Torsion Spring, long-service life

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5T pc

- Supply Capability:

- 151000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Torsion Spring:

1) Dimensions:

a) Wire diameter: 0.15 ~ 65mm

b) Thickness: 0.15 ~ 20mm

2) Long service-life

3) Good hardness

4) Good resistance to both high and low temperatures

5) Can be used in various corrosive mediums

6) Main material: carbon spring steel, alloy spring steel,

refractory steel, stainless steel, high temperature

resisting alloy, corrosion-resistant alloy and bronze

7) Widely used in automobiles, motorcycles, electrical

appliances, telecommunication, communication,

aviation, space and other civil fields

Inner packing: plastic or PE bags

Outer packing: corrugated cartons, wooden boxes or pallets

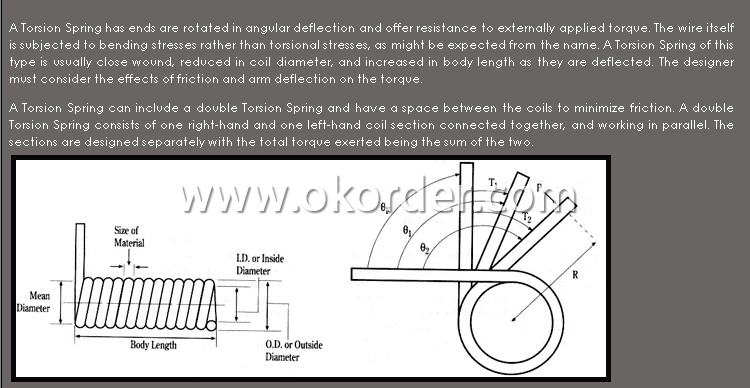

How the torsion springs work?

Packaging Of Our Products

- Q: Is spring steel manganese steel?

- Spring steel is not manganese steel, there are many kinds of spring steel, manganese 65 is more commonly used spring steel, as well as carbon spring steel and alloy spring steel.Manganese steel refers to the high manganese content of carbon steel structural steel.

- Q: Stainless steel and spring steel hardness, who is hard?

- You should say that the deformation resistance, spring steel generally high strength, large deformation resistance, generally speaking, stainless steel generally than spring steel deformation easier, and some varieties of stainless steel deformation resistance is also very large

- Q: Spring dynamometer and spring balance what is the difference

- The principle is similar, but the uses are somewhat different

- Q: What is spring pressure and height?

- Press the compression spring to the point where each circle is tight. Press it and press it high

- Q: What kind of production equipment does spring factory usually have?

- Spring testing machines; fatigue testing machines; torsion testing machines; spring tension and compression testing machines

- Q: What is flat steel? Plain carbon flat steel? Spring flat steel

- Section steel is one of the four major steel products (plate, tube, mould, wire). According to the section shape, the section steel is divided into simple section steel and complex section steel (deformed steel). The former refers to the steel, round steel, flat steel, angle steel, six angle steel; the latter refers to the I-beam, channel steel, steel, steel, steel frame bending etc.. Square, square section steel, cold and hot points in two; length of hot-rolled square steel 5-250mm; cold drawn steel length 3-100mm. Round - round section steel, hot, forged and drawn three, hot-rolled bar diameter 5-250mm, which 5-9mm used as drawing steel wire material, called wire; due to disk supply is also called hot rod. Forged round steel is thicker, used as axle billet. Cold drawn round steel diameter 3-100 mm, high dimensional accuracy. Flat - width 12-300mm, thickness 4-60mm, cross section is rectangular and with pure edge of steel. Flat steel can be finished steel, or can be used as the blank of welded pipe and thin slab for laminated sheet rolling. Angle steel -- two kinds of grade angle steel and unequal angle steel. The dimension of angle iron is expressed by the dimension of the length of side and the thickness of edge. The standard angle steel, usually produced, is 2-20, which is the centimeter side length. Such as 5 equal angles, that is, the length of 5cm (50mm) angle steel. The same horn steel often has 2-7 different edge thickness. Steel bars are not the classification of profiled steel. First, the basic concepts of ferrous metals, steels and nonferrous metals are briefly introduced before introducing the classification of steels, ferrous metals, steels, and nonferrous metals. 1. Ferrous metals are alloys of iron and iron. Such as steel, pig iron, iron alloy, cast iron and so on. Steel and pig iron are both...

- Q: How to choose spring steel material?

- In determining the cross-section shape and size of spring materials, priority should be given to rejection of the national standards or ministerial standards for size specifications, as far as possible to avoid the use of non-standard specifications of materials. Although the spiral spring square or rectangular cross section material, the elastic deformation can be higher than, can make the small volume of the spring, for spring, in small space or under impact load but because of square or rectangular section material shortage, the price is higher, and the spring forming is difficult, so should be avoided. Ring section spring material diameter series see table 3-9.

- Q: How should we choose the spring material?

- In the small spring should be used after hardening spring steel wire, cold drawn steel wire and lead bath oil tempered steel wire with high strength and good surface quality, fatigue performance is higher than the ordinary tempered steel wire, simple processing, good manufacturability, quality and stability.

- Q: How about the size of the elasticity?

- Stretch by the object, extrusion and elastic deformation, the elastic solution is to look at the state of the object, at rest or in uniform linear motion of an object according to the stress analysis of the relationship between the force and other force, curve movement or acceleration force balance objects can analyze the stress in Newton's second law for, no matter what type of stretch can use the two methods to solve the hope to adopt: -)

- Q: In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2001 |

| Annual Output Value | more than US$ 5 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

| Company Certifications | ISO/TS 16949; ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | About 170 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | About 35,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Torsion Spring, long-service life

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5T pc

- Supply Capability:

- 151000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords