Price of Marine Plywood 3/4 Film Faced Plywood with Poplar Core and Hardwood Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

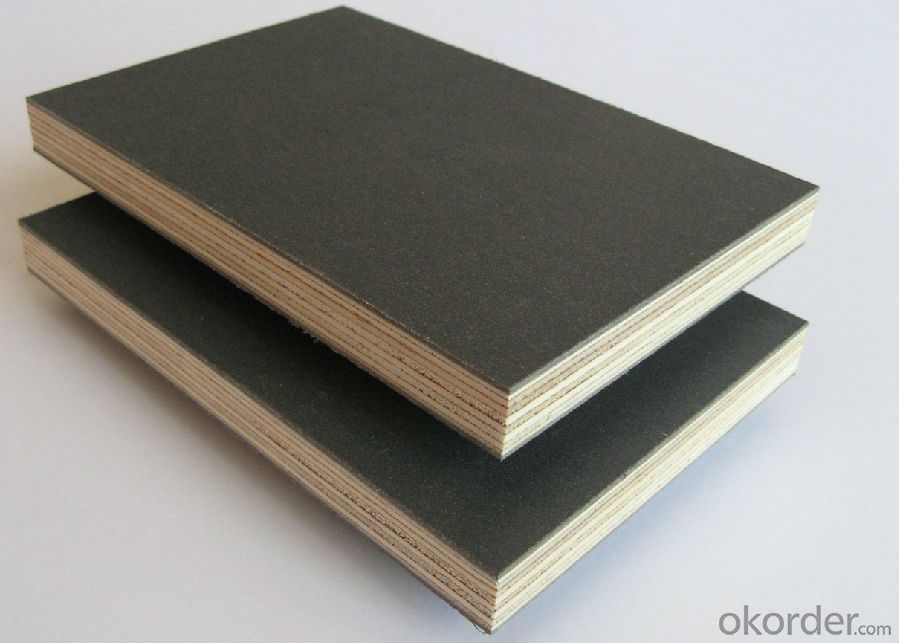

15mm film faced plywood for construction

1.Size: 1220x2440/1250x2500mm

2.F/B: Black/Brown/red

3.Core: Poplar, Hardwood

Description

Marine plywood | ||

Film | Brown film, Black film | |

Core | Poplar, hardwood, pine and others | |

Glue | WBP,Melamine,MR | |

Size(mm) | 1220*2440, 1250*2500, or requested by customers | |

Thickness(mm) | 6-27mm | |

Density | >550-650g/CBM | |

Moisture | 8-12% | |

Modulus of Elasticity | >6000Mpa | |

Modulus of rupture | >30Mpa | |

Quantity | 20GP | 8 pallets/21M3 |

40GP | 16 pallets/42M3 | |

40HC | 18 Pallets/53M3 | |

Min Order | 1*20 ft container | |

Payment | T/T or L/C at sight | |

Delivery time | Within 2 weeks after receiving deposit or Original L/C at sight | |

Addition | Sample available | |

Packaging & Delivery

| Packaging Detail: | Inner with waterproof plastic bag, outside with 3mm plywood and carton, then fastened with 3'x6' sheet iron and packed with pallets |

| Delivery Detail: | 15 days after receiving your deposit or LC |

Features:

1.No wapping, no fracture,not out of shape, it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and it will not pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make construction in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould, it can be processed into different types.

FAQ

1.Q: Supply several kinds of products in your company?

A: We supplies Commercial plywood,film faced plywood,OSB,LVL and other wooden boards.

2.Q: Can the company name and trademark to be printed on the plywood

products or package?

A: Your company name and trademark can be printed on your plywood products or package.

3. Can I visit your factory to inspect the goods for the order?

A:Welcome to my company ,we expect to build long term cooperation with you in the process.

4. Q: What’s your advantages?

A: 1.We are professional in the manufactureing plywood(we have two own factories,One for OSB one for plywood)

2.We have good experience for exporting

3.We can offer you competitive price with lowest cost but good quality

4. Long term business is our first choice, Quality is our first target.

5. We have excellent control system of quality and cost, there is a Special Quality Inspection Team in our company,Each member has at least 10 years of working experience, they can ensure all the products sent to our clients are first-class.

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- the minimum number of layers of each nominal thickness to comply with the relevant provisions.

- Q: Contemporary plywood market development

- as well as foreign high-quality hardwood wood constantly added for the Chinese plywood industry's continuous development To provide a wealth of raw materials; adequate human resources,

- Q: The Decorative veneer veneer plywood grade classification

- To remind manufacturers and other forms of consumer do not meet the requirements of China's decorative veneer veneer plywood standards

- Q: What is a joinery board?

- Blockboard thickness specifications for the 16,19,22,25 mm quality grade is divided into one, two, three three levels

- Q: What are the advantages and disadvantages of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: For the plywood environmental advice?

- Phenolic glue: moisture, excellent resistance to boiling, weather resistance / can be used for outdoor or indoor, can withstand outdoor wind and rain.

- Q: Solid wood and plywood which is better?

- the difference between selection: multi-layer solid wood flooring due to take into account the different species of "alternative heterosexual", so that the production process can fully balance the "internal stress"

- Q: Does plywood contain formaldehyde?

- Home plywood is a commonly used material. Plywood is the wood shavings and urea formaldehyde resin pressed together

- Q: The usual length and width specifications are:

- Solid wood refers to pure solid wood, that is, all materials are not re-processed natural materials, do not use any furniture made of wood furniture.

- Q: What are the types of veneer veneer veneer?

- Decorative veneer veneer plywood according to the decorative surface can be divided into single-sided veneer veneer plywood and double-sided veneer veneer plywood;

Send your message to us

Price of Marine Plywood 3/4 Film Faced Plywood with Poplar Core and Hardwood Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords