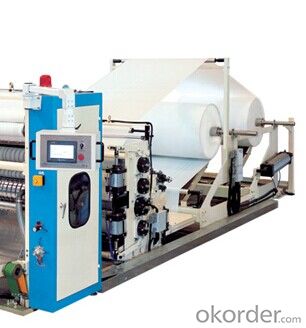

MJ-N-SJ-2L/3L/4L/5L 2 Lane/3 Lane/4 Lane/5 Lane Lamination N-fold Towel Folder

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

MJ-N-SJ Series automatic N-fold Gluing Towel Folder is the latest model for gluing and folding of three fold hanky towel, the two ply low grammage tissue can be laminated by gluing, to increase the volume, hydroscopicity and softness of the finished products.

ITEM | MJ-N-SJ-2L/3L/4L/5L |

Finished products size | 230(L)×225(W)±2 mm; |

Jumbo roll diameter | ≥Φ1100mm |

Jumbo roll core diameter | Φ76mm(other size to be specified) |

Machine speed | 0-100m/min(depend on model) |

Programmable controller | MITSUBISHI PLC,HMI |

Folding type | Vacuum suction,”N”folded |

Lubricating system | Automatic main parts regular lubricating |

Transmission system | Timing belt,flat belt |

Counter | Electronic counting and ink marked |

Embossing unit | Pneumatic pressure,cross embossing or in-phase embossing |

Lamination system | Point to point gluing or cross gluing |

Slitting system | Pneumatic slitting knives |

Machine structure | Standard structure,complete close structure |

Vacuum power | 11-32KW(depend on machine model and configuration) |

Pneumatic system | 3HP Air Compressor,mini pressure:5kg/cm2(customer provides) |

Power | 7.5-15KW(depend on machine model and configuration) |

Dimension(mm) | 7000×(1730-2450)×1850 depend on machine model and configuration |

Weight | depend on machine model and configuration |

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: What is the delay time of the packer's cross sealing?

- The sealing time is how long the delay is when the sealing dies are joined together.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: What does the mechanical equipment include?

- Track roller type rail flat car track car battery car nailThese are, want to know more, you can go to the network building equipment to see there

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- English Name: Transparent, film, fold, wrapping, machineClassification: machinery, general machinery and equipment, >>J83 storage equipment, loading and unloading machineryICS classification: packing and conveying of goods, >>55.200 packaging machinery

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

MJ-N-SJ-2L/3L/4L/5L 2 Lane/3 Lane/4 Lane/5 Lane Lamination N-fold Towel Folder

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords