Metalized MBOPP Laminated with Craft Paper for Food Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

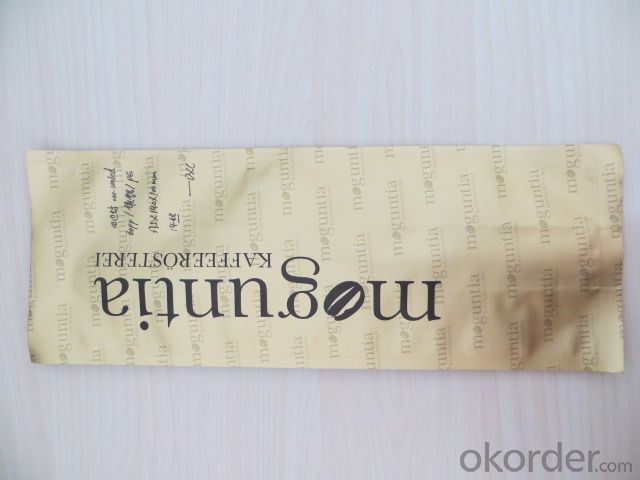

1. Description of Metalized MBOPP Laminated with Craft Paper for Food Packing:

Metalized MBOPP Laminated with Craft Paper for Food Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Metalized MBOPP Laminated with Craft Paper for Food Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Metalized MBOPP Laminated with Craft Paper for Food Packing:

Excellent quality control

Experienced factory produced

SGS passed

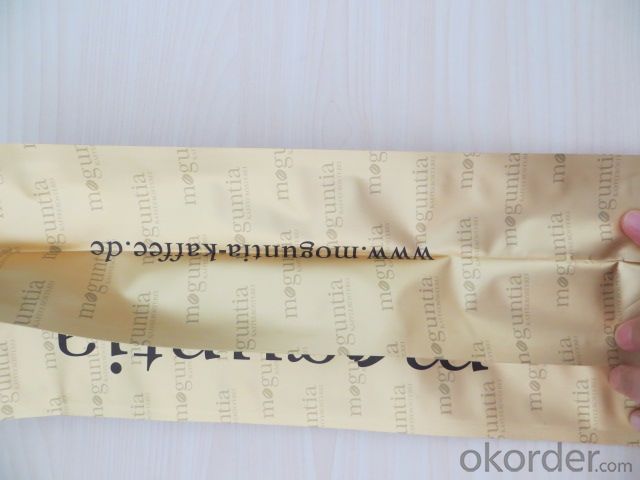

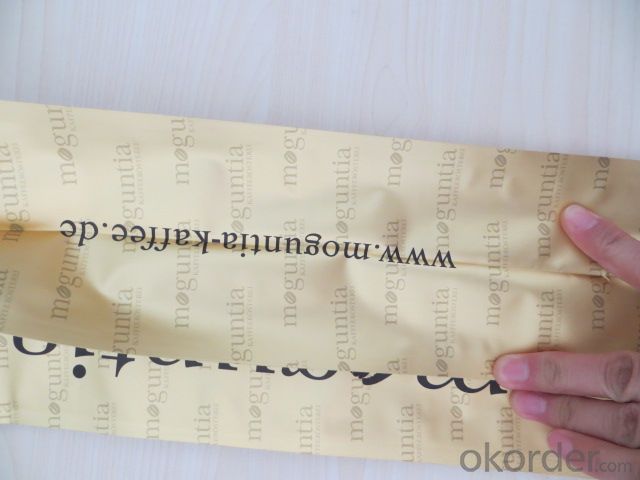

3. Metalized MBOPP Laminated with Craft Paper for Food Packing Photos:

4. Metalized MBOPP Laminated with Craft Paper for Food Packing Specification:

1. Material: PE, LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Metalized MBOPP Laminated with Craft Paper for Food Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- I did, I saw, salted duck, beef and other good packaging, is the use of the former.

- Q: What are the advantages and disadvantages of OPP and CPP membranes? What kind of bags are they used for?

- CPP films have the characteristics of good transparency, high gloss, good stiffness, good moisture resistance, good heat resistance, and easy to heat sealing. CPP film is printed and bag made

- Q: How are food bags made out?

- Packaging design: This is based on the requirements of the food company to design the layout of the food packaging bag, that is, the pattern of food packaging bags. A good design layout of food packaging bags can improve the sales of products. After all, the first eye is still very important. This pattern is generally designed by the food company and then given to the manufacturer of the bags.

- Q: How do you determine the 210mm*300mm package and determine its version and length?

- Length 21 cm, width 30, vertical roll length suggest up to cooperate with compound printing equipment

- Q: Do vacuum packing bags have to be vacuum packed?

- Vacuum packaging bags and vacuum packaging machines are related. Vacuum packaging machine not only can complete vacuum extraction, but also can complete heat sealing packaging in vacuum, and ensure vacuum in vacuum bag can meet the requirement.

- Q: What's the raw material of the cement packing bag?

- The raw material is polypropylene resin cement packaging bags, mainly for foreign production of polyethylene (PE), mainly for the domestic production of polypropylene (PP), then add some additives, after the heating wire drawing, then weaving, printing and so on, the higher the quality of the cement bag inner lining!

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- It's a special packing bag for express delivery. That kind of paper bag, like post office, is specially designed to pack the things you want to express.Wrap things up and seal them in a bag.Some sellers or buyers need such bags when they are delivered. Some express to the seller to buy money.

- Q: What is the difference between LDPE and PE-LD in a package?

- LDPE is a low density polyethylene, environmental protection bag production is one of the raw materials, commonly known as low material, another raw material of HDPE is also called high pressure materials, packaging film, the two materials are mixed according to a certain proportion and then blowing, printing, cutting, packing bag made of,PE-LD is a common environmental protection mark printed on top of the packing bag, which indicates that the manufacturer is using an environmentally-friendly plastic bag.

- Q: What kind of packaging bag does polysilicon use?

- Polysilicon shall be packed in a clean polyethylene packing bag and sealed;

- Q: What ink is the food packing bag printed on?

- Because of this, benzene soluble chlorinated polypropylene ink has been gradually eliminated, and in Europe and other developed countries have gradually introduced or banned the use of benzene soluble chlorinated polypropylene ink laws and regulations.

Send your message to us

Metalized MBOPP Laminated with Craft Paper for Food Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords