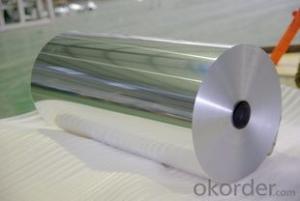

Medicine aluminum foil 8079

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required.

Secification:

Alloy : AA1235/1050/1060/1100/3003/8011/8006/8079/8021etc.

Temper: H14/16/18/22/24/26, HOetc.

Thickness: 0.006mm—0.20mm

Width: 200mm—1600mm(Can be slitted)

Coating: HSL/Primer

Color: Accordingto customers’ requirements

Feature:

100% safe

Environmentally friendly, recoverable and recyclable

Used for storing, packing, grilling/ baking, heating andfreezing

Customized orders available

High-temperature sterilization

Aplication:

Food Packing, Household Application, Cigarette Packing,Lamination, Medicine , Printing, Heat Sealing, Beer Packing, RoofInsulation Materials, Honeycome Materials and so on.

Packaging Detail:

Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

Production Capacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Production Line:

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

40 days after client’s deposit

- Q: Can aluminum foil be used in a microwave oven?

- If your microwave oven features barbecue, such as light wave combination, barbecue key, combination grill, these keys can be used.

- Q: Does it hurt much to work in aluminum foil manufacturing enterprises?

- Through your description, it seems that you have no examples of such contacts in your job (foreign trade is generally foreign sales and the like), so it will not have much impact, usually pay more attention to the line. I guess the company also has the corresponding protective measures to relieve the danger class, ANN

- Q: Can foil be insulated?Indeed, the foil is reflective of the sun's rays

- The use of aluminum foil is very extensive, such as aviation food packaging, cigarette packaging and other packaging ordinary carnivorous. The experts divided it into more than 20 varieties according to its application characteristics. Because of the difference of economic development in different countries, there is a big gap in the consumption structure of aluminum foil. In Europe and the United States, aluminum foil used in packaging accounts for 70% of the total demand. In the Chinese market, aluminum foil is mainly used as raw and auxiliary materials for industrial manufacture. Packaging aluminum foil accounts for only 30% of the total domestic demand. Although the development of aluminum foil packaging is late, the market is growing rapidly and the prospect is interesting.

- Q: What is the specific weight of aluminum foil?

- The proportion of aluminum foil and aluminum ingot consistent, 2.7t/m^3, according to the material of aluminum foil will be slightly different

- Q: The kitchen faucet is placed at the bottom of the cupboard. It has an aluminum foil paper. It smells great. Is it harmful to the human body? How can I get rid of it?

- There is no harm in foil (Aluminium foil), also known as the Hongkong aluminum foil, aluminum foil, aluminum is a metal flat manufacturing tool, mainly used for kitchen cooking, food containers, or used to make some simple cleaning materials. Thousands of tons of aluminium foil are used around the world for the protection and packing of food, cosmetics and chemicals. Most of the foil is shiny on one side and the other dull. Aluminum foil for food can be wrapped on both sides, and it is generally recommended to enhance the heat transfer effect with bright bread wrap

- Q: Outdoor camping in East China, with only one foil damp barrier in the tent, plus sleeping bags? Do you need inflatable mats?

- Aluminum foil are called moisture-proof pad is completely unscrupulous businessmen gimmick. Sit still, sleep really uncomfortable, from warmth and moisture, almost ignored. If you are in a tight position, buy PURELAND's hexagonal foam mat, and if you have plenty of it, buy it yourself. Must not take the body to make fun of, the aluminum foil pad, when I just started playing, all is used to make the ground mat, at that time loves the tent, but absolutely does not have the moistureproof effect.

- Q: What are the application areas of aluminum foil?

- Drug foilMedical package aluminum foil mainly includes water, injection easy to open type bottle cap and medicinal PTP aluminum foil, because PTP aluminum foil has moisture-proof, easy to carry, safe and sanitary, and so on, it is widely used in the international pharmaceutical industry. China began to use the aluminum foil packing drugs since 1985 so far, aluminum foil packaging accounted for only 20% of drug packaging materials, the rapid development of medicine foil market in recent years, on the one hand is the rapid development of the pharmaceutical market, but mainly because the application ratio of 20% aluminum foil in the continuous improvement of the pharmaceutical packaging.

- Q: Aluminum foil will be pervious to light, super light?

- Boxed milk is a lot of paper boxes, there is a layer of aluminum, there is a layer of plastic, this box visible light, I'm afraid it is not easy to pass through, X ray should be able to.

- Q: Clamp aluminum foil paper with sticky?

- ChinaIncluding the heart ballMain ingredients: 750 grams eel, pork (thin) 200 grams, kilogramShrimp accessories: letinous edodes (fresh) 50 grams, pork (hair) 50 grams, 200 grams of sweet potato powder,Spices: soy sauce 10 grams, 5 grams of salt, monosodium glutamate 3 grams, sesame oil 10 grams, 3 grams of pepper, onion 10 grams

- Q: What kind of food grade aluminum foil does it mean?

- You can rest assured that as long as it's food grade, you'll be fine. How many years has it been in foreign countries?,. The choice of food grade, which does not contain harmful metals, such as heavy metals, etc., followed by a high temperature annealing treatment, there is no rolling oil. I just made this. You don't have a little problem with the way you say it, as long as the ingredients are soft. Specifically, the alloy is 8011. Thickness of about 0.015 or 0.02. Width 300 or 450. Rest assured. No problem. I am the manufacturer of aluminum foil. Today, most of China's aluminium foil home appliances are exported to europe.

Send your message to us

Medicine aluminum foil 8079

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords