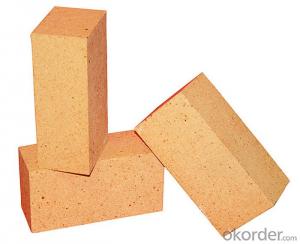

Low Creep Checker Bricks Hot Blast Furnace Low Creep High Alumina Andalusite Checker Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM Group is listed No.187 in on Fortune Global 500, 2020.

Refractory is one of the main products of the group. At the same time, under the globalization strategy, CNBM International is the exporter, logistic and local service supplier.

13 Refractory plants locate in 9 different cities

15 professor level senior engineers,239 engineers,5 senior experts committed Iron & Steel industry

Annual production capacity is over 400,000 tons.

Product Name: Low Creep High Alumina Andalusite Checker Brick for HBF.

Features:

High thermal shock resistance

Low creep

Technical Data Sheet for DRL-145

ITEMS | UNIT | VALUE |

Al2O3 | % | ≥65 |

Fe2O3 | % | ≤1.5 |

TiO2 | % | ≤0.6 |

Bulk Density | g/cm3 | ≥2.5 |

Apparent Porosity | % | ≤23 |

CCS | Mpa | ≥55 |

0.2 Mpa RUL , 0.2MPa | ℃ | ≥1550 |

Refractoriness | ℃ | ≥1790 |

0.2 Mpa Creep Rate 1450℃×(0~50)h , 0.2MPa 1450℃×(0~50)h | % | ≤0.8 |

Thermal Shock Resistance 1100℃, water ,1100℃ | cycle | ≥30 |

Product Photos of 7-hole Low Creep Checker Bricks

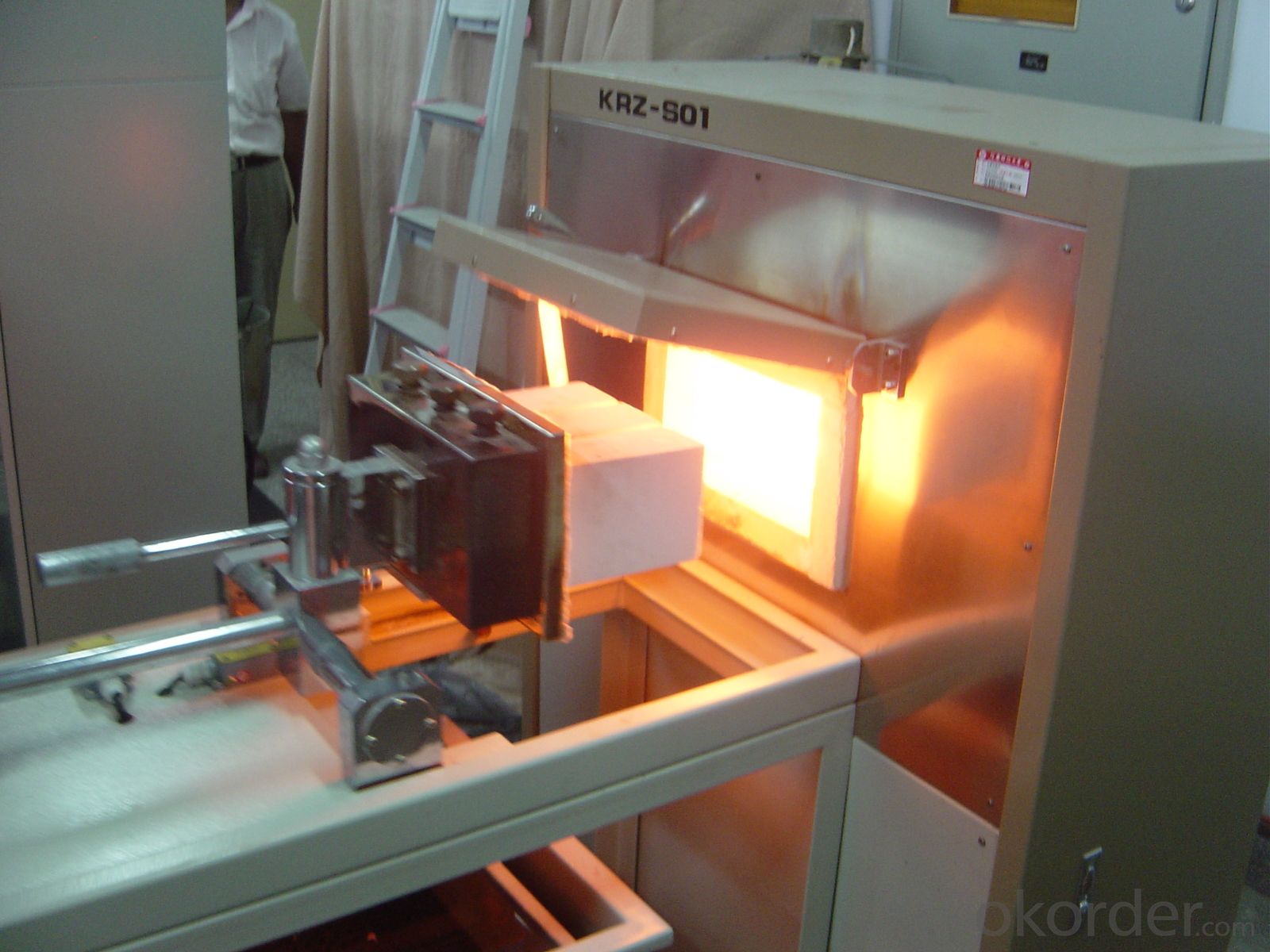

Our workshop

- Q: What is fireproof concrete?

- According to the different properties of fire resisting and heat resisting concrete, they can be divided into silicate, aluminate, phosphate, sulfate, chloride, sol and organic substance, fireproof and heat-resisting concrete, etc.. The following are mainly used silicate, aluminate, phosphate, sulfate fire, heat-resistant concrete.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: How much is one ton of high alumina refractory brick?

- Three high aluminum refractory brick Zhengzhou Kuwait is generally around 800. 32 years of experience, good.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: How are the high alumina bricks fired?

- According to the quality requirements of different grades of high alumina brick, choose different grades of bauxite raw materials, it is conducive to rational use, fine materials, fine distribution, as far as possible not to use mixed grade severe raw materials. The quality of the clinker depends on the calcination temperature, calcination temperature, sintering temperature should be generally reached or slightly higher than that of alumina clinker sintering, to ensure the full and possible high volume density, and the two secondary Mullitization and sintering shrinkage effect in calcination process. Lightweight high alumina brick, also known as high aluminum insulation brick (high-aluminium heat insulating brick). A lightweight refractory consisting of mullite and glass phases or corundum in excess of 48%. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: What are the specifications for bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: How to distinguish the good or bad of the high aluminum brick?

- In the procurement of high alumina brick, the first color, high quality aluminum brick, brick surface smooth, yellow color pale, four sides equal, no broken angle, no cracks.

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

- Q: Is glass wool inorganic thermal insulation material?

- Yes, glass wool belongs to one kind of glass fiber. It is a kind of man-made inorganic fiber. Therefore, in the field of thermal insulation materials classified as inorganic insulation materials.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The physical and chemical properties of refractory materials used in rotary kiln are as follows: physical and chemical properties of refractory materials used in rotary kilnMaterial name: high temperature compressive strength (MPa), softening temperature (DEG C), thermal shock resistance (1100 DEG C, cold water), sub volume density (g/cm3)Magnesia spinel brick is greater than or equal to 50 is greater than or equal to 1700 = 12 = 2.95High alumina brick is greater than or equal to 75 = 1520 = 8 = 2.57High aluminum bricks more than 50 = 1700 = 12 = 1The clay brick is greater than or equal to 30 = 1400 = 12 = 2.30

Send your message to us

Low Creep Checker Bricks Hot Blast Furnace Low Creep High Alumina Andalusite Checker Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords