MJ-N-2L/3L/4L 2 Lane/3 Lane/4 Lane N-fold Towel Folder

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

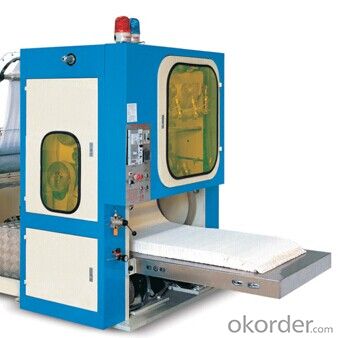

MJ-N-2L/3L/4L Automatic N-Fold Towel Folders uses the Towels (wet strength tissue) as materials to emboss, cut and then fold into N-shaped towels, which can be easily drawn out one after another from the dispensers or packing boxes. The products are widely used in the hotels, offices and kitchens and it is convenient and hygienic. Based on the company's principle that taking science and technology as treasure and innovation, the machine is another newly products conform to the enterprise's doctrine that making profit by new technology. Each technical target exceeds or reaches the criterion all over China and from abroad. It adopts vacuum suction technology (patent product) and combines the working procedure of folding, slitting, counting, etc. The raw paper is of high adaptability, the speed of the products is high and the quality is high. As it is pushed into the market, the machine is approved by the customer, and it is best choice to increase the output and reduce the cost for the customer.

8Main Characteristics:

1.Capacity: up to 180m/min

2.Steel-to-Steel embossed, pneumatically pressed

3. Adopt the vacuum suction technology, it is newly patent product

4.Pneumatically cut-off and separate paper, it is easy for threading paper

5. Equipped with the timing belt, the transmitting speed is correct, and less noise

6.Add the lubricate oil on key part regularly, for keeping the durability of parts

7.The raw paper size is available, 33-45g/m2(single layer)

8.Equipped with PLC system according to the customer's requirement.(Option)

ITEM | MJ-N-2L | MJ-N-3L | MJ-N-4L | |

Finished products size | 230(L)×225(W)×2mm(other size to be specified) | |||

Jumbo roll diameter | ≥Φ1000mm | |||

Jumbo roll core diameter | Φ76mm(other size to be specified) | |||

Machine speed | 0~180m/min | |||

Programmable controller | MITSUBISHI PLC | |||

Folding type | Vacuum suction | |||

Lubricating system | Automatic lubricating at the main sections in time | |||

Transmission system | Timing belt,chain | |||

Counter system | Electronic counting、ink marked | |||

Embossing unit | Steel to steel,press pneumatically | |||

Slitting system | Pneumatic knives | |||

Vacuum power | 11KW | 18.5KW | 22KW | |

Pneumatic system | 3HP air compressor,mini pressure:5kg/cm2(customer provide) | |||

Power | 3KW | 4KW | 5.5KW | |

Dimension | Depend on configuration | |||

Weight | Depend on configuration | |||

Option | ||||

Machine structure | Complete close structure | |||

Programmable controller | MITSUBISHI PLC,HMI | |||

- Q: What is the design basis of automated packaging?! Just for today!

- 1. each manipulator is controlled by a single computer. A packaging machine for the completion of complex packaging operations, the need to be completed by a number of robot hand. When the package is completed, the information is monitored and controlled by the computer controlled camera, and the manipulator completes the required actions according to the instructions of the computer program to ensure the quality of the packaging.2. high resolution of material and thickness. In the packaging process, the thickness and material change in packaging materials is not easy for the human eye to identify changes in the design of packaging machinery is often used by the computer control of the camera and the detector to identify the thickness of packing material and material. The camera has now been developed to automatically check and identify pictures of the camera and display it on the screen. At present, the machine in the processing speed can not be changed, the future should be based on the change of the material through discrimination can change the speed, so as to control the work in the optimal state, complete the packaging process in the shortest time, and realize the automatic cleaning, automatic sterilization and automatic cleaning

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (1) calculate the average of two samples;(2) the variance of two samples was calculated;(3) which packaging machine is more stable in packing quality?(1) according to the average, the number divided by the sum of each group;

- Q: What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard applies to the use of heat sealing glass paper, BOPP, PVC film and other packaging materials, packaging machine for carton box type items or single package or bag or several stacked and wrapped sealing, widely used in food, medicine, tobacco, cosmetics, stationery, audiovisual products etc.. This standard needs to be purchased.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

Send your message to us

MJ-N-2L/3L/4L 2 Lane/3 Lane/4 Lane N-fold Towel Folder

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords