Matte Packaging Tape - Masking Tape Green Color SGS & ISO9001 Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

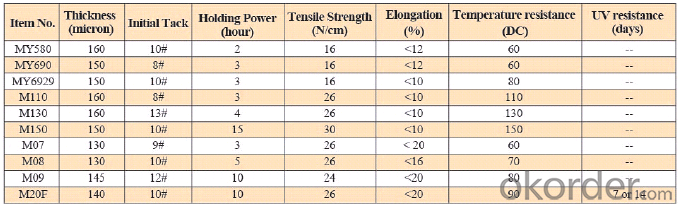

Typical Physical Reports of PVC Electrical Tape

Packaging

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1800mm; width according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Are there any specific instructions for reusing packaging tape?

- There exist specific instructions for reusing packaging tape. Here are several guidelines to adhere to: 1. Exercise caution when removing the tape from the package: Upon receiving a package, make an effort to delicately remove the tape in order to prevent tearing or damaging it. 2. Cleanse the tape: Should the tape possess any dirt, dust, or residue, it can be cleansed by gently wiping it with a moist cloth. Allow it to fully dry before reutilizing. 3. Assess the adhesive strength: Before reusing the tape, verify if the adhesive remains sufficiently strong to securely hold. If it has lost its stickiness or sustained damage, it is advisable to discard it and employ a fresh piece of tape. 4. Properly store the tape: To maintain the tape's quality for future use, store it in a cool, dry area away from direct sunlight. This will assist in preventing it from drying out or becoming brittle. 5. Utilize it for light to medium-duty tasks: Reused packaging tape may not possess the same strength as new tape, therefore it is most suitable for lighter to moderately demanding tasks. Avoid utilizing it for heavy items or applications necessitating a stronger adhesive. Bear in mind, while reusing packaging tape constitutes an excellent approach to waste reduction, it is crucial to prioritize functionality and security. If the tape becomes damaged or loses its adhesive strength, it is advisable to replace it with a new piece to ensure proper sealing of your package.

- Q: Is packaging tape safe to use on delicate items?

- Yes, packaging tape can be safe to use on delicate items as long as it is applied with caution and does not directly touch or damage the delicate surface. It is recommended to use a gentle and removable adhesive tape specifically designed for delicate items to ensure their safety during packaging.

- Q: Can packaging tape be used for sealing packages with electronic components?

- Yes, packaging tape can be used for sealing packages with electronic components. Packaging tape is designed to provide a secure and durable seal for packages, protecting the contents from external elements such as moisture, dust, and physical damage. When sealing packages with electronic components, it is important to ensure that the tape is strong enough to hold the package together and provide adequate protection. It is also recommended to use anti-static packaging tape specifically designed for electronic components, as it helps dissipate static electricity and prevent any potential damage to sensitive electronics.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Yes, packaging tape can be used for sealing packages with high-value contents. Packaging tape is specifically designed to securely seal packages, providing protection against tampering, moisture, and damage during transit. It is strong, durable, and often features a strong adhesive backing that creates a long-lasting seal. When applied properly, packaging tape can effectively secure packages containing high-value contents, ensuring their safe delivery. However, it is important to consider additional security measures, such as using tamper-evident tape or adding extra layers of protection, depending on the value and fragility of the contents.

- Q: Can packaging tape be used for sealing pharmaceutical or medical supplies?

- Yes, packaging tape can be used for sealing pharmaceutical or medical supplies. However, it is important to ensure that the tape is compatible with the specific requirements of the supplies and adheres securely to maintain proper hygiene and prevent contamination.

- Q: Can packaging tape be used for sealing medical or pharmaceutical supplies?

- Packaging tape is not typically recommended for sealing medical or pharmaceutical supplies. Medical and pharmaceutical supplies require a higher level of sterility and protection from contamination. Packaging tape may not provide the necessary level of security and protection needed for these supplies. Instead, medical and pharmaceutical supplies are typically sealed using specialized medical-grade packaging materials such as medical adhesive tapes, tamper-evident seals, or sterile packaging. These materials are specifically designed to meet the stringent requirements of the healthcare industry, ensuring the integrity and safety of the supplies. Using packaging tape for sealing medical or pharmaceutical supplies can compromise their sterility and increase the risk of contamination, which could have serious consequences for patients' health. It is crucial to adhere to industry standards and guidelines when it comes to the packaging and sealing of medical and pharmaceutical supplies to maintain their quality and safety.

- Q: Can packaging tape be used for sealing packages with confidential or sensitive contents?

- Packaging tape can be used for sealing packages with confidential or sensitive contents, but it is not the most secure option. For enhanced security, it is advisable to consider using tamper-evident or tamper-resistant packaging solutions, such as security tape or specialized envelopes, to provide an additional layer of protection against unauthorized access or tampering.

- Q: Is packaging tape resistant to extreme pressure or weight?

- Packaging tape is designed to provide a strong and secure seal for packages, but its resistance to extreme pressure or weight can vary depending on the specific type and quality of the tape. Generally, packaging tapes are made from durable materials like polypropylene or polyester that can withstand typical handling and transportation pressures. However, it is important to note that packaging tape may not be able to withstand extremely heavy loads or excessive pressure. In such cases, it is recommended to reinforce the tape with additional layers or use specialized heavy-duty tapes that are specifically designed for high-pressure or weight-bearing applications.

- Q: Is packaging tape safe to use on leather?

- Packaging tape is not recommended for use on leather. While it may temporarily hold leather pieces together, using packaging tape can cause damage to the leather over time. The adhesive on packaging tape can leave behind residue that is difficult to remove and can stain or discolor the leather. Additionally, the strong adhesive can weaken the leather, leading to tears or permanent damage. It is best to use leather-specific adhesives or methods when working with leather to ensure its longevity and preservation.

- Q: Does packaging tape come in different dispenser designs for ergonomic use?

- Yes, packaging tape does come in different dispenser designs that are specifically created for ergonomic use. These designs focus on providing a comfortable grip and reducing strain on the hand and wrist during tape application.

Send your message to us

Matte Packaging Tape - Masking Tape Green Color SGS & ISO9001 Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches