Manual Frame Struction Concrete Placing Boom

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

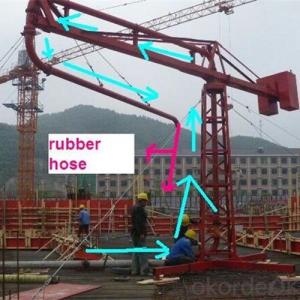

Manual Frame Struction Concrete Placing Boom

PARAMETERS

Manual concrete placing boom parameters

| |||

Specifications | 12meters manual | 15meters manual | 18meters manual |

The big arm design | Dual channel | Dual channel | Dual channel |

Radius of gyration (m) | 12 | 15 | 18 |

The height of the placing boom | 5 | 5 | 5 |

Diameter of conveying pipe (mm) | 125 | 125 | 125 |

Leg span (m) | 3.2*3.2 | 4*4 | 4*4 |

Rotation Methods | Manual | Manual | Manual |

The whole weight (kg) | 1100 | 1200 | 1300 |

With weight (kg) | 600 | 800 | 1000 |

Slewing bearing type | 315 | 315 | 380 |

Material | Channel angle | Channel angle | Channel angle |

Slewing range | 360° | 360° | 360° |

CHARACTERISTICS

1. Frame arm structure, increasing the loadingcapacity and stability.

2. Highquality rotary bearing, flexible rotation

3. Doublesupporting leg, improve the stability and bearing capacity of double

4. Withexcellent steel GB, the Firmness is Enhanced several times compared to Angleiron

5. Minimal impact on the appearance of vibrationforce

6. Withfour rope, ensure that the safety of product using.

PIPE SPECIFICATIONS

| 12M Concrete Placing Boom | ||

Name | Specifications | Quantity |

| Straight Pipe | 3.67M | 1 |

| 4.24M | 1 |

| 5.6M | 1 |

| Delivery Bend | 148-148 R275 90° | 2 |

| 157-148 R275 90° | 1 |

| R500 * 90° | 1 |

| 15M Concrete Placing Boom | ||

| Name | Specifications | Quantity |

| Straight Pipe | 3.67M | 1 |

| 5.56M | 1 |

| 5.8M | 1 |

Delivery Bend | 275*90 add pipe | 1 |

| 148-148 R275 90° | 1 |

| 157-148 R275 90° | 1 |

| R500 * 90° | 1 |

| 18M Concrete Placing Boom | ||

| Name | Specifications | Quantity |

| Straight Pipe | 3.7M | 2 |

| 3M | 1 |

| 7M | 1 |

| Delivery Bend | R500 90° | 1 |

| R275 90° | 1 |

| R275 90° +130 | 1 |

| 157-148 R275 900 | 1 |

Delivery& packing & payment

1. FOB Tianjin or others.

2. Delivery time: within 15 days.

3. Packing: Export standard packing , Seaworthy packing,or according to the customer demand

4. Payment term: T/T, L/C.

5. MOQ: 1 set or according the actual situation.

- Q: What are the specifications of concrete spreader?

- Rotary: rotary, rotary and double rotary bearings; is a kind of new construction machinery and supporting the use of concrete conveying pump tube

- Q: How to install and use the distributor?

- Construction cable must be overhead or buried in the ground, not flat and put. Construction work should be overhead, not line and wire to be flooded or buried by earth and stone. No wires should be tied to steel cage or other iron support at will

- Q: What are the acceptance items of concrete spreader?

- The installation site should be carried out in advance according to the requirements of construction site should be collected, must be stable and firm installation, foot pad.

- Q: What is a fixed concrete distributor?

- Mobile concrete cloth machine "Z" shaped section three folding arm, 360 degree rotation, pitching and folding can achieve full amplitude, pouring in three-dimensional space within the length range of the arm, without pouring dead, can easily realize the concrete pouring construction, wall pipe, the column of various

- Q: What are the weekly inspection items for concrete spreader?

- Check connection bolts, shaft end plate, pin shaft, lock nut is loose

- Q: What is the working principle of the distributor?

- In order to ensure the safety of the work procedure, prevent the cloth machine from tipping over and pay attention to the stability of the frame of the distributing machine, the construction can be carried out

- Q: What is the Hand operated concrete distributor?

- Concrete spreader is a new product developed in order to enlarge the pouring range of concrete and improve the level of pumping construction mechanization

- Q: What are the monthly inspection items of the movable concrete spreader?

- Check the insulation resistance of the circuit of the motor, the grounding of the electrical equipment, metal case and metal structure

- Q: How to distinguish tower type distributor and general distributor?

- The steel spreader and the circular pipe distributing machine of the general distributing machine are all simple structures,

- Q: What are the benefits of concrete handling machines?

- The construction area of the crane pipe can not be reached, and the concrete distributor can be used instead

Send your message to us

Manual Frame Struction Concrete Placing Boom

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords