Melt Extract Stainless Steel Fiber Reinforced Concrete Wire with Glued Steel Fibers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland), Shandong, China (Mainland)

Model Number: GLUED, glued steel fiber

Material: Steel

type: steel fiber for concrete reinforcement

material: steel wire

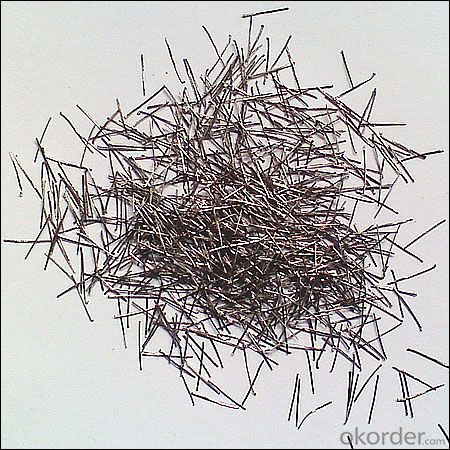

shape: glued together in a row

appearance: clear and bright

Product features

1>steel fiber

2>tensile strength: >1000Mpa

3>wire diameter:0.5mm-1mm

4>standard: ASTM A820

5>20 years factory

hook ends steel fiber, Corrugated steel fiber,Wavy Steel Fiber, steel fiber reinforced, stainless steel fiber, etc.

steel fiber are for concrete construction, greatly improves concrete bonding,etc.

Specifications

length :20-60mm

diameter :0.5MM-1.2MM

tensile strengh:>1100Mpa

| diameter | length | tensile strength | |

| 0.5mm | 35mm | 1100Mpa | |

| 0.75 | 60mm | 1100Mpa | |

| 0.9 | 60m | 1100Mpa |

Picture

PP bag

any type

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

Steel Fiber Glued for Construction and Concrete Wire Diameter

- Q: Can melt extract stainless steel fiber enhance the resistance of concrete to chemical attack?

- Concrete's resistance to chemical attack can be enhanced by melt extract stainless steel fiber. Stainless steel fibers are well-known for their excellent corrosion resistance, durability, and high melting point. By adding these fibers to concrete, they function as reinforcement, increasing its overall strength and resistance to various forms of degradation, including chemical attack. Chemical attack on concrete occurs when aggressive substances, such as acids, alkalis, or salts, come into contact with the concrete surface. This can result in the deterioration of the concrete, including loss of strength, cracking, and eventual failure. However, by incorporating melt extract stainless steel fibers into the concrete mix, the concrete's resistance to chemical attack is significantly improved. The stainless steel fibers create a network within the concrete, which serves as an additional barrier against the penetration of aggressive chemicals. This network helps prevent the diffusion of ions and the entry of moisture, both of which are crucial factors in chemical attack. Additionally, the stainless steel fibers function as reinforcement, enhancing the overall durability and strength of the concrete. Moreover, melt extract stainless steel fibers possess a high melting point, enabling them to withstand the elevated temperatures that can arise during chemical reactions. This ensures that the fibers do not melt or deteriorate when exposed to aggressive chemicals, guaranteeing their effectiveness in enhancing the concrete's resistance. In conclusion, the addition of melt extract stainless steel fiber to concrete significantly improves its resistance to chemical attack. These fibers' corrosion resistance, durability, and high melting point make them an effective reinforcement against aggressive substances, enhancing the concrete's overall durability and lifespan.

- Q: Can melt extract stainless steel fiber be used in precast tunnel segments?

- Yes, melt extract stainless steel fiber can be used in precast tunnel segments. These fibers are commonly used in precast concrete products as they provide reinforcement and improve the overall durability and strength of the structure. Melt extract stainless steel fibers have high tensile strength and excellent corrosion resistance, making them suitable for use in harsh environments, such as tunnels. They can enhance the crack resistance and impact resistance of the tunnel segments, thus increasing their longevity and reducing maintenance needs. Additionally, the use of stainless steel fibers can help improve the fire resistance of the tunnel segments, ensuring the safety of the structure and its occupants. Overall, melt extract stainless steel fibers are a reliable and effective solution for reinforcing precast tunnel segments.

- Q: Does melt extract stainless steel fiber improve the abrasion resistance of concrete?

- Yes, melt extract stainless steel fiber does improve the abrasion resistance of concrete.

- Q: How does the dosage of melt extract stainless steel fiber affect its performance in concrete?

- The dosage of melt extract stainless steel fiber has a significant impact on its performance in concrete. The dosage refers to the amount of fiber added to the concrete mixture, and it affects various properties of the concrete, including its strength, durability, and crack resistance. When the dosage of stainless steel fiber is increased, it leads to an increase in the overall tensile strength of the concrete. This is because the fibers act as reinforcement, distributing the tensile forces and preventing the formation and propagation of cracks. Higher dosages of stainless steel fiber can significantly improve the flexural strength of the concrete, making it more resistant to bending and reducing the risk of failure under load. Additionally, the dosage of stainless steel fiber affects the concrete's durability. By increasing the dosage, the concrete becomes more resistant to chemical attacks, such as corrosion from chloride ions or sulfate attack. This is due to the protective barrier created by the stainless steel fibers, which inhibit the penetration of harmful substances into the concrete matrix. Moreover, the dosage of stainless steel fiber influences the crack resistance of the concrete. Fibers provide bridging effects across cracks, preventing them from widening and reducing crack propagation. Higher dosages of stainless steel fiber can enhance the crack control ability of the concrete, resulting in improved overall performance and service life. However, it is essential to note that there is an optimal dosage range for melt extract stainless steel fiber. Excessive dosage can lead to issues such as fiber balling, which hinders proper dispersion in the concrete mixture. This can negatively impact the workability of the concrete and may result in an uneven distribution of fibers, compromising their effectiveness. In conclusion, the dosage of melt extract stainless steel fiber significantly affects its performance in concrete. By increasing the dosage within the optimal range, the concrete's tensile strength, durability, and crack resistance can be improved. Careful consideration of the dosage is crucial to achieving the desired concrete properties while avoiding potential issues associated with excessive fiber content.

- Q: How does melt extract stainless steel fiber improve the resistance to spalling in shotcrete?

- Melt extract stainless steel fiber is able to improve the resistance to spalling in shotcrete due to its unique properties and characteristics. When added to the shotcrete mix, the stainless steel fibers become distributed evenly throughout the concrete matrix, creating a three-dimensional reinforcement network. This network helps to enhance the overall toughness and ductility of the shotcrete, making it more resistant to cracking and spalling. The high tensile strength of stainless steel fibers allows them to effectively bridge any micro-cracks that may form in the shotcrete during the curing process or due to external forces. By bridging these cracks, the fibers prevent them from propagating and developing into larger cracks, which can ultimately lead to spalling. This bridging effect significantly improves the durability and longevity of the shotcrete. Additionally, the uniform dispersion of stainless steel fibers in the shotcrete helps to inhibit the formation of localized stress concentrations. These stress concentrations are often the initial points of failure in shotcrete, leading to spalling. By evenly distributing the fibers, the stress is more evenly distributed throughout the concrete matrix, reducing the likelihood of spalling. Furthermore, the corrosion resistance of stainless steel fibers is paramount in improving the resistance to spalling. Shotcrete is often used in harsh environments where it may be exposed to chloride ions or other aggressive chemicals that can corrode the reinforcing materials. Stainless steel fibers exhibit excellent corrosion resistance, ensuring that the shotcrete maintains its integrity and resistance to spalling over time. In summary, melt extract stainless steel fiber improves the resistance to spalling in shotcrete by creating a three-dimensional reinforcement network, bridging micro-cracks, reducing stress concentrations, and providing corrosion resistance. Its addition to shotcrete enhances its toughness, ductility, and overall durability, making it a reliable solution for applications where spalling resistance is crucial.

- Q: How does melt extract stainless steel fiber enhance the resistance of concrete to corrosion?

- Melt extract stainless steel fiber enhances the resistance of concrete to corrosion through its unique properties and characteristics. When added to concrete as a reinforcement material, stainless steel fiber acts as a barrier against corrosive agents and prevents their penetration into the concrete matrix. One of the main reasons why stainless steel fiber is effective in enhancing corrosion resistance is its high corrosion resistance itself. Stainless steel is composed of iron, chromium, and other alloying elements that create a protective oxide layer on its surface. This oxide layer acts as a shield against corrosive elements such as chloride ions, which are one of the main causes of corrosion in concrete structures. As a result, the stainless steel fiber prevents the penetration of chloride ions into the concrete, reducing the risk of corrosion. Furthermore, the presence of stainless steel fiber in concrete also improves the overall durability and lifespan of the structure. Stainless steel fibers help to increase the tensile strength and flexural strength of concrete, making it less prone to cracking or spalling. By reinforcing the concrete matrix, stainless steel fiber enhances its ability to withstand external loads and environmental factors, including corrosive agents. Additionally, stainless steel fiber has a high aspect ratio, meaning it is relatively long and thin. This characteristic allows the fibers to create a three-dimensional reinforcement network within the concrete, improving its resistance to cracking and reinforcing its overall structure. This network of fibers also acts as a physical barrier that prevents the movement of corrosive elements, such as water and oxygen, within the concrete, further reducing the risk of corrosion. In conclusion, melt extract stainless steel fiber enhances the resistance of concrete to corrosion by providing a high level of corrosion resistance, improving the overall durability and lifespan of the structure, and creating a three-dimensional reinforcement network within the concrete. These properties make stainless steel fiber an effective solution for enhancing the corrosion resistance of concrete structures, ultimately increasing their longevity and reducing maintenance and repair costs.

- Q: Can melt extract stainless steel fiber be used in railway track construction?

- Yes, melt extract stainless steel fiber can be used in railway track construction. Stainless steel fibers are commonly used as reinforcement in concrete applications due to their high strength and durability. They provide additional tensile strength to the concrete, improving its resistance to cracking and enhancing its overall performance. In railway track construction, where the tracks are subjected to heavy loads and constant vibrations, the use of stainless steel fibers can help increase the longevity and stability of the tracks. Additionally, stainless steel fibers are corrosion-resistant, which is a crucial factor in railway track construction as the tracks are often exposed to harsh environmental conditions. Overall, the use of melt extract stainless steel fiber in railway track construction can contribute to the strength, durability, and longevity of the tracks.

- Q: Is melt extract stainless steel fiber compatible with different types of curing methods?

- Yes, melt extract stainless steel fiber is compatible with different types of curing methods. Its high temperature resistance and durability make it suitable for both heat curing and chemical curing methods. Additionally, its excellent corrosion resistance ensures compatibility with various curing agents and processes.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced shotcrete?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced shotcrete. Stainless steel fibers are commonly used in shotcrete applications due to their high tensile strength, corrosion resistance, and durability. The melt extract process ensures uniform and consistent fiber properties, making it suitable for reinforcing shotcrete. The addition of stainless steel fibers to shotcrete enhances its mechanical properties, such as flexural and impact strength, crack resistance, and ductility. This improves the overall performance and longevity of the shotcrete structure. However, the specific application requirements, fiber dosage, and mix design should be considered to ensure proper and effective utilization of the stainless steel fibers in the fiber-reinforced shotcrete.

- Q: Can melt extract stainless steel fiber be used in architectural shotcrete applications?

- Architectural shotcrete applications can indeed make use of melt extract stainless steel fiber. It is a common practice to incorporate stainless steel fibers into shotcrete mixes for the purpose of improving the final concrete structure's tensile strength, ductility, and durability. Specifically designed for shotcrete applications, melt extract stainless steel fibers effectively enhance the performance of shotcrete, rendering it suitable for architectural projects. By incorporating stainless steel fibers into shotcrete, crack control is provided, resistance to impact and abrasion is increased, durability is improved, and the overall structural integrity of the shotcrete is enhanced. This is particularly significant in architectural applications, where both aesthetic appeal and long-term performance are of utmost importance. Moreover, melt extract stainless steel fibers possess a high aspect ratio, indicating that they have a greater length compared to their diameter. This characteristic allows for superior dispersion and bonding within the concrete matrix, resulting in enhanced crack resistance and overall structural stability. To summarize, melt extract stainless steel fibers can be effectively employed in architectural shotcrete applications. Their addition can bolster the strength, durability, and overall performance of shotcrete, making it a suitable choice for a wide array of architectural projects.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Concrete Wire with Glued Steel Fibers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords