depends on the content of alumina and the uniformity of the phase distribution of mullite and glass. [1]

- Q: What are the varieties of polycrystalline mullite?

- PNF-100 seriesThe PNF-100 series are made of polycrystalline mullite fiber cotton felt to cut, compress, and wrap into blocks without any adhesive.Characteristic: thermal shock resistancelow thermal conductivityLight weightSound absorption propertyLow thermal storage

- Q: Refractory bricks (mullite bricks) can be used on the walls of buildings?

- Mullite refractory bricks can be used in construction, but their price is too high. We choose high alumina brick to meet the demand.

Send your message to us

Mullite Brick for Hot Blast Stove with Low Creep Andalusite

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords