Mill Finish Aluminum Coil 3003 H22 China Factory Direct Supply in Pensacola

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum 3003 H22 China Factory Direct Supply

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminum 3003 H22 China Factory Direct Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum 3003 H22 China Factory Direct Supply

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

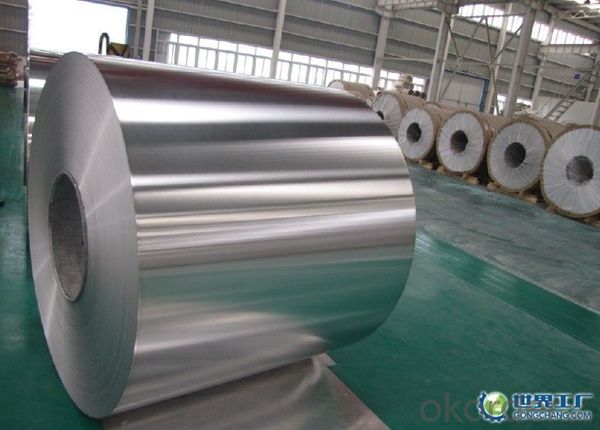

5. Image of Mill Finish Aluminum 3003 H22 China Factory Direct Supply

6. Package and shipping of Mill Finish Aluminum 3003 H22 China Factory Direct Supply

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the safety measures one should take when using aluminum coils indoors?

- <p>When using aluminum coils indoors, it's crucial to ensure proper ventilation to prevent the buildup of gases that can be harmful if inhaled in large quantities. Always follow the manufacturer's guidelines for installation and operation. Keep the coils away from flammable materials and ensure they are securely fastened to prevent tipping or falling. Regularly inspect the coils for any signs of damage or wear, and replace them if necessary. Never use aluminum coils in enclosed spaces without proper exhaust systems, and always have a fire extinguisher nearby in case of emergencies.</p>

- Q: I know aluminum has gone up in price. I know very little about gutter material. Durability, leaf guards, etc. I am on a limited income, and need the most and best for my few bucks. Thanks Lee

- Go with aluminum seamless gutter ,plastic only comes in 10 ft lenghts so you would have more seams which means more chances of it leaking A easy formula to figure out whataluminumn gutter will cost is and it goes by linear footage so measure your house where gutters would go and then add 12 LF for each downspout you will need about 4 and you have the total and if you call a contractor they will give you a free estimate but it should cost you about $2-$3 a Linear foot everyone is hurting for work so get a couple bids and go back and forth for the best price Also leaf guard is expensive about $4 a LF look for similar products that are cheaper hope this helps

- Q: This question asks for the cost of an aluminum coil, which can vary based on factors such as weight, quality, and market conditions.

- <p>The cost of an aluminum coil can vary significantly based on its weight, grade, and current market prices. As of my last update, the price per pound can range from about $0.30 to $1.50, but this is subject to change with market fluctuations. For precise pricing, it's best to check with a supplier or on a commodity exchange, as aluminum prices are dynamic and influenced by global supply and demand.</p>

- Q: Is it possible to utilize aluminum coil in the welding process?

- <p>Yes, aluminum coil can be used for welding. It is commonly used as a filler material in processes like MIG (Metal Inert Gas) welding, where it is fed continuously into the weld pool to create a joint. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need to prevent oxidation. The aluminum coil must be of high quality and clean to ensure a strong, corrosion-resistant weld.</p>

- Q: How are aluminum coils protected from damage during transportation?

- Aluminum coils are protected from damage during transportation through various measures such as using protective packaging materials like plastic or wooden crates, securing them with straps or bands to prevent movement, and using padding or cushioning materials to absorb shocks and vibrations. Additionally, coils may be wrapped in protective films or coated with anti-corrosion agents to safeguard them from environmental elements during transit.

- Q: Explain how aluminum coil interacts with magnetic fields and what effects can be observed.

- <p>Aluminum coil itself does not have a direct relationship with magnetic fields in terms of magnetic properties, as aluminum is not a magnetic material and does not get magnetized. However, when an aluminum coil is part of an electrical circuit, it can interact with magnetic fields in the context of electromagnetic induction. If a changing magnetic field passes through an aluminum coil, it can induce an electromotive force (EMF) or voltage in the coil, according to Faraday's law of electromagnetic induction. This induced voltage can cause an electric current to flow through the coil if it is part of a closed circuit. The aluminum coil's primary interaction with magnetic fields is thus through the generation of electrical current when used in conjunction with an electric circuit.</p>

- Q: How do aluminum coils compare to titanium coils in terms of weight?

- Aluminum coils are generally lighter in weight compared to titanium coils.

- Q: Can aluminum coils be used in high-vibration environments?

- Yes, aluminum coils can be used in high-vibration environments. Aluminum is a lightweight and flexible material that can withstand and absorb vibrations effectively. It is commonly used in various industries, including automotive and aerospace, where high-vibration environments are prevalent. Additionally, aluminum coils are often designed and manufactured to have enhanced durability and resistance to vibration-related issues such as fatigue and cracking.

- Q: How much is one square aluminum gate and five hard door?

- Double layer aluminum alloy, in the middle of the 5 bars, ordinary white or beige is 215, a square, the motor, in addition, the general 600KG copper core motor has 550 sets, there are 680 sets.

- Q: Besides replacing all the aluminum wiring.

- First find out the Electrical Codes for your city or area. Some don't allow aluminum and you have to have it up to code. Give a call to your city building permit departing and just ask how to find out about the electrical codes for the city first and see if you can recover them, replace them or have an electrician do the work. Tell them you have a friend who is calling about buying a house that has aluminum wire outlets and don't give any information. Building codes may be listed on a town or county's web site or read up on it. Once you know what's allowed, you can decide what to do about it. remember, always be very careful with electricity.

Send your message to us

Mill Finish Aluminum Coil 3003 H22 China Factory Direct Supply in Pensacola

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords