Melamine Faced Sapele Veneered MDF Panels - Straight Wood Grain Chipboard Particle Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

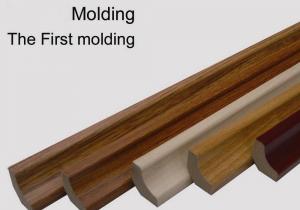

Sliced Cutting Sapele veneered MDF are usually be used in decoration and furniture.

Characters:

Light, easy to install, disassemble and beautiful.

Products Details:

Detailed Specification:

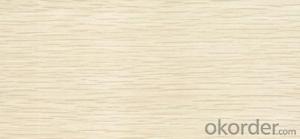

Product name:Sliced Cutting Sapele veneered MDF in straight grain

Size: 1220*2440mm

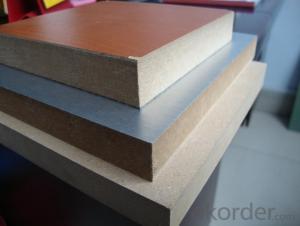

Thickness: 4mm-18mm

length/width tolerance: +/- 0.5mm

thickness tolerance: +/- 0.2mm

glue: E1,E2,E0

moisture: 6~12%

packing: seaworthy export pallet packing,strengthen by steel tape with 3*6 or loose packing in containers

loading quantity: 21.5CBM per 20'container

minimum order quantity: one 20'container

usage: used for furniture

payment term: by T/T or L/C at sight

delivery time: within 20 days after we got your advance payment

2. Packing Details of Sliced Cutting Sapele veneered MDF

Four sides are around with MDF in thickness ≥4mm,

Top cover is thin MDF in thickness ≥ 8mm,

Bottom board is MDF in thickness ≥12mm ,

4+8 steel strips.

FAQ:

Q1. How long can we receive the product after purchase?

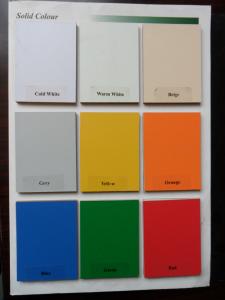

A1: Normally, cargoes can be shipped within 25days if the paper are in fast-moving colors; however, if colors are special need to be matched, then, we need at least one month to prepare and produce

- Q: What are the identification methods for the panel?

- The so-called short plate: wood flooring is often a production process requirements is relatively high, but also has a certain amount of technology on the content of products, while enterprises are also subject to their own conditions to limit , But continue to lead to the floor after the pavement is said to be in a relatively short period of time on the deformation, and that the paint off the contents of the phenomenon.

- Q: Do closet, wardrobe board, what plastic good?

- Compared with the universal latex, it has the advantages of less environmental protection, non-toxic harmless, high final strength, good solvent resistance and heat resistance. Compared with ordinary white latex, it has the advantages of less cloth, quick drying and easy operation , High production efficiency, easy rework (reversible) and so on.

- Q: Will the fire board be used as a plywood for furniture?

- of course. And is a good choice.

- Q: What are the quality requirements for decorative panels?

- Decorative veneer - Material quality requirements: First, depends on the thickness of the decorative panels have reached the specified thickness (commonly used 1mm 2mm the thickest thickness of 3mm different prices, with the exception is also different) Second, Texture direction or pattern as a whole is not a third to see the decorative panel toughness (the bigger the better) Fourth, look at the surface of the decorative panel is smooth

- Q: What is the thickness of the trim panel?

- Decorative panel specifications are a piece of wood made of wood or natural wood sliced, adhere to the plywood surface material.

- Q: Home improvement commonly used plate which?

- Blockboard process: also known as big core board. Is the core and the upper and lower sides of the board (up and down each layer or two layers) glued together from the sandwich board.

- Q: What kind of glue when you use it?

- Wood latex and Wan Nengjiao, (latex is mainly used for the connection of two materials to prevent deformation. Universal glue first with less, and now furniture are like custom. Are mixed oil)

- Q: What are the advantages of ecological boards and other boards?

- Consumers in the selection of such plate furniture, in addition to taking into account the color and texture satisfaction, but also from several aspects to identify the appearance of quality: whether stains, scratches, indentation, porosity, color gloss is not uniform, there is no Bubbling phenomenon, with or without local paper tear or defect phenomenon and so on. If the phenomenon of veneering cracking or damage, you can use the following methods to repair: first in the damaged place to put a damp cloth, and then put a hot iron on the hot cloth, forcing the moisture into the veneer, so that the veneer becomes tough and difficult Fragmentation. So that you can first clean the old plastic, and then coated with a layer of milk at the grass layer of wood, and then in the loose surface of the negative coated with a layer of new plastic, compaction, to be completely dry glue.

- Q: Is the wooden door good for solid wood or plywood?

- Natural environmental protection, which is the biggest feature of solid wood furniture. Compared with those wood-based panels, the amount of glue is relatively small. The amount of plastic with the impact of the environmental impact of the level of furniture.

- Q: What is an ecological board? Can be used to do?

- Ecological board has been widely used in home decoration, plate furniture, cabinets wardrobe, bathroom cabinets and other fields.

Send your message to us

Melamine Faced Sapele Veneered MDF Panels - Straight Wood Grain Chipboard Particle Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords