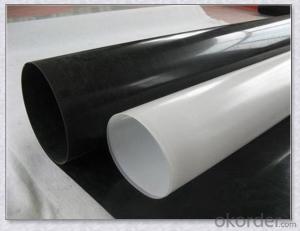

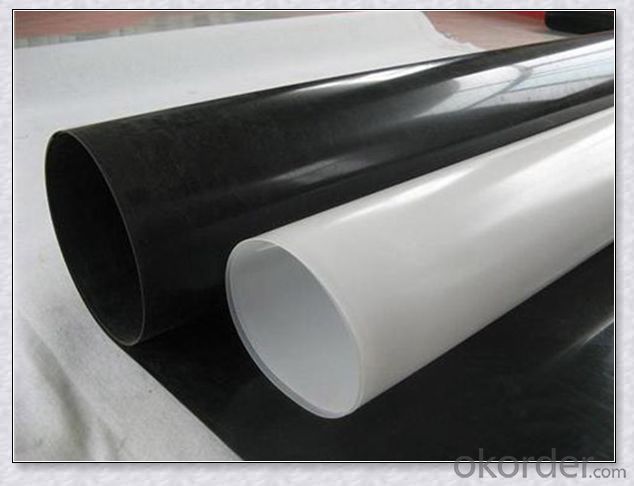

Manta Geotextil Para Jardim HDPE Roll Geomembrane for Aquaponics Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geomembrane

Composite Geomembrane with impermeable plastic film as a substrate, and non-woven geotextile composite made of impermeable material, which depends on the seepage properties of a impermeable plastic film performance. Is a kind of polymer chemistry flexible material, the proportion of small, extensible stronger ability to adapt to high deformation. Corrosion resistance, low temperature, frost good performance. Have better resistance to erosion, are not afraid of acid, alkali and salt erosion.

Applicable to river dams, tunnels, drainage bank seepage, metallurgy and chemical industry pollution prevention, construction, transportation, environmental protection works.

PE film thickness: 0.2mm-0.8mm Product Specifications: Width 4m-6m, weight 300g/m2-2400g/m2.

Product categories: a cloth one membrane, two cloth one membrane.

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help in stabilizing railroad tracks?

- Geotextiles help in stabilizing railroad tracks by providing reinforcement and separation between the track components and the underlying soil. They prevent the mixing of soil particles with the track ballast, which can lead to track settlement and degradation. Geotextiles also distribute the load of passing trains more evenly, reducing the risk of track deformation and improving overall stability.

- Q: What are the specifications for geotextiles in coastal protection projects?

- The specifications for geotextiles in coastal protection projects typically include factors such as the material type, strength, permeability, and durability. The geotextiles used should be made of high-quality synthetic fibers, such as polypropylene or polyester, to withstand the harsh coastal environment. They should have sufficient tensile strength to resist erosion and provide stability to the project. The permeability of the geotextiles is crucial to facilitate proper drainage and prevent the buildup of water pressure. Additionally, the geotextiles should have excellent resistance to UV degradation and chemical exposure to ensure long-term performance in coastal conditions.

- Q: What are the geotextiles for concrete health

- Is non-woven material

- Q: How do geotextiles prevent soil erosion?

- Geotextiles prevent soil erosion by acting as a barrier that stabilizes the soil, allowing water to pass through while preventing the movement of soil particles. They provide reinforcement to the soil, reducing the erosive forces of wind and water, and promoting vegetation growth by retaining moisture and nutrients in the soil.

- Q: What are the key considerations for geotextile installation in high wind areas?

- The key considerations for geotextile installation in high wind areas include selecting a high-strength geotextile material, ensuring proper anchoring and securing methods, evaluating the site's wind load potential, and implementing effective quality control measures to ensure the installation's durability and long-term performance.

- Q: Alteration of highway seepage control geotextile is generally placed in what position

- Apply to the grassroots level of water defense, the use of embedded, covered with thickness should not be less than 30CM, soil to be solid, to avoid uneven subsidence, cracks. Lap width should be greater than 15CM.

- Q: What are the key considerations for geotextile installation in areas with high seismic activity?

- The key considerations for geotextile installation in areas with high seismic activity include selecting a geotextile material that can withstand strong ground shaking, ensuring proper anchoring and securing of the geotextile to prevent displacement during seismic events, evaluating the potential for liquefaction and designing appropriate drainage systems to mitigate its effects, conducting thorough site investigations to understand the soil conditions and potential for ground movement, and regularly monitoring and inspecting the geotextile installation for any signs of damage or failure due to seismic activity.

- Q: Now geotextile price quota how?

- 2017 geotextile price cheaper than last year, the current price of raw materials is relatively stable production. Geotextile classification of many, you ask more general, so no way to give you a detailed offer. Different technical requirements are uneven prices, but the overall price has come down, and is now the lowest price since 2017.

- Q: What is the representative batch of geotextile?

- Geotextile batch is 2000 square meters.

- Q: Filament non-woven geotextile, geomembrane, how much need to use third-party testing?

- This depends on the party and the supervision requirements, and generally 1-2 million square a test batch, I am specializing in the production of geotechnical materials

Send your message to us

Manta Geotextil Para Jardim HDPE Roll Geomembrane for Aquaponics Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords