Manhole Cover Ductile Cast Iron GGG40 C250 Bitumen Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Cast Iron Manhole Cover Description :

Description:

Code | Clear Opening(mm) | Over Base(mm) | Depth(mm) | Class |

202500 | 200 | 230 | 33 | A15 |

202501 | 200 | 230 | 33 | B125 |

202502 | 300 | 330 | 40 | A15 |

202503 | 300 | 330 | 40 | B125 |

202504 | 400 | 440 | 45 | A15 |

202505 | 400 | 440 | 45 | B125 |

202506 | 400 | 440 | 45 | C250 |

202507 | 400 | 440 | 45 | D400 |

202508 | 550 | 590 | 60 | A15 |

202509 | 550 | 590 | 60 | B125 |

202510 | 550 | 590 | 60 | C250 |

202511 | 550 | 590 | 60 | D400 |

202512 | 700 | 740 | 60 | A15 |

202513 | 700 | 740 | 60 | B125 |

202514 | 700 | 740 | 75 | C250 |

202515 | 700 | 740 | 95 | D400 |

202516 | 760 | 800 | 75 | A15 |

202517 | 760 | 800 | 75 | B125 |

202518 | 760 | 800 | 75 | C250 |

202519 | 760 | 800 | 110 | D400 |

202520 | 800 | 840 | 85 | A15 |

202521 | 800 | 840 | 85 | B125 |

202522 | 800 | 840 | 85 | C250 |

202523 | 800 | 840 | 85 | D400 |

202524 | 900 | 940 | 100 | A15 |

202525 | 900 | 940 | 100 | B125 |

202526 | 900 | 940 | 100 | C250 |

202527 | 900 | 940 | 100 | D400 |

202528 | 1000 | 1040 | 100 | A15 |

202529 | 1000 | 1040 | 100 | B125 |

202530 | 1000 | 1040 | 100 | C250 |

202531 | 1000 | 1040 | 100 | D400 |

202532 | 1325 | 1365 | 100 | A15 |

202533 | 1325 | 1365 | 100 | B125 |

202534 | 1325 | 1365 | 100 | C250 |

2.Main Features of the Ductile Iron Manhole Cover:

Strong resistance of acid, alkali, weathering, anti corrosion of water, dust, manhole covers used for gas are well sealed which prevent poisonous gas leaking.

Temperature tolerance is at the range of -40°C-200°C.

FRP manhole covers allow customers’ innovative design, logo, or etc. we have our own design team who can also offer design work for customers.

The cover is not sprayed in surface but painted in whole material so that the color can keep no fading.The products are made anti-noises, which is popular to residential areas.

Applications:

Manholes allow access to underground pipes, cables, meters and facilities.

BS EN124 Standard:

A15: Area which can only be used by pedestrians and pedal cyclists.

B125: Footways, pedestrian areas and comparable parks or car parking decks.

C250: For gully tops installed in the area of curbside channels of roads.

D400: Carriage ways of roads(including pedestrian streets), hard shoulder and parking areas, for all types of road vehicles.

E600: Areas of imposing high wheel loads, e.g. dock and aircraft pavements

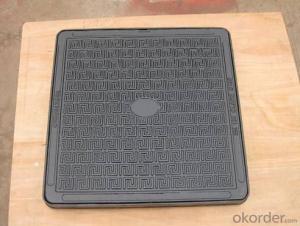

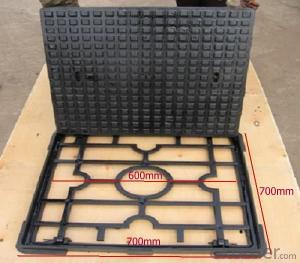

3.Manhole Cover Images:

4.Manhole Cover Specifications:

1) High load rating and strength

2) Against theft and safety options

3)Durable service life.

4)Free design

1) Various manhole cover strictly conform to standard and free from sand holes, blow holes, distortion or any other defects

2) Processes:

a) Automatic machine lines

b) Moulding boards

c) Green sand with hand moulding

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. Can I fit a square manhole cover into a round chamber?

A. Yes, there are a select few manhole covers which are square-to-round, meaning they will fit square or round chambers.

Q. I have a heavy traffic manhole cover but it has been broken by a forklift, why?

A. Forklifts have solid wheels which apply pressure differently to standard pneumatics and therefore covers must be specially adapted to suit this.

Q. I’ve measured my clear opening size but none of your covers match it, can you offer anything?

A. It’s likely that your cover is quite old and in imperial measurements which are no longer manufactured. However, we can offer bespoke solutions with manhole covers made to the specification you require.

Q. The project I’m working on requires a manhole cover with a quality finish, what’s available?

A. Naturally, galvanised steel of black polypropylene aren’t always ideal, and so we offer brass or stainless steel edging, as well as complete stainless steel covers.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Cast iron has not been done, if it is iron, then in the spray before going through strict pretreatment, the surface can not have a little oil dust

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Now resin sand, coated sand and other processes are also very good surface.

- Q: What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

- Q: What are the general technical requirements for casting parts?

- Satisfy appearance quality (appearance defect, quality change, size deviation)Intrinsic quality (composition, properties, internal organization)Service performance (abrasion resistance, corrosion resistance, heat resistance, pressure resistance)

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

Send your message to us

Manhole Cover Ductile Cast Iron GGG40 C250 Bitumen Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords