Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing:

Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing are processing with imported materials ,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing mainly used in the manufacture of thin films, containers, pipes, wire, wire and cable, and other daily necessities, and can be used as high frequency television, radar and other insulating material. the best choice for all kinds of products ‘packaging.

2. Main Features of Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing:

Bottom Sealed Flat PE Unprinted Bags is Polyethylene odorless, non-toxic, feels like wax, has excellent resistance to low temperature performance (minimum temperature is -70 ~ -100 °C), good chemical stability, erosion resistant to most acids (not resistant to oxidizing acid), at room temperature not soluble in common solvents, water absorption, excellent electrical insulation properties.

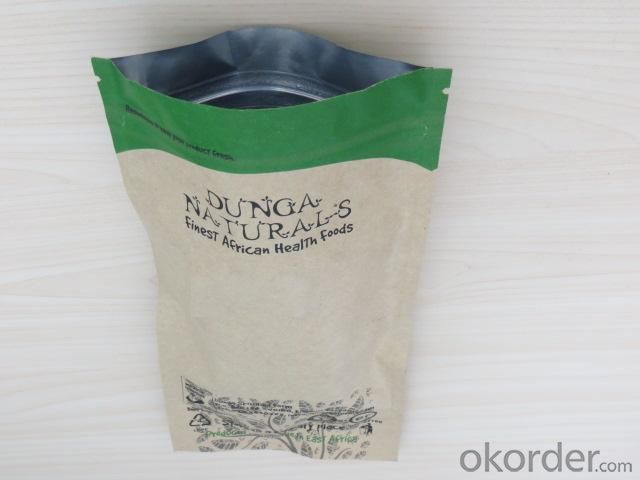

3. Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing Images:

4. Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing Specification:

1. Material: Laminated material

2.Size:20*750px or Customized

3.Thickness:0.03mm-0.15mm

4.Form:top open bag,ziplock bag, or Unprinted bag

5.FAQ of Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is the packet in the food package a reducing agent or an oxidizing agent?

- The ingredients of food reducing agents are some vitamins, phenols, iron powder and so on. Because these substances react readily with oxygen, they protect the food from being oxidized,

- Q: What are the requirements of the mark on the cement packing bag?

- The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents. Bags on both sides should be based on the varieties of cement with different color printing name and cement strength grade, Portland cement and ordinary portland cement Portland slag cement by using red, blue gray volcano; Portland cement and Portland fly-ash composite silicate cement by sleep and black or blue..

- Q: Can food wrap be heated in a microwave oven?

- A package or container that is not suitable for microwave heating:1 metallic or metallic or metallic (absolutely not)2, if the porcelain with metal decorative patterns, it can not.3 、 special plastic for non microwave oven and special plastic film for non microwave oven.4, all containers that do not indicate microwave heating are not recommended.

- Q: Do vacuum packing bags have to be vacuum packed?

- Vacuum packaging bags and vacuum packaging machines are related. Vacuum packaging machine not only can complete vacuum extraction, but also can complete heat sealing packaging in vacuum, and ensure vacuum in vacuum bag can meet the requirement.

- Q: What kind of material is the food packing bag in general?

- Custom food vacuum packaging bag, I recommend to have food vacuum packaging bag manufacturers customized experience, because it can reduce the cost and time for many of you, can give you a lot of packaging design and customized recommendations.

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- Aluminum filmThe first consideration of food packaging is the barrier properties of packaging materialsBecause barrier property is good, the preservation time is long, the shelf life is long, the quality can guarantee betterAt present, all food packaging materials, aluminum foil barrier is the best (followed by some high polymer plastics, like EVOH, PVDC, etc.)Therefore, the most common, always in the middle of two layers of plastic film, a layer of aluminum foil, to improve barrier,But why not use aluminum foil packaging alone, but also two or more layers of plastic film?,

- Q: What kind of packaging bag does polysilicon use?

- Disposable material into a double-layer polyethylene bag, and then packing bags into the packing box or packaging barrel. Block polysilicon packaging specifications are net 5000g or 10000g per bag.

- Q: Plastic packing bag printing color

- A few colors, that is, a few colors, with several roll, one color needs a roll, and the more colors you have, the higher the cost of making the plate. Of course, the plate is calculated by area, the greater the size of your area, the higher the cost of making.

- Q: How many kinds of packing bags are there in the packaged foods?

- You ask about food plastic packaging, it is generally packaged with composite bags, composite materials, polyethylene (PE), polypropylene, nylon, polyester. These are the main membranes. The film is made of stretch film and blow film. Dry frozen goods, generally cooked with PET/PE., such as high temperature, it is generally nylon, composite CPP, or other composite, many kinds. I am in Dongguan, Humen, food packaging, such as alcoholic peanuts, bags, red dates bags, mask packaging bags, washing powder bags, areca bags, milk powder bags, small fish bags.

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- More importantly, the use of aluminum foil / composite or polyethylene composite or aluminum foil / polyethylene composite material. Although this type of packaging is opaque, it protects against loss of vitamin B1 in bread.

Send your message to us

Matt Bopp Laminted with Craft Paper with Zipper Closer for Food Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords