MDF Board Particle Board - High Quality OSB Board for Building Houses

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction:

OSB Board is usually used as core of Doors,and it is featured as light in weight , sound-proof anti-impact , temperature-keeping and stable in dimensions,

The product reserves the virtues of wood and gets rid of its weak points such as skrinking after being wet ,and being heavy in weight,It is indeed an ideal green enwironment-friendly replacement to solid wood cores.

Pictures:

Packaging & Shipping

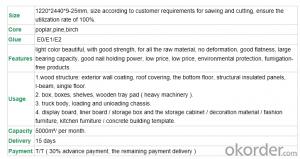

Description:

1)size:2000*125mm,2090*1180mm,2000*900mm

2)Thickness:

6-45mm(9.5mm,11.1mm,12mm,15mm,18mm) or as your request.

3)Core:pine and poplar

4)Glue:E1and E2

5)Density:350-400 kg/m³

Usage: Environmental protection Hollow particle board adopted high-quality imported logs as raw materials. It can be used for door cores, furniture, decorative, partition wall stuffing ,etc

OSB Board Feafures and Advantages:

Strong nail holding

♥ High bending strength

♥ Water-proof, moisture-proof

♥ Anti-corrosion protecting

♥ Strong shock resistance

♥ Low formaldenhyde emission

♥ Good heat and sound resistant

FAQ:

A: What's the main material of hollow chipboard?

B: Poplar and Pine

- Q: What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- Q: The environmental performance of particleboard

- As the particleboard production process, the general use of formaldehyde-based adhesives, so its finished product will release more or less free formaldehyde

- Q: Make the raw material of the particleboard

- Can be pre-pressure and hot-pressing treatment. Preload pressure of 0.2 to 2 MPa, with a flat press or roller press.

- Q: Particleboard in the production process of environmental performance

- to be stored for some time after the observation room. If no spiky smell that particleboard release of formaldehyde less, the use will not affect human health

- Q: Particleboard production process requires proper hot pressing pressure

- Hot mold can be used less rubber or rubber, by lignin in the closed hot mold activation flow from the glue, but need to cooling stripping, heat consumption, low productivity, has been gradually eliminated

- Q: Particleboard by product classification

- . In addition, there are non-wood materials such as cotton stalks, linen, bagasse, rice husk and other made of various particleboard,

- Q: From the appearance point of view

- the length is generally 5-10MM length is appropriate, too long structure loose, too short anti-deformation of the poor, the so-called static bending strength is not compliance;

- Q: Particleboard production requires proper moisture content

- According to the different density requirements of products, hot pressing pressure is generally 1.2 to 1.4 MPa.

- Q: How to improve the particleboard market space

- we must improve the scale of the project construction, the small particleboard factory to reorganize the small particleboard factory in order to improve the quality of the particleboard and reduce the cost and improve the research and development

- Q: The product structure of the wood-based panel industry

- and cutting and processing residues as raw materials, wood utilization rate of nearly 90% of the particleboard ratio

Send your message to us

MDF Board Particle Board - High Quality OSB Board for Building Houses

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords