Particle Board Melamine Faced MDF Board / Laminated MDF / Melamine MDF

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

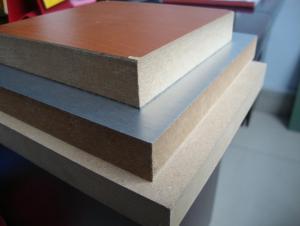

size:1220*2440mm

thickness:2.5-25mm

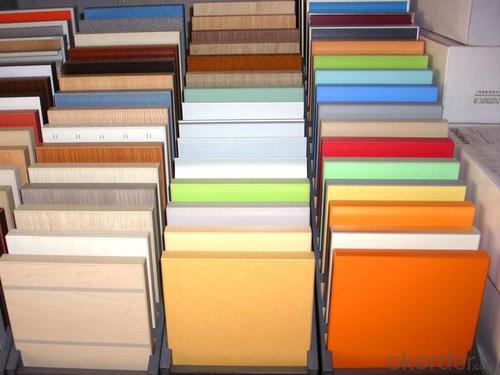

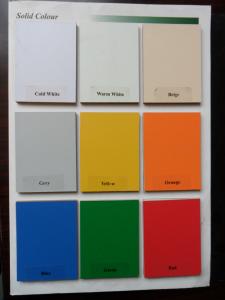

Surface process: Satin, glossy, pearl

| Detailed Product Description | |

| Base board | MDF/MELAMINE |

| Size | 1220*2440mm( 4'*8') |

| Thickness | 2.0mm -30mm , 2.00mm,2.2mm,2.3mm,2.4mm,2.5mm,2.7mm,3mm,3.7mm,4.0mm,4.35mm,4.5mm4.75mm,5.5mm, 9mm,11mm,12mm,15mm,17mm,18mm,25mm |

| Glue | MR, E0, E1, E2 |

| Face&back | Plain board, Melamine paper or veneer, UV, PVC, 1 or 2 sides

|

| Material | Poplar or hardwood |

| Density | 750-830 kg/m³ |

| Moisture | 4%-12% |

| Surface treatment | Matt.Gloosy,Marble.Embossed,Magic etc |

| Usage | Furniture, Construction, Decoration, Door, Flooring, Wall Panel, Packaging, etc. |

| Main market | Middle East, South Asia, South America, Africa |

| Shipment & payment | |

| Port | Qingdao or Lianyungang |

| Packing details | Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength |

| Delivery time | 20 days after receiving advance or L/C at sight |

| Payment | T/T, L/C |

| Advantage | |

| Capacity: 5000 CBM per month | |

| high quality and competitive price, sample available | |

Features

high bending strength

low formaldehyde emission

little linear expansion coefficient

strong nail holding

moisture proof and easy work , moisture content 4%~6.6

FAQ

A. how many sheets for one cubic meter?

Answer:

6mm---56 sheets/CBM

9mm---37.33 sheets/CBM

12mm---28 sheets/CBM

15mm---22.40 sheets/CBM

18mm---18.66 sheets/CBM

21mm---16.00 sheets/CBM

B. how many cubic can load for one container?

Answer:

20FT---21.4 cbm 40ft---37 cbm

- Q: How about the double-pearl board?

- Jinqiu plate has a very good environmental protection, to the international environmental standards E1 level, which comes from its high-quality raw materials and advanced production technology, as well as every aspect of the rigorous testing. Become the industry's "green building materials products."

- Q: What is called a panel?

- Plywood is the trim plywood, is decorated when the furniture (doors, cabinets) used, the specifications are 2.44 meters wide 1.22 meters

- Q: What kind of sheet is the board of the billet board?

- Veneer is the consumption of a large number of labor products, this product is more in developing countries. China's production takes the lead.

- Q: Do closet, wardrobe board, what plastic good?

- After all, posted a layer of panels, more than a plastic, more pollution sources. There are direct blockboard brush varnish, solid wood side of the edge. Good blockboard texture is also very beautiful!

- Q: What is the difference between a melamine plywood and a flat sheet?

- 1. moisture-proof, waterproof

- Q: Do the closet and the door, joinery outside the paste Boeing soft leather and veneer in the performance, quality, visual What is the difference?

- Use the place is not the same, if the decoration inside the paste also, very little so dry. If the hard to compare these two, of course, of course decorated panels, from the performance, quality, vision, cost are better than the Boeing film and expensive.

- Q: What are the quality requirements for decorative panels?

- Decorative panels - the construction quality requirements: First, first of all depends on the floor of the panel is flat, solid Second, depends on the panel texture direction or pattern is not one to third, look at the face of the panel is empty , Look around the panel is not sticky

- Q: Is there a difference between paint and plywood?

- There are differences, most of the paint-free board is attached to the hot PVC film.

- Q: Do you want to paint the panel, what panel?

- Decorated panels, according to their favorite wood grain selection panel, such as maple, white rubber, ash and so on. Come out better.

- Q: Where to do plate, plywood, melamine ecological board, furniture board, can be, it is best to professional point.

- Shanghai, Fengxian District. Risk building materials market. The history of the most professional plate base.

Send your message to us

Particle Board Melamine Faced MDF Board / Laminated MDF / Melamine MDF

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords