Lightweight Composite Material Translucent Resin Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

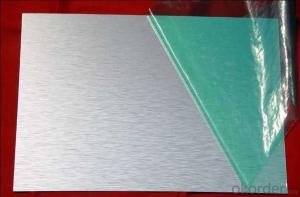

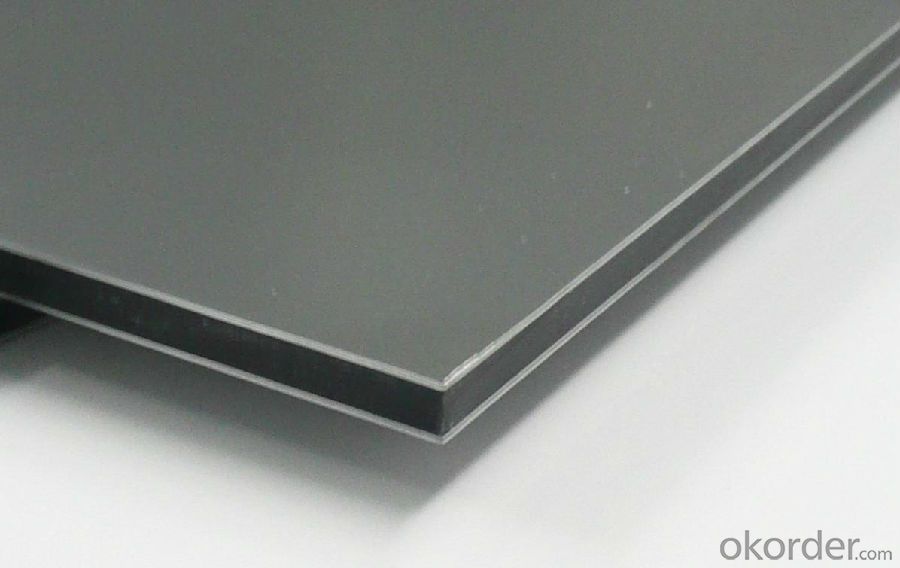

Lightweight Composite Material Translucent Resin Panel

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: Aluminum-plastic plate what material can do the door

- And the door is the most common the most popular material or aluminum-plastic plate or called aluminum composite panels.

- Q: What is the difference between stretching aluminum and hot-rolled aluminum? What is the concept of stretching aluminum?

- Aluminum in the course of the use of a variety of processing methods: which are stretching, bending, stamping, cutting, etc. Tensile aluminum generally can not be too hard, too hard will pull the explosion, so the elongation of aluminum and anti- Tensile strength and so on according to the height of the drawing and the drawing method will have different requirements.Calculation and hot-rolled plate can be used for stretching, but the effect of casting plate is not ideal, so usually the stretch plate are generally Hot rolled plate.

- Q: What are the chemical composition of aluminum veneer for building decoration

- YS / T 429.2-2000 Aluminum curtain wall Fluorocarbon painting Aluminum veneer

- Q: Is the aluminum composite board the same as the aluminum composite panel?

- Aluminum composite core layer of mineral wool there are other environmentally friendly or special core material

- Q: What can aluminum-plastic plates do! Where to decorate! how to use!

- Aluminum-plastic composite board itself has a unique performance, determines its wide range of uses:

- Q: What are the hazards of aluminum-plastic panels?

- Cadmium (Cd) affects the renal cortex, the heart, and the blood vessels that pass to the brain

- Q: Outside the door on the head of the aluminum-plastic plate signs on the word with what material?

- Are generally so after the installation of aluminum-plastic plate, and then paste words, but if you use an aluminum-plastic plate without seams, you can first paste the word.

- Q: The ceiling is the singing of the aluminum plate with vibrating sound how to do it

- If invalid, it is recommended to replace the thickness of the aluminum plate

- Q: 8 # of the aluminum-plastic plate unit price,

- If the price should be 180-240 yuan / square it

- Q: What is the chemical chemistry of the synthetic plastic of the aluminum-plastic plate?

- The specific operation is: the aluminum plate into the pot, and then add caustic soda, the water burned to about 60 ℃, to separate the aluminum-plastic plate, the aluminum plate separated into aluminum and plastic plate. This kind of plastic can be recycled into black particles

Send your message to us

Lightweight Composite Material Translucent Resin Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords