Magnesium Plate Hardox400 Plate Printing Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Magnesium Plate Hardox400 Plate Printing Plate:

- Aerospace, defense and satellite applications where weight reduction is critical

- Electronic components where shock absorbing qualities are crucial

- Automotive/Motor sports applications where weight reduction and strength are required

- Mechanical vibration shakers for test fixtures

2.Advantage of Magnesium Plate Hardox400 Plate Printing Plate:

- Magnesium is the lightest industrial metal in the world

- One third lighter than aluminum

- Magnesium is as strong as aluminum

- Magnesium is shock absorbing and dampens vibrations

- Magnesium is very machinable

3.Mechanical Property of Magnesium Plate Hardox400 Plate Printing Plate:

Positive CTP Plates | |

1. ISO9001:2000 | |

2. Long press time | |

3. High quality | |

4. For commercial printing and news paper printing | |

Surface treatment | Use the fine aluminum substrate with electro chemically graining, anodized oxidization, and hydrophilic treatment |

Spectral sensitivity | 800-850nm,Max:830nm |

Exposure quantity | 120-150mj/cm2 |

Resolution Power | 1-99%@450lpi |

Run length | Before baking: 100,000+ |

After baking: 300,000+ | |

UV ink applicability | Can be used after baking |

Baking condition | 230-250℃,5-8min(With recommended CTP baking solution) |

Size | Maximum size of short side: 1450mm |

Diagonal cutting tolerances: ≤0.5mm | |

Storing condition | Away from light and heat,keep in dry and cool place |

The recommended condition | Temp: 5-30 ℃,RH:40-80% |

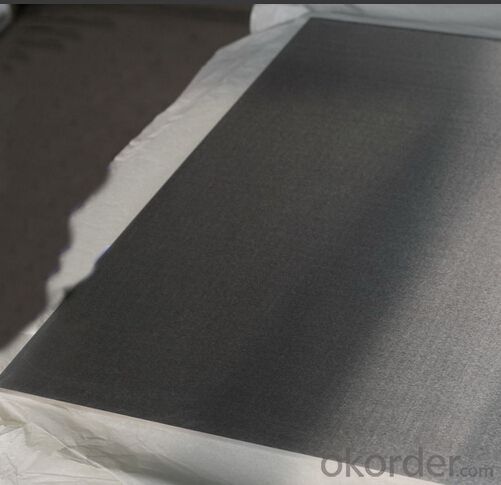

4.Picture of Magnesium Plate Hardox400 Plate Printing Plate:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Y represents the metallurgical (Yejin) Department standard. W stands for universal (Wanneng) alloy

- Ha ha, I'm good at that!HC is the sign of the attractive magnetic force of the alloy, and HRA is the sign of hardness. COM is the cobalt magnetic mark of the alloy. D is the density of the alloy. The general quality certificate of the alloy product will have three indexes above

- Q: What's the use of recycling cemented carbide?

- Refined tungsten, northern recovery mostly shipped to Hebei, Xingtai.

- Q: What are the differences between the two grades of carbide, YT15 and YT5?

- YT15 is compared to YT5. The former has high hardness, great brittleness and good wear resistance. The latter is low in hardness, tough in toughness and poor in wear resistance. YT5 is often used for roughing or machining, impact cutting, and YT15 is usually semi finishing and finishing.

- Q: What is the difference between them?From hardness, abrasion resistance analysis!

- Artificial diamond is in high temperature (about 2000 DEG C) and high pressure (5 ~ 9GPa) and the metal catalyst under the condition of the graphite into diamond (PCD) tool. The tool of non-ferrous metals and non-metallic materials processing the alloy, ceramics, glass, wood, graphite and other best. With a cutting speed of up to 5000m/min PCD cutting tool Aluminum Alloy above. High speed steel alloy steel is a kind of complicated, containing tungsten, molybdenum, chromium, vanadium and cobalt carbide forming elements about alloy element.

- Q: How to distinguish the authenticity of Zhuzhou diamond brand cemented carbide blade?

- In fact, now only look at the packaging has been unable to identify, because now the copycat alloy packaging has really not with what two things, want to know after the authenticity can be used, you can try to buy a small amount of alloy, the quality of clearance to buy a lot, you can go to the station to find the Alibaba China @ Rui Sen # trade. Easy% Co., reputation has been good, but sales of hard alloy Zhuzhou diamond factory, there are quality problems can return shipping.

- Q: What kinds of carbides are there? How should we choose in production?

- Tungsten cobalt carbide (YG): suitable for brittle materials such as cast iron;Tungsten cobalt titanium carbide (YT): it is suitable for processing plastic materials, such as steel;General purpose cemented carbide (YW): commonly used for processing stainless steel, heat-resistant steel, high manganese steel and other difficult to process materials.

- Q: What cemented carbide does 2gr13 use?

- 2Cr13 martensitic stainless steel can be processed by hard alloy YW2, carbide YW2 suitable for heat-resistant steel, high manganese steel, stainless steel and advanced alloy steel and other special difficult to processing steel finishing, semi finishing.

- Q: What about cemented carbide produced in Zhuzhou? What brand is good?

- Is good at home, as for the brand well of course is diamond, refined into a brand is also good, there are fine into hard alloy sales company, previously entered a large red facade, product is very much, the Diamond Road No. 24-5, hope to help to you.

- Q: What is the base material of carbide saw blade?

- Carbide saw blades include the kinds of alloy cutters, matrix materials, diameter, tooth number, thickness, tooth shape, angle, aperture and so on. These parameters determine the machining ability and cutting performance of saw blades. In selecting the saw blade, it is necessary to select the saw blade according to the kind, thickness, sawing speed, cutting direction, feeding speed and width of saw.

- Q: Model of grinding carbide wheel sheet

- Go online and check it outCould you show me a picture of the gold foil?

Send your message to us

Magnesium Plate Hardox400 Plate Printing Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords