Application: Laser Engraving

Condition: New

Laser Type: CO2

Engraving Area: 260*320mm

Engraving Speed: 500mm/s max

CNC or Not: Yes

Cooling Mode: Water Cooling

Applicable Material: Acrylic, Crytal, Glass, Leather, MDF, Paper, plastic, Plexiglax, Plywood, Rubber, Stone, Wood

Graphic Format Supported: PLT, DXF, BMP

Place of Origin: China (Mainland)

Brand Name: Raylaser

Model Number: ST40GU

Dimension(L*W*H): 800*530*250mm / 31.5*20.9*9.8 in.

Certification: CE, ISO, FDA, BV

After-sales Service Provided: Overseas service center available

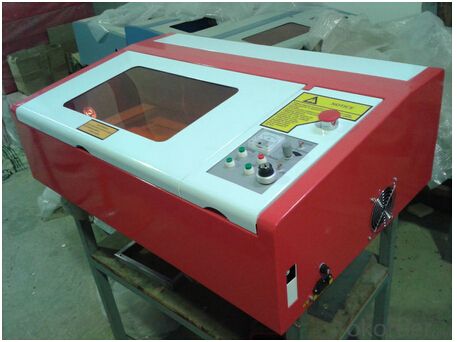

color: red and white

worktable: up and down table

dual red dot pointer: yes

software: Newlydraw/Moshi/CorelLaser

Specifications

laser engraverdual red dot pointer

up-down worktable

CE, FDA certificate

popular overseas

mini crafts Laser Engraver (Desktop), advertising engraving machine,rubber stamp laser engraving machine

Product Description

Model | ST40GU | |

Communication Interface | USB2.0 | |

Working area | 260 X 320mm | |

Laser Power | 40W | |

Engraving Speed | 500mm/s Max | |

Engraving Depth | 1.2mm | |

Cutting Speed | 50mm/s | |

Cutting Depth (Acrylic) | 0-5mm | |

Up and down work table | Manual Up and down 40mm adjustable | |

Minimum Shaping Character | 1 X 1mm | |

Resolution Ratio | 0.0254mm (1000dpi) | |

Power Supply | 220V(or110V)+/-10% 50HZ | |

Resetting Positioning | Accuracy less than or equal to 0.01mm | |

Gross Power | 300W | |

Operating Temperature | 0-45°C | |

Operating Humidity | 35-70°C | |

Graphic Format Supported | PLT/DXF/BMP/JPG/GIF/PGN/TIF | |

Operation System | Windows 98/ME/2000/XP/VISTA/Windows 7 | |

Engraving on Curve Surfaces(Yes/No) | No | |

Slope Engraving | Yes | |

Water Cooling(Yes/No) | Yes | |

Maximum Height Of Materials To Engrave(mm) | 120mm. | |

Laser Tube | Sealed CO2 glass laser tube | |

Machine Dimension | 800*530*250mm / 31.5*20.9*9.8 in. | |

Packing Dimension | 950*670*420mm | 1040*890*540mm |

Gross Weight | 50kgs (carton) | 65kgs (plywood box) |

Standard Accessories: Fan and Exhausting pipe, Power cable, USB cable, Lamp, Water pump, Dual red dot pointer, Software and Dongle, Keys for machine

Spare Parts Recommended: Laser tube, Reflection lens and Focus lens

Warranty: 24 Months for machine (3 months for laser tube and mirrors and lens)

Application: Seal/stamp marking, Present/gift, art work, advertising industry etc.

Optional: Air pump