Microporous Insulation Board 0.035W/m.k Much Lower Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

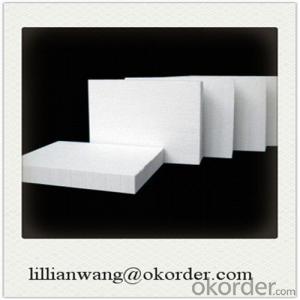

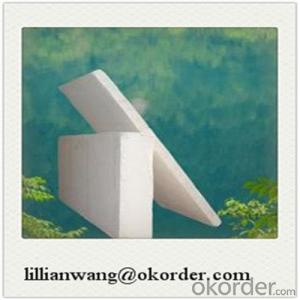

Low Conductivity Microporous Insulation Board (0.035W/m.k.)

Product Description:

CMDS Microporous Insulation Board is a microporous technology product, and is made up of a specific blend of filament reinforced fumed silica, which provides superb thermal performance.

It is an ideal back & shy insulation for various industries where high temperatures are needed, or extended exposure to 1150°C.

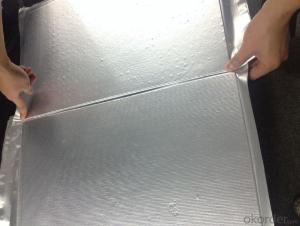

STD can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

Main Product Features:

· Extremely low thermal conductivity

· High thermal stability

· High thermal stability

· Environment protection

· Easy to handle

· No harmful inhalable fibers

· Resist most chemical attacks

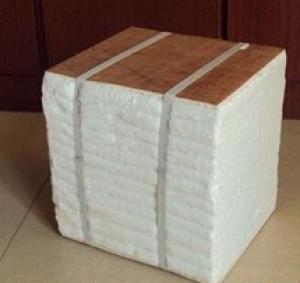

Products Images:

Products Specifications:

Minimum Order Quantity: | 1200 pc | Unit: | pc | Loading Port: | Shanghai |

Supply Ability: | 20000 pc/month | Payment Terms: | TT or LC | Package: | Pallet |

Product Applications:

Industrial furnaces, fuel cells (SOFC), thermal batteries, Aluminum industry (smelters), glass & ceramics industry, petrochemical industry (cracking furnace, reformer)

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30% T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific orders.

- Q: What are the production methods of calcium silicate board material?

- Calcium silicate (microporous calcium silicate) material and calcium silicate board are produced by static steaming method, dynamic hydrothermal synthesis method and two reaction method.

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab blank (blank off off phenomenon is not forming tube adhesion fingerboard blank above)There are two reasons: one is the blank off the vacuum negative pressure is too large, the blank water is too low, low viscosity; two is felt blocked, the billet made worse.The solution is to reduce the negative pressure, strengthen the cloth washing.

- Q: What are the three major effects of fly ash in concrete?

- The "form effect" of fly ash contains many glass beads, the surface is smooth and the texture is dense. It is this form to water reducing effect, compact and homogeneous effect, can promote the early hydration of cement flocculation effect of solution, change the mixture rheological properties, the initial structure and hardening of the various functions, especially for pumping concrete, can play a good role in lubrication.

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- Calcium silicate board called gypsum composite board, is a kind of porous material, good sound and heat insulation, in indoor air moist circumstance can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort. It is super fire gypsum material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.

- Q: Eterpan and yinte in what is the difference?

- Calcium silicate board:Calcium silicate board is mainly inorganic mineral fiber or cellulose fiber and other loose short fiber materials with siliceous and calcareous materials as the main cementing material, pulping, molding, in high temperature and high pressure saturated steam curing acceleration, sheet formation of calcium silicate gel made.Calcium silicate board is a new type of building and industrial plate with excellent properties. Its products are fireproof, moisture-proof, soundproof, moth resistant and durable. It is an ideal decorative board for ceiling and partition. Excellent waterproof performance, just can prevent the home improvement for a long time damp deformation, especially in the bathroom for a long time in a humid environment, the use of calcium silicate board ceiling is the best choice.

- Q: What are the main use of lime?

- Lime stabilized soil mixes lime powder or lime powder with various crushed or formerly loose soil, and is obtained by mixing, compacting and curing. It is called lime stabilized soil. It includes lime soil, lime stabilized gravel soil, lime crushed stone soil and so on. Lime stabilized soil has a certain strength and water resistance. Widely used as a building foundation, ground cushion and road base.

- Q: What is the main role of fly ash added in concrete products?

- The workability of fresh concrete can be improved by adding fly ashThe workability of fresh concrete is affected by the volume, water cement ratio, gradation, shape and porosity of the aggregate. The fly ash is used for fresh concrete is the obvious benefits of increasing the slurry volume, slurry filled with aggregate between pores, inclusions and lubrication of aggregate particles, so that the concrete mixture has better cohesiveness and plasticity. The aggregate particles of fly ash can reduce the interfacial friction between the paste and aggregate, and improve the workability of the concrete mixture at the contact point of the aggregate.

- Q: Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- The market is generally understood, but in fact, Eterpan belongs to Guangzhou eternit limited production of the 100 year history of eternit brand board, because the cement product is Belgium hetet group invention.

- Q: How to make building glue?

- A building adhesive consisting of 28-50wt% sodium silicate aqueous solution, 34-53wt% quartz sand, and 8-35wt% magnesium silicate. The product of the invention can be used for the bonding of ceramic tile, floor tile, marble, wood and glass in indoor and outdoor decoration of buildings. It can be used as a substitute for cement in the field of tiling. The product of the invention is environment-friendly products without pollution when being produced and used. The utility model has the advantages of low price, strong adhesive force and curing at normal temperature.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Calcium silicate insulation insulation materials in 1980s has been recognized as the massive rigid insulation materials in one of the best, which is characterized by low density, high heat resistance, low thermal conductivity, flexural strength, high compressive strength, low shrinkage. But after entering 1990s, the promotion of the use of a downturn, the main reason is that many manufacturers to adopt in order to solve the problem of non asbestos fiber pulp, pulp fiber and not due to high temperature, thus affecting the thermal insulation material of high temperature resistance and increase the breaking rate, and not the economy.

Send your message to us

Microporous Insulation Board 0.035W/m.k Much Lower Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches