2x4 Linyi Construction Timber PP Plastic Plywood for Concrete Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Plywoods | Place of Origin: | Shandong China (Mainland) | Brand Name: | FANGYUAN brand |

Model Number: | plastic coated plywood | Usage: | Outdoor | Grade: | First-Class |

Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | 15-Ply Boards |

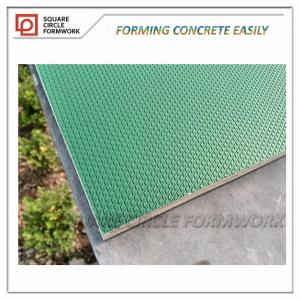

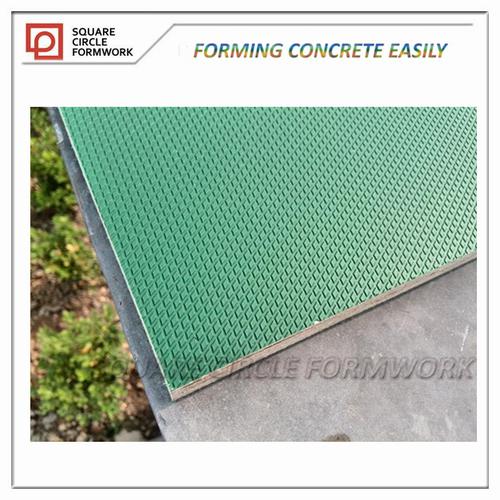

Surface: | PP plastic | Based board: | poplar, birch | Glue: | WBP phenolic, 72h water boiling |

Reusability: | 30 times at least | Dismantling: | no release agent | Cleaning: | easy cleaning by water, no oil treatment |

Concrete finish: | nice finish without re-work again | Color: | green, red, blue, grey, on request |

Packaging & Delivery

Packaging Detail: | standard seaworthy export package, inner packing by waterproof plastic bag and hard corrugated paper, outside packing by plywood pallet and fastened by steel belts |

Delivery Detail: | within 20 days from the date we receive the deposit |

Specifications

plastic coated plywood

1.coating by PP plastic

2.WBP phenolic

3.reusable 30 times at least

4.nice concrete finish

Product Description

Structure

Specification

Advantages

Technical test

Handling instruction

Comparasion

Packaging & Shipping

Our Services

1. Pengcheng Group have been specializing production andexport plywood for over 20 years, supplying highquality construction plywood for oversea customers.

2. Independent laboratary test the essential technicaldates of construction plywood, such as

bonding strength, moisture, bendingstrength, and bending modules of elasticity.

3. The CE and ISO9001 certifications are available.

4. well-built operation process for inspection, clearancecustoms, necessay export documents,

and logistics.

Company Information

Production capability

Company profile

FAQ

1. Are you a manufacturer or trader ?

Pengcheng Group have 3 factories and 1trading company, specializing in direct-sales.

2. How do you guarantee the quality of product ?

Firstly, Pengcheng Group have independentQC department to check and test every

production process. Meanwhile, we havebuilt files to resource the product when it meets

problems.

Secondly, our product have been tested byNational Building Materials Testing Center and

European Laboratory.

Finally, we supply free samples for test.

3. How is your price ?

Pengcheng Group is located in Linyicity, the largest plywood base in China. We have built

good supply chain of raw materials.Besides, the strict management system can control the

cost for every production and sales.

4. How do we build a long-standing business ?

Firstly, we supply good product withreasonable price.

Secondly, when we have reached anagreement for long-standing business, the best payment

terms are considerate.

Thirdly,expanding the sales chanels by cooperation, such as attending the internationalfairs,

building factory in your country.

Finally, invest the new project and buildthe international joint-venture company.

- Q: National standards for decorative veneer veneer plywood performance requirements

- China is the recommended standard GB / T 15104-94 "decorative veneer veneer board", the vast majority of enterprises to implement the implementation of this standard

- Q: Selection of plywood in plywood production

- Natural wood veneer is made of precious natural wood, veneer or cut by the processing of veneer veneer

- Q: How do you choose plywood in plywood production?

- but the overall furniture, wood is made of other wood, and now the store will be the furniture as "

- Q: What is the amount of construction works used for this plywood?

- The second type of plywood is water resistant plywood, can be immersed in cold water and short time hot water immersion;

- Q: Hard fiber board is also a density board

- the same texture direction. Adjacent two-layer veneer grain direction should be the same. The plywood should be the same tree.

- Q: Material for the plywood defects which

- false heartwood heartwood sound wood center part of the color is different from the normal wood, often dark brown or reddish-brown, usually its density and hardness are relatively large.

- Q: What are the advantages and disadvantages of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: Decorative veneer veneer plywood features

- Decorative veneer veneer plywood is made of natural wood decorative veneer affixed to the plywood made of wood-based panels.

- Q: One of the commonly used materials for furniture is a wood-based panel

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: Solid wood and plywood which is better?

- in addition, also need to consider its ground load capacity and use In the geothermal thermal conductivity; and the general splint or plywood in this consideration is not much.

Send your message to us

2x4 Linyi Construction Timber PP Plastic Plywood for Concrete Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords