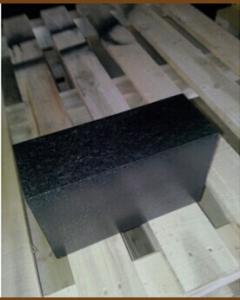

Magnesia Chrome Brick Refractories

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Magnesia chromite brick Specifications

1.High refractoriness2000,

2.excellent anti-oxidation,

3.high strength

4.perfect thermal Stability;

Magnesia chromite brick Application:

1. Used for the roof to all kinds of steelmaking furnace ;

2. RH, VOD, AOD, and other refining installations;

3. Building industry, glass furnace, cement rotary kiln etc.

Magnesia chromite brick Features:

1,Outstanding ability to form stable protective coating

2,High flexibility

3,High refractoriness

4,Low thermal conductivity

Sort | Magnesia-Chrome Brick | ||||||||

Brand Specification | QMGe 8A | QMGe 8B | QMGu 12A | QMGe 12B | QMGe I6A | QMGe 16B | QMGe 20A | QMGe 20B | QMGe 22 |

MgO %≥ | 65 | 60 | 60 | 55 | 50 | 45 | 45 | 40 | 46 |

Cr2O3 %≥ | 8 | 8 | 12 | 12 | 16 | 16 | 20 | 20 | 22 |

Apparent Porosity%≤ | 20 | 20 | 20 | 20 | 20 | 23 | 20 | 23 | 20 |

Cold Crushing Strength Mpa ≥ | 35 | 30 | 35 | 30 | 35 | 30 | 35 | 30 | 35 |

Refractoriness Under Load C ≥ | 1620 | 1550 | 1620 | 1580 | 1620 | ||||

- Q: What are the differences between magnesium chrome bricks, such as direct bonding, re bonding, semi bonding, CO sintering and chemical bonding? Hope expert advice..

- The process of firing magnesia chrome bricks is roughly the same as that of magnesia bricks. In order to eliminate the brick during firing, due to MgO and Cr2O3, Al2O3

- Q: Process for producing magnesia chrome brick

- The oxide of iron reacts to produce a loose effect caused by the expansion of the spinel. Also, the magnesia chrome brick can be made from the synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees.

- Q: How much is magnesium chrome brick a ton?

- Magnesium chrome bricks according to physical and chemical indicators in order to know the specific price, the production of magnesia chrome brick place a lot

- Q: How many kinds of refractory bricks are there?

- Magnesia chrome brick: Hang kiln, used for firing zone, the disadvantage is the poor thermal shock resistance, plus six Cr price is highly toxic, the production and use of the national magnesia chrome brick is gradually reduced, the brick production unit as soon as possible to find alternatives.

- Q: Magnesium chrome brick price?

- Dashiqiao magnesium brick factory of China Building Materials Academy is a joint stock company invested, constructed and managed by China Building Materials Academy.The plant was built in 1992, officially put into operation in 1993, covers an area of 89 thousand square meters, has a long 118 meters, an annual output of 30 thousand tons of high temperature tunnel kiln production line. The group has 1200 employees, 6 senior engineers, more than 20 engineers and technicians, and has strong technical force. Group's total assets of 5.5 million, with an annual output value of 600 million. Profit and tax 65 million yuan.

- Q: What is a half combination of magnesia chrome bricks?

- Direct binding for magnesium magnesium rock stone or periclase spinel crystals, silicate phases were isolated in the grain asked. Half combined with thermal shock resistance than magnesia chrome brick direct bonded magnesia chrome brick, and about half combined with the characteristics of magnesia chrome brick, some physical and chemical indicators. I don't understand, I know there is a production of magnesia chrome brick factory technicians understand this, is known as gold refractory material factory.

- Q: With different capacitance magnesia brick brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius. It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: What is the difference between magnesia chrome brick and direct bonded magnesia chrome brick?

- The performance of direct bonding magnesia chrome brick is better than that of common magnesia chrome brick.

- Q: What are the main raw materials of magnesia chrome bricks?

- Magnesium alloys are alloys based on magnesium and other elements. Its characteristics are: small density (1.8g/cm3 magnesium alloy or so), high specific strength, high modulus of elasticity, good heat dissipation, good shock resistance, greater impact load capacity than aluminum alloy, good resistance to organic and alkaline corrosion. The main alloying elements are aluminum, zinc, manganese, cerium, thorium, and a small amount of zirconium or cadmium.

Send your message to us

Magnesia Chrome Brick Refractories

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords