Clear BOPP Packaging Tape 72mm for Masking in Various Decoration and Waterproof Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

General Purpose Easy Tearing Masking Crepe Paper Tape

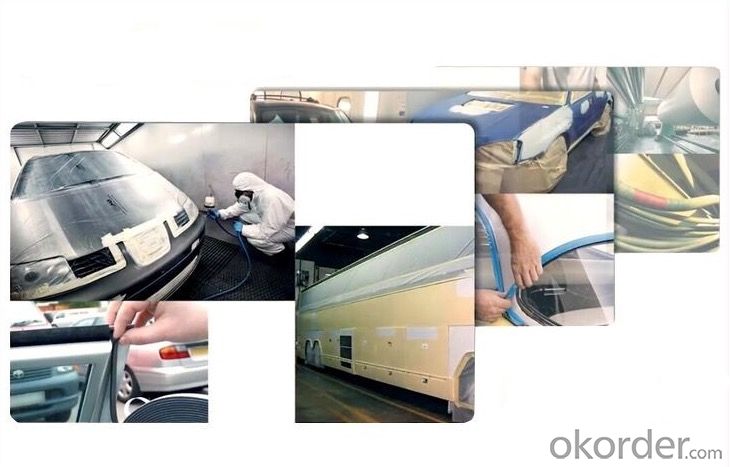

Heat resistant Masking Tape with Paper Attached Crepe Paper Tape consisting a crepe paper backing, coated with high temperature resistant rubber adhesive. Protection and masking in automotive painting.

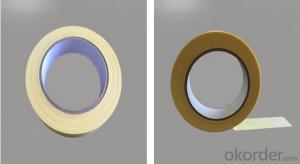

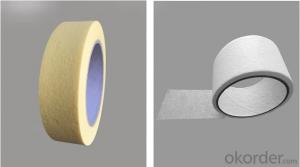

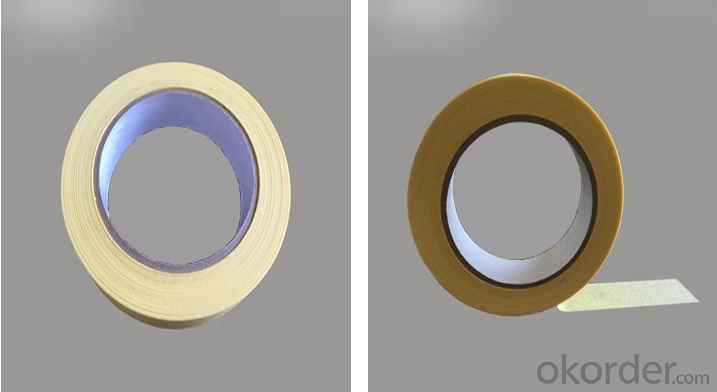

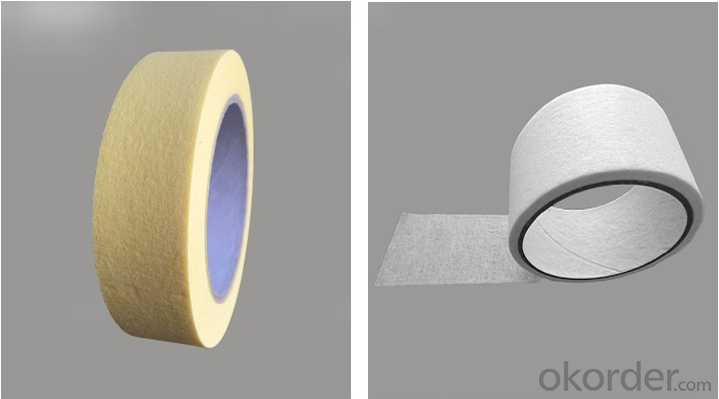

2. product show

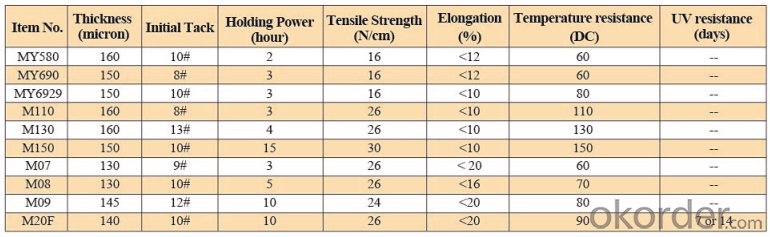

3.Product Specification:

Brand Name | CMAX |

Product Name | Masking Tape General Purpose |

Place of origin | China Beijing |

Carrier | Crepe Paper |

Adhesive | Rubber |

Standard Size | 24mm x 30m, 48mm x 30m, 0.99m x 1800m etc |

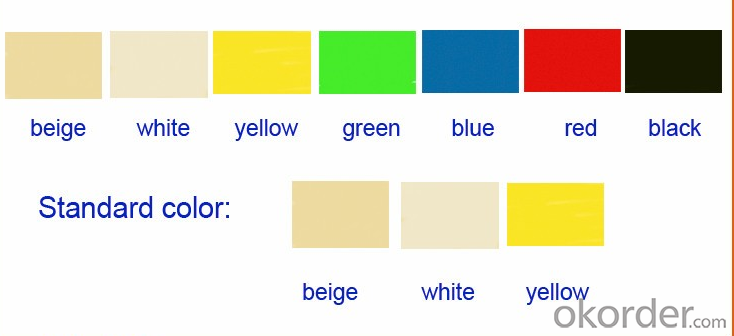

Color | White, yellow, red, green, orange and customized |

Type | General used |

Adhesive Side | Single Sided |

Design Printing | Offer Printing |

4.Application:

They are widely used in the baking process in automobile industry, hardware industry, electronic industry and electric appliances for fixing and protection purposes.

We have exported our products to many countries, such as USA, Japan, Middle East, Russia, Thailand, South Africa, and South America. They are very popular in these countries.

5. Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

6.Our services

1.OEM Service

Your own design is appreciated; we can make the approval sample according to your golden sample.

2. QC Service

a) Before the order to be confirmed, we should check the material & color of fabric by sample which should be strictly.

b) We will be tracing the different phase of production from the beginning.

c) Every bad quality will be checked & cleaned before packing.

d) Before delivery clients could send one QC or point the third party to check the quality.

e) We will try our best to help clients when problem occurred.

3. After-sale Service

a) EXW, FOB, C&F are also available for us.

b) If the products need certificate, we can also provide.

- Q: How to adjust the tightness of belt pulley in belt sealing machine?

- The side sealing machines and other series sealing machines are light, durable and easy to operate. The key component of the widely applicable packing machine is the drive motor

- Q: Can packaging tape be used for labeling?

- No, packaging tape is not typically used for labeling as it is primarily used for securing packages and boxes during shipment.

- Q: Is packaging tape transparent?

- Yes, packaging tape can be transparent. Many types of packaging tape are made from clear materials such as polypropylene or acrylic, allowing them to be see-through. This transparency is beneficial as it allows users to easily see the contents of a package without having to open it. Additionally, transparent packaging tape is often preferred in situations where a clean and professional appearance is desired, as it blends in well with various types of packaging materials. However, it is important to note that not all packaging tapes are transparent, as there are also colored or printed options available for specific purposes or branding needs.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. It is designed to adhere to various surfaces, including painted surfaces, without causing damage or leaving residue when properly applied and removed. However, it is always recommended to test a small, inconspicuous area first to ensure compatibility and to handle the tape with care to avoid any potential paint or finish peeling.

- Q: What course of packing and cartons do we use for our company?

- Raw material ledger ledger should set the number of value type according to the material specifications, if material specifications more, in order to prevent errors but also in warehouse and category raw materials two accounts, two accounts only income issued andbalances amount, do not remember the number.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Yes, packaging tape can be used for sealing packages with high-value contents. However, it is important to ensure that the tape used is strong, durable, and tamper-evident to provide adequate security and protection for the valuable contents.

- Q: What materials are commonly used for packaging tape?

- Packaging tape is an essential tool used for securing and sealing packages for shipping, storage, or general handling. It is made from various materials, each with its own unique characteristics and advantages. The most commonly used materials for packaging tape include: 1. Polypropylene (PP): This is the most widely used material for packaging tape due to its affordability and versatility. It is a durable thermoplastic polymer that offers excellent resistance to moisture, chemicals, and UV radiation. PP tape is available in different thicknesses and can be transparent or colored. 2. Polyvinyl Chloride (PVC): PVC tape is known for its superior strength and durability. It is resistant to water, chemicals, and extreme temperatures, making it suitable for various environments. PVC tape is often used for heavy-duty applications or when extra security is required. 3. Polyester (PET): PET tape is made from a strong and durable synthetic polymer that offers excellent tensile strength and resistance to tearing. It is commonly used for heavy packages or in applications where high strength is crucial. PET tape is also resistant to UV radiation and moisture. 4. Paper: Paper-based packaging tape is an eco-friendly alternative to plastic tapes. It is made from renewable resources and is recyclable. While paper tape may not be as strong as plastic-based tapes, it still provides sufficient adhesion for lightweight or non-fragile packages. Additionally, paper tape can be easily torn by hand, which can be convenient for users. 5. Gummed Tape: Also known as water-activated tape or reinforced tape, gummed tape is made of kraft paper with starch-based adhesive on one side. It requires water to activate the adhesive, creating a strong bond that is tamper-evident and resistant to tampering. Gummed tape provides a secure seal and is often used for heavy packages or in industries where security is a top priority. Overall, the choice of packaging tape material depends on the specific requirements of the application, such as package weight, environmental conditions, and desired level of security.

- Q: Does packaging tape have a specific adhesive strength?

- Yes, packaging tape does have a specific adhesive strength. The adhesive strength of packaging tape refers to how well it sticks to surfaces. This strength is typically measured in ounces per inch (oz/in) or pounds per inch (lb/in). The adhesive strength of packaging tape is determined by various factors, such as the type of adhesive used, the thickness of the tape, and the quality of the backing material. Different types of packaging tape may have different adhesive strengths to cater to specific needs, such as lightweight packages or heavy-duty shipments. It is important to consider the intended use and the weight of the package when choosing packaging tape with the appropriate adhesive strength.

- Q: How do I choose the right packaging tape for my needs?

- Choosing the right packaging tape for your needs can be an important decision to ensure your packages are securely sealed during transit. Here are a few factors to consider when selecting the appropriate packaging tape: 1. Strength and durability: Consider the weight and nature of your packages. If you are shipping heavy or bulky items, opt for a tape that offers high tensile strength and can withstand rough handling. Look for tapes made from materials like fiberglass or reinforced with polyester fibers. 2. Adhesive type: Different packaging tapes use various types of adhesives. Acrylic adhesive is common and offers a good balance of performance and affordability. For more challenging surfaces or extreme conditions, consider hot melt adhesive, which provides superior bonding strength. Additionally, water-activated tape, also known as gummed paper tape, is a great option for added security as it forms a permanent bond when moistened. 3. Width and length: Determine the appropriate width and length of tape based on the size of your packages. Thicker tapes are generally more durable, while longer rolls may be more cost-effective for high-volume packaging. 4. Transparency and aesthetics: If you require your packages to have a professional appearance or if you need to see the contents of the package easily, opt for a clear or transparent packaging tape. However, if appearance is not a concern, choosing a colored tape can help with easy identification or branding purposes. 5. Environmental considerations: If you are conscious of your carbon footprint, look for packaging tapes made from eco-friendly materials or those that are recyclable. Some tapes are also water-based, solvent-free, or made from renewable resources, making them a greener choice. 6. Dispenser compatibility: Consider the type of tape dispenser you have or plan to use. Make sure the tape you choose is compatible with your dispenser, as some tapes require specific types of dispensers. 7. Cost: Finally, compare prices and consider your budget. However, keep in mind that sacrificing quality for a lower price may result in inadequate tape performance and potential package damage. By considering these factors, you can make an informed decision and choose the right packaging tape that best suits your needs, ensuring your packages arrive securely and intact.

- Q: What are the common price ranges for packaging tape?

- The pricing of packaging tape varies based on the type, brand, and quantity of tape you are buying. Basic packaging tape typically costs between $2 and $10 per roll, with lower quality or smaller rolls being cheaper. Mid-range packaging tapes, which may offer better durability or adhesive strength, can be priced from $5 to $20 per roll. Premium or heavy-duty packaging tapes, commonly used for industrial or professional purposes, can range from $10 to $30 per roll. Additionally, you can find bulk packaging tape options that come in packs of multiple rolls, which may have slightly discounted prices. To get the best deal, it is important to consider your specific packaging requirements and compare prices from different suppliers.

Send your message to us

Clear BOPP Packaging Tape 72mm for Masking in Various Decoration and Waterproof Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches