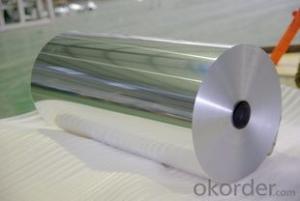

Medicine aluminum foil according to ASTM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Secification:

Alloy : AA1235/1050/1060/1100/3003/8011/8006/8079/8021etc.

Temper: H14/16/18/22/24/26, HOetc.

Thickness: 0.006mm—0.20mm

Width: 200mm—1600mm(Can be slitted)

Coating : HSL/Primer

Color : Accordingto customers’ requirements

Feature:

100% safe

Environmentally friendly, recoverable and recyclable

Used for storing, packing, grilling/ baking, heating andfreezing

Customized orders available

High-temperature sterilization

Aplication:

Food Packing, Household Application, Cigarette Packing,Lamination, Medicine , Printing, Heat Sealing, Beer Packing, RoofInsulation Materials, Honeycome Materials and so on.

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

40 das after client’s deposit

- Q: How to use aseptic packaging aluminum foil bag?

- Foil bag has many advantages over other traditional packaging materials (such as difficult to have superior performance, molding, convenient use, low cost, etc.) as one of the plastic packaging materials, which plays a great role in the development of aluminum foil bag, along with other traditional packaging materials incomparable speed. It has been widely used because of its various shapes and different performances. This is the main characteristic of plastic packing. It can be the ideal performance of various uniform reasonably, such as transparency, thermal stability, physical strength, biological isolation and sealing, radiation resistance, processing and commodity, publicity, protection, use of organically. Together. Make aluminum foil bags as food, beverages, pharmaceuticals and pharmaceutical equipment and other materials, one of the best packaging products, especially in its sealing properties, but also make these products have been well protected and promoted. Although plastic bags of ten rich content, in different poses and with different expressions, but the two most basic forms: one is nothing more than open the packing bag use: such as shopping bags, R bags, Ma Jiadai, hand bags, garbage bags, rope bags, food bags and other packaging bag; seal: such as three edges two side sealing, sealing, sealing the ordinary bags, composite bags and cooking bags etc..

- Q: With aluminum foil wrapped 0.1mol metal sodium in water by needle konza a plurality of small holes, after complete reaction, the volume of gas released (standard) (for)A. cannot determine that B.1.12L C. is greater than 1.12L and D. is less than 1.12L

- The formula is Na+Al+2H 2 O=NaAlO 2 +2H = 2, according to the equation of knowledge

- Q: Some drugs are packed on aluminum foil. What's the use of an empty plastic cover?

- Drugs are generally more fragile, the outer PET packaging is to isolate the first transparent bulge effective bacteria in the air of dust and moisture, prevent the corrosion of infection drugs, the second physical damage effects in the process of drug transport.

- Q: The kitchen faucet is placed at the bottom of the cupboard. It has an aluminum foil paper. It smells great. Is it harmful to the human body? How can I get rid of it?

- Aluminum itself is harmful, long-term consumption of aluminum pollution, who will damage the brain?. When aluminum is usually passivated in the air, it greatly reduces absorption. So it's up to you to decide whether to deal with it or not.In addition, the foil is tasteless, please make sure there is dirt or so on.

- Q: What are the characteristics of aluminium foil waterproof coiled material?

- Aluminum foil paper is soft and easy to change, like paper, and it doesn't bounce after deformation. It can be assured that shading will not fall, light, pollution free and cheap. For high grade cigarettes, sweets and other food moistureproof and decorative packaging.

- Q: Processing method for waste aluminium foil composite film

- Types of decorative materialsCommon types of wooden decorative materials on the market

- Q: Aluminum foil (aluminum foil) heat transfer of heat insulation is how, orThe old radiator looked black and looked uncomfortableA friend suggested wrapped with aluminum foil, has good heat dissipationOn the radiator, aluminum foil feel hot, not hot outHope to get your bachelor's scientific explanationThe foil blocking heat radiationThat is to say, tinfoil radiators (in the case of no gap) will affect the heat, huh

- Your paper can be aluminum, the premise is not to affect the flow of air, when there is a packet of real will, don't heat and there is gap exist.

- Q: The aluminum foil I bought reads, "microwave ovens, be sure to refer to the microwave oven instructions."".My microwave oven has barbecue. With foil wrapped in meat into the microwave oven, how should operate? Is that all right? With a microwave or a light wave?

- The use of aluminium foil:Other parts of the corner pointed wings, chicken or fish head, tail or cake too easy to cook, cover with aluminum foil wrap can achieve the purpose of cooking evenly.

- Q: What are the advantages of carbon coated aluminum foil and copper foil?

- 3, reduce polarization, increase magnification and gram capacity, and improve battery performance. Such as:Partially reduce the ratio of the adhesive in the active material and increase the capacity;? improve electrical contact between the active material and the collector;Reduce polarization and improve power performance.4. protect the collector and prolong the service life of the battery. Such as:? prevent extreme corrosion and oxidation;Increasing surface tension of collector surface and enhancing the easy coating performance of collector;Alternative high cost etch foils or substitute thinner foil for standard foil.

- Q: Black shading and shading of the aluminum foil machine what is the difference

- At the same time, a knitting fabric is formed, which is called warp knitting. The fabric is called warp knitting fabric. The warp knitting machine is called warp knitting machine

Send your message to us

Medicine aluminum foil according to ASTM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords