Metal Cans Filling and Sealing Machine with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

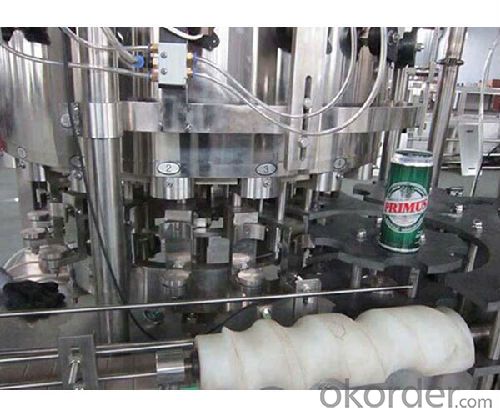

Metal Cans Filling and Sealing Machine

This machine is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. It is a pop canned Beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development Of the can filling, sealing unit. Filling and sealing is the overall designed, power system by filling sealing system to Ensure that both the absolute synchronization and coordination. It adopts the advanced machine, electrical equipment, and Pneumatic control technology.

It has the characteristics of filling reposefully, high speed, liquid level control, capping Reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the Customers request.It is the preferred equipment for the medium beer and beverage plant.

2. Images

3. Main Features

Steady and high quality

Fast shipment

Good experience for export work

4. Specifications

Metal Cans Filling and Sealing Machine Main Technical Parameters

Type:Filling Machine

Application:Beverage

Packaging Type:Bottles

Packaging Material:Metal

Rated Output(335ml bottle):8000BPH

Compressed Air Consumption:0.05m 3/min

Filling Valve Head Count:18

Filling Valve Flow Rate:>150ml/s

Power:3.75KW

Model Number:YCG

Dimension(L*W*H):3150×1730×2700mm

Weight:3500 KG

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (3) large variance, indicating that this group of data volatility, variance is small, volatility is relatively stableAnswer: (1) a = x (501+500+503+506+504+506+500+498+497+495), 10=501,B = x (503+504+502+498+499+501+505+497+502+499), 10=501;(2) S2, =1/n[(501-501) 2+ (500-501) 2+... + (495-501) 2]=12.6,S2 B, =1/n[(503-501) 2+ (504-501) 2+... + (499-501) 2]=6.4;(3) a b > S2 dreams S2,The quality of R B packaging machine 10 bags of sweets is relatively stable.Comments on the subject, mainly on the average number, variance calculation, and their significance, the correct memory formula is the key to solving problems

- Q: What machine does the packing carton machine have?

- Packaging equipment including: automatic strapping machine, automatic sealing machine, winding (wrapping) machine, sealing and cutting / shrink machine, vacuum packing machine, automatic strapping machine band and hand tools. Transport equipment mainly include: conveyor belt, roller conveyor, conveyor chain plate, plug-in production line, chain conveyor, conveyor belt etc..

- Q: What's the best place to use the pillow type packing machine?

- In the early communication can be reflected, and sometimes non-standard customized to see the level of Technology

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- You can send me a picture of your product and the process, so that I can answer your question exactly. More than 70% of the candies on the market are now automatically packed.

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Different conceptsCompression molding refers to hot forming: mainly for thermoplastic materials (sheet), the use of hot forming machine, Blister molding, I think it should also be considered as a branch of hot stamping, vacuum or high-pressure gas will be used to assist. Hot pressing sheet forming a relatively small depth, relatively simple structure, low precision products, such as packaging materials, plastic pallets, plates in the dishes and so on. There are also forming plate pressing molding (lamination)

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

Send your message to us

Metal Cans Filling and Sealing Machine with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords