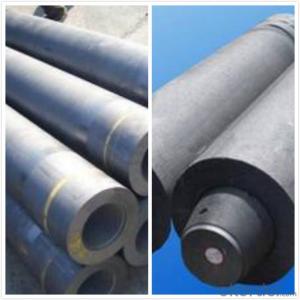

Low Specific Resistance RP, HP, and UHP Type Graphite Electrode for Steel Mill

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TECHNICAL PROPERTIES OF GRAPHITE ELECTRODE

1.Physical and chemical index

Item | Unit | RP | HP | UHP | ||||

250-400 | 450-800 | 300-400 | 450-700 | 300-400 | 450-700 | |||

Electric Resistivity | Electrode | μΩ.m | 7.5-8.6 | 7.5-8.8 | 5.5-6.8 | 5.5-7.0 | 4.6-6.0 | 4.8-6.2 |

Nipple | 4.5-5.5 | 4.0-5.0 | 3.5-4.5 | |||||

Bending Strength | Electrode | MPa | ≥8.0 | ≥11.0 | ≥11.0 | |||

Nipple | ≥15.0 | ≥16.0 | ≥18.0 | |||||

Elastic Modulus | Electrode | GPa | ≤9.0 | ≤11.0 | ≤13.0 | |||

Nipple | ≤13.0 | ≤14.0 | ≤15.0 | |||||

Bulk Density | Electrode | g/cm3 | 1.55-1.65 | 1.63-1.73 | 1.65-1.75 | |||

Nipple | 1.70-1.75 | 1.73-1.80 | 1.75-1.82 | |||||

Ash | Electrode | % | ≤0.3 | |||||

Nipple | ||||||||

CTE (100-600)℃ | Electrode | 10-6/℃ | 2.00-2.50 | 1.80-2.00 | 1.30-1.50 | |||

Nipple | 1.50-1.80 | 1.50-1.80 | 1.20-1.40 | |||||

2.Recommended current carrying capacity

Nominal Diameter (mm) | RP | HP | UHP | ||||

Current Carrying Capacity | Current Density | Current Carrying Capacity | Current Density | Current Carrying Capacity | Current Density | ||

in | mm | A | A/cm2 | A | A/cm2 | A | A/cm2 |

12 | 300 | 1000-13000 | 14-18 | 13000-174000 | 17-24 | 15000-22000 | 20-30 |

14 | 350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

16 | 400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

18 | 450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-27 |

20 | 500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

22 | 550 | 32000-40000 | 13-16 | 35000-55000 | 14-22 | 42000-64000 | 17-26 |

24 | 600 | 35000-41000 | 13-15 | 41000-61000 | 14-21 | 50000-73000 | 17-25 |

28 | 700 | 39000-48000 | 10-12 | 55000-82000 | 14-21 | 67000-99000 | 17-25 |

32 | 800 | 43000-54000 | 8-10 | / | / | / | / |

FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- The technical development of the high-speed machining center lays the foundation for improving the milling efficiency and quality of the graphite electrode, especially for the milling of the small electrode with complicated shape and thin wall. In the EDM mold processing, the graphite electrode needs to be processed by the high-speed machining center (HSM), so the demand for HSM machine tools is also increasing. But for some time, because of the technological developments in hard steel processing, it seems possible to make graphite electrodes an obsolete technology.

- Q: Why graphite can be used as conductive material?

- Lubricants can not be used in high speed, high temperature, high pressure conditions, and graphite wear-resistant materials can be at the temperature and at a high sliding speed, without lubricating oil work. Many transporting corrosive media devices are widely used, which is made of graphite material piston ring, the sealing ring and the bearing, they are running, without adding lubricating oil, graphite and many metal processing when good lubricant.

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- During electrolysis, cations move toward the cathode, electrons are reduced at the cathode, anions are moved toward the anode, electrons are lost at the anode and oxidized. And you use both sides of the graphite rod, is inert electrode, so there will be no copper ions added to the solution, copper in the solution of consumption, the color of natural shallow.

- Q: Which department in the steel plant needs graphite in large quantities?

- For steel and iron alloys, graphite electrodes are used, when powerful currents pass through electrodes into the melting zone of the electric furnace to produce an arcThe electric energy is converted into heat energy, and the temperature is increased to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, the electrolytic goldWhen the magnesium, aluminium and sodium are used, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace for carborundum is also made of graphite electrode as the burnerConductive material.

- Q: Why should graphite paper be placed between the heater and the graphite electrode?

- Determine the thickness of the graphite bowl, the thickness of the graphite bowl is generally 3 mm -6 mm, three, determine the diameter of the heater, according to the diameter of the crucible and the thickness of the graphite bowl, calculate the inner diameter of the heater. The gap in the quartz crucible diameter phi = +2 times is +2 times the wall thickness of stone bowl bowl and graphite heater if the graphite bowl wall thickness is a, graphite bowl gap and heater for B (b=5 mm), phi = Phi Phi +2a+2b= within the outer crucible outer crucible +2 (a+b) four, to determine the effective heater the height after practice, the effective length of the quartz crucible heater is high 1.6 to 1.8 times.

- Q: Graphite powder produced by graphite electrode and what we usually call graphite is a kind of thing?

- In the electric arc furnace, the electric energy is released in the form of an arc, and the conductor is heated and melted. According to the quality index, the conductor can be divided into ordinary power, high power and ultra high power.

- Q: After vacuum melting of quartz crucible, there are three graphite electrode rods. What's the adjustment?

- The shorter one is the farther away from the other, and the shorter one is the shorter one

- Q: Excuse me, why does the graphite electrode flake when electrolyzed salt water is used?

- For example, according to connection of the electrode, which can be divided into two types of unipolar and bipolar type electrolyzer (see photo). The electrode is connected with the DC power supply parallel polarity monopolar electrolyzer, electrodes on both sides of the same, at the same time as anode or cathode. At the same time as the positive and negative electrode bipolar type electrolyzer ends respectively with DC power supply connected, as anode or cathode. The current through the electrode through the electrolysis cell in series, each side of the intermediate electrode as the anode, the other side is the cathode, so it has a bipolar electrode. When the total area at the same time, the current bipolar type electrolyzer is small, high voltage DC power supply, the required investment ratio monopolar, bipolar type filter press used. The general structure, more compact. But easy to leakage and short circuit, slot structure and operation management is more complex than the monopolar type. The monopolar electrolyzer section is generally rectangular or square, cylindrical covers a large, empty The utilization rate is low and the adoption rate is less

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- The actual electrolysis of hydrogen sulfide, which produces no black, or impurities that are absorbed by the anode, is graphite, because the dots explain the loose particles that are absorbed on the surface

- Q: What does graphite electrode GSK mean?

- Graphite board material is GSK, GSK refers to model specifications

Send your message to us

Low Specific Resistance RP, HP, and UHP Type Graphite Electrode for Steel Mill

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords