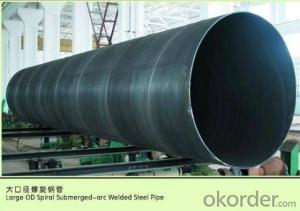

LSAW SSAW CARBON STEEL PIPE ASTM API 16’‘ 18’‘

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: What are the different methods of repairing steel pipes?

- There are several methods to repair steel pipes, including welding, flange coupling, sleeve coupling, epoxy coating, and pipe lining.

- Q: Can steel pipes be used for underground applications?

- Yes, steel pipes can be used for underground applications. They are commonly used for underground piping systems in various industries such as water, oil, and gas. The durability and strength of steel make it suitable for withstanding underground conditions, providing reliable and long-lasting performance.

- Q: How do steel pipes perform in high-temperature environments?

- Steel pipes perform well in high-temperature environments due to their excellent heat resistance and thermal conductivity. The strength and structural integrity of steel pipes remain largely unaffected, making them ideal for applications such as steam lines, boiler tubes, and high-temperature industrial processes.

- Q: How do you join two steel pipes together without welding?

- One common method to join two steel pipes together without welding is by using mechanical fittings or connectors. These fittings are designed to connect pipes securely without the need for welding. Here are a few options you can consider: 1. Threaded Fittings: Threaded fittings have male and female threads that enable you to screw them together. To join the pipes, you will need to cut the ends of the pipes to create male and female threads. Apply thread sealant to ensure a tight and leak-free connection. 2. Compression Fittings: Compression fittings consist of a nut, a compression ring, and a compression seat. These fittings are designed to create a tight seal by compressing the ring against the seat. Simply slide the compression ring and nut onto the pipe ends, and use a wrench to tighten the nut until it forms a secure connection. 3. Flange Connections: Flange connections involve using flanges, which are flat plates with bolt holes, to join the pipes. The flanges are bolted together using gaskets to create a tight seal. This method is commonly used for larger diameter pipes or in situations where frequent disassembly may be required. 4. Grooved Couplings: Grooved couplings utilize a mechanical coupling housing with two grooved ends that fit over the pipe ends. The coupling is then secured using bolts or screws, which tighten the housing around the pipe ends, creating a secure connection. This method is often used in plumbing and fire protection systems. Before deciding on a method, it is crucial to consider the specific requirements of your application, such as the pipe diameter, pressure, and temperature. Additionally, ensure that the chosen method complies with relevant industry standards and regulations to ensure a safe and reliable connection.

- Q: What is the role of steel pipes in the aerospace industry?

- Steel pipes play a crucial role in the aerospace industry as they are used in various applications such as aircraft manufacturing, engine components, and fuel systems. These pipes are known for their high strength, durability, and resistance to extreme temperatures and pressure. They provide a reliable conduit for fluids, gases, and hydraulic systems, ensuring efficient operations and safety in aircraft. Additionally, steel pipes are utilized in structural components like landing gear, frames, and support structures due to their ability to withstand heavy loads and maintain structural integrity under dynamic conditions. Overall, steel pipes are essential in the aerospace industry for their versatility and reliability in critical systems and structures.

- Q: How do steel pipes handle ground freezing and thawing?

- Steel pipes are highly resistant to the effects of ground freezing and thawing. The inherent strength and durability of steel make it an ideal material for handling these thermal cycles. When the ground freezes, steel pipes are able to withstand the expansion forces exerted by the freezing water without any significant damage. The structural integrity of steel pipes remains intact even under extreme cold conditions. During thawing, steel pipes also fare well due to their ability to contract without compromising their strength. The material's flexibility ensures that it can accommodate the contraction of the ground without causing any structural issues. Steel pipes do not crack or break when exposed to the rapid temperature changes associated with thawing. Furthermore, steel pipes have a smooth internal surface, which reduces the risk of ice formation and subsequent blockages. This is particularly important in areas with frequent freezing and thawing cycles, as it helps to maintain a consistent flow of fluids or gases through the pipes. In summary, steel pipes are an excellent choice for handling ground freezing and thawing. Their strength, durability, and ability to withstand temperature fluctuations make them a reliable and long-lasting solution in such environments.

- Q: What are the different coatings applied to steel pipes?

- There are several different coatings applied to steel pipes, including epoxy coatings, polyethylene coatings, zinc coatings (galvanization), and fusion bonded epoxy coatings. These coatings are used to protect the steel pipes from corrosion, increase their durability, and improve their performance in various environments.

- Q: What are the different types of corrosion that can affect steel pipes?

- There are several types of corrosion that can affect steel pipes, including uniform corrosion, pitting corrosion, crevice corrosion, galvanic corrosion, and stress corrosion cracking.

- Q: How are steel pipes protected against rust and corrosion?

- Steel pipes are protected against rust and corrosion through various methods such as applying protective coatings, galvanizing, and cathodic protection. These measures create a barrier between the steel surface and moisture or corrosive substances, ensuring the longevity and integrity of the pipes.

- Q: How are steel pipes used in sewage systems?

- Steel pipes are commonly used in sewage systems due to their durability and strength. They are used to transport sewage from homes, buildings, and industries to treatment plants or disposal sites. The corrosion-resistant properties of steel make it an ideal material for sewage systems, ensuring longevity and preventing leaks. Additionally, steel pipes can withstand high pressure and heavy loads, making them suitable for underground installations.

Send your message to us

LSAW SSAW CARBON STEEL PIPE ASTM API 16’‘ 18’‘

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords