Machine Length Tan BOPP Packing Tape with Water Based Acrylic OPP Adhesive Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

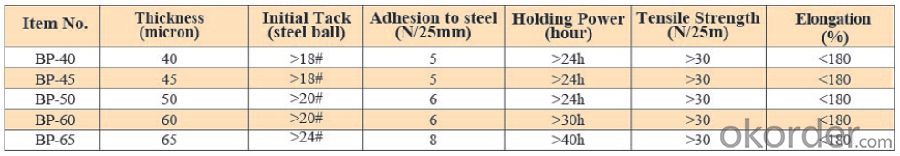

Material | BOPP film+pressure-sensitive glue |

Total Thickness | 35mic-65mic |

Width | 10/11/12/15/17/18/24/30/40/42/45/46.5/48/50/50.4/52.5/55/57/60/72mm |

Length | 30y-1000m |

Tensile | above360N/25mm |

Adhesion | above25N/25mm |

Initial Adhesive | 20-24# |

Color | Clear, white, yellow, red, blue, green, etc |

Tape Paper Core | 2.5/ 2.8/ 3/ 3.5/ 4/ 4.5/ 5/ 5.5/ 6 mm |

Jumbo Roll | 1280/980/960mmX4000m |

Available in maximum four colors print by Rotogravure Prints.(empty printing, full printing) | |

Payment | T/T(30% deposit, and the balance upon the copy of B/L ) |

L/C(30% deposit, the balance by L/C at sight ) | |

Main Market | North America/Asia/Western Europe/South America/Africa |

Certifications | CTI(TPCH,RoHs) |

MOQ | 5000rolls |

Product Discription

Applications:

Shipping, packaging, bundling, wrapping.

Ideal for sealing of cartons, merchandise, pallets

Excellent performer for both hand and machine application.

Advantages:

Characteristic:Strong adhesion,good for packing ,easy tear, low odor

Material:BOPP with high tension strength, good quality glue .

OEM Offer:The tape can be made as your request(weigh,length,microns,color,paper core etc)

Management:Has many firstlevel manager,and control the quality in the process of the production.

Glue store :Can store over 220T glue for one-time

FAQ:

1. Q:Can we order the customized logo tape?

A: Yes, we can offer the customized logo tape.

2. Q: Are you sure about the quality and length?

A: We are factory, Quality is the best advertisement. we can sure you about the quality and length.

3. Q:Can you make our logo on the paper core of the tape?

A:yes,we can help to print. and the mould cost will be $50. If the quantity is 300 cartons, then will be free of logo charge.

- Q: Is packaging tape resistant to chemicals?

- Yes, packaging tape is typically resistant to chemicals. It is designed to withstand various substances and maintain its adhesive properties, making it an effective choice for securing packages and protecting their contents.

- Q: Has anyone done a tape cut? What about profit?

- I do not know where you belong, but the overall profit is not high, if it is sold to dealers, profits are generally 2.5 to 3 cents a square or so (not deducted from the cost)

- Q: How do I prevent packaging tape from tearing during removal?

- To avoid tearing when removing packaging tape, consider the following strategies: 1. Applying heat proves effective. Utilize a hairdryer or heat gun to warm the tape. The adhesive softens, facilitating tear-free removal. Exercise caution to prevent overheating or scorching. 2. A cutting tool, such as a utility knife or scissors, can be employed when tape removal becomes challenging. Carefully cut through the tape to prevent tearing, opting for smaller, manageable sections. 3. Adopt a patient and deliberate approach. Remove the tape gradually and at a low angle, exerting gentle pressure to avoid tearing. If met with resistance, pause and attempt different angles or apply heat to loosen the adhesive. 4. If the tape proves stubborn, seek assistance from a solvent like rubbing alcohol or adhesive remover. Apply a small amount to a cloth or cotton ball and gently rub the tape to dissolve the adhesive. Test the solvent on a discreet area first to ensure it doesn't damage the surface. 5. Make an informed tape selection. Opt for high-quality packaging tape with strong adhesion and good tensile strength. Reinforced or heavy-duty tapes are less prone to tearing. By employing these techniques cautiously, you can successfully remove packaging tape without tearing it.

- Q: Can packaging tape be used for sealing plastic bags?

- Indeed, sealing plastic bags can be accomplished with the utilization of packaging tape. Designed with robust adhesive properties, packaging tape can effectively secure various items, including plastic bags. To achieve a secure seal and prevent spillage or exposure to air and moisture, the tape can be applied either along the opening or across the entire width of the bag. It is worth mentioning, though, that while packaging tape can serve the purpose, it may not be as efficient as specialized plastic bag sealing techniques like heat sealing or ziplock closures, which are specifically engineered for this particular task.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. It is designed to adhere to various surfaces, including painted surfaces, without causing damage or leaving residue when properly applied and removed. However, it is always recommended to test a small, inconspicuous area first to ensure compatibility and to handle the tape with care to avoid any potential paint or finish peeling.

- Q: What are the considerations for using packaging tape on wooden surfaces?

- There are several factors to consider when using packaging tape on wooden surfaces. Firstly, it is crucial to select the appropriate type of tape for the wood. Choose a tape specifically designed for wood or one with a gentle adhesive to prevent damage or residue. Avoid strong adhesive or duct tapes that may leave sticky residue or peel off the wood's finish. Secondly, take into account the condition of the wood. If it is old, fragile, or has cracks, extra precautions are necessary. Applying tape directly to damaged or delicate wood can cause further harm, such as stripping the varnish or causing splintering. In such cases, alternative methods should be used to secure or protect the wood. Consider the duration for which the tape will be applied. If it is temporary, most types of packaging tape are generally safe to use. However, if the tape will be left on the wood for an extended period, choose a tape that is less likely to damage or leave residue when removed. Additionally, be mindful of the climate or environment in which the wood will be situated. Extreme temperatures or humidity can affect the adhesive properties of the tape, potentially causing it to lose stickiness or damage the wood. In such cases, alternative methods may be required to secure or protect the wood. Lastly, always test a small, inconspicuous area of the wood with the tape before applying it extensively. This allows for assessment of any potential damage or residue and helps make an informed decision about using the tape on the entire wood surface. By considering these factors, one can ensure the safe use of packaging tape on wooden surfaces without causing unnecessary damage or issues.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can be used for other purposes besides packaging. It can be used for sealing envelopes, securing loose items, repairing torn paper or books, creating temporary labels, organizing cables, and many other miscellaneous tasks.

- Q: How does packaging tape perform when exposed to chemicals or solvents?

- The performance of packaging tape can vary depending on the type of tape and the chemicals or solvents it is exposed to. Generally, packaging tapes are designed to resist common household chemicals like cleaning agents, oils, and water-based solvents. These tapes are typically made from materials with excellent chemical resistance properties, such as polypropylene or PVC. As a result, they can maintain their adhesion and integrity even when exposed to moderate amounts of chemicals or solvents. However, it is important to be aware that certain aggressive chemicals or solvents, like strong acids or organic solvents, may have a negative impact on the tape's performance. These highly corrosive substances can cause the tape to degrade, lose its adhesive properties, or dissolve completely. To ensure optimal performance, it is recommended to consult the manufacturer's information on chemical resistance properties for the specific packaging tape being used. They can provide guidance on whether the tape is suitable for different types of chemicals or solvents. Additionally, conducting small-scale tests or trials to assess the tape's performance when exposed to specific chemicals or solvents before using it for critical packaging applications is advisable. In conclusion, packaging tape generally performs well when exposed to common household chemicals or solvents. However, its performance may be compromised when exposed to aggressive or corrosive substances. It is important to refer to the manufacturer's guidelines and conduct tests, if necessary, to ensure that the tape is suitable for the specific chemical or solvent it will be exposed to.

- Q: How does packaging tape perform on porous surfaces?

- Packaging tape generally does not perform well on porous surfaces. Porous surfaces such as cardboard, paper, or fabric tend to absorb the adhesive on the tape, resulting in a weak bond and reduced effectiveness. It is recommended to use alternative methods or specialized tapes specifically designed for porous surfaces to achieve better adhesion and secure packaging.

- Q: As for the title, just bought the tape cutter, but I don't know how to use it. I bought it in plastic. Used for packing express boxes. It's better to use a process chart for me to see.. Thanks。。 Or clear words can also...

- How do I fit the tape onto the sealing machine?There is no machine, or else let you have a look

Send your message to us

Machine Length Tan BOPP Packing Tape with Water Based Acrylic OPP Adhesive Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords