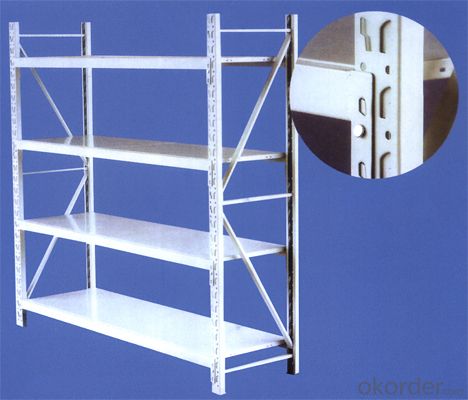

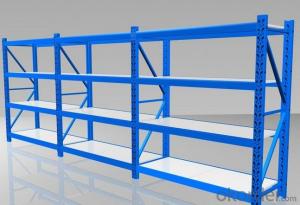

Light Duty Pallet Racking System for Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

It' s light duty racking system, used for light weight goods storage. Light duty racking system has good quality and is easy for installation. The production adopts advanced roll forming technology and guarantee good quality and high precision. Good material ensure long usage life.

Feature:

· Light duty

· Easy operation

· Convenient storage

Images:

Specifications:

Size | 1200 *W400 * 2000mm |

Loading capacity | 100kg |

color | design |

FAQ:

What is light duty pallet racking system ?

P It's easy for installation for users. allet racking system is used for light weight goods.

How is quality guaranteed?

The finished product into market are all guaranteed for users

How about the project installation?

It's easy for installation for users.

- Q: What are the key functions of warehouse management logistics informatization construction?

- In the warehouse management system, customer first is the initial inventory management (initial information collection), when the inventory is automatically increased after receipt when purchasing, sales, inventory system automatically reduced, and parity did not affect changes in the allocation of inventory, so inventory only through the inbound or outbound change or not change and, the administrator can query specific types of inventory. --- warehouse management, EBIG logistics, warehousing management system (WMS)

- Q: What are the logistics facilities and equipment in the supermarket?

- Boutique shelves, display rack, rack, titanium alloy, titanium alloy, Variety shelves, racks, steel rack, storage rack, display rack, CD rack, Variety shelves, storage shelves, sample rack, display cabinets, cabinet boutique, boutique shelves.

- Q: What are the commonly used automation equipment in warehouse logistics?

- Handheld scanning terminal, etc.. These generally need to work with standardized logistics packaging, such as shelves, materials, boxes, etc..

- Q: How to classify logistics facilities and equipment is more reasonable and scientific

- Logistics infrastructure mainly includes warehousing, carrying facilities, and computing and information communication equipment.Since human society has surplus production, there is storage, and warehouses are facilities for storing materials. In accordance with different angles, features and signs, the warehouse has its own warehouses, warehouses, public warehouses, bonded warehouses and bonded goods. Warehousing facilities play an important role in the whole logistics process:(1) the function of material storage. Any warehouse has a certain space to accommodate materials. The modern warehouse is not only a place for placing goods, but also a variety of facilities, with moderate storage and maintenance functions.(2) regulating the supply and demand of materials. There is a wide range of linkages between supply and demand as well as considerable complexity. When the supply and demand are unbalanced, the storage of the warehouse can act as a "reservoir" type.(3) regulating the function of material transportation. Transport capacity varies greatly because of the different means of transportation. The transportation contradiction caused by the difference of transportation capacity can be solved by the storage of materials, which is the function of material storage, regulation and transportation.(4) the function of material distribution. In modern logistics, warehouses in developed countries have been changed from original storage to distribution centers. That is to say to warehouse homework material sorting, matching, processing and circulation, in the new requirements, the warehouse has material distribution function.(5) the function of material saving. The role of material saving is indirectly manifested. Because people's production surplus is stored for a certain period of time without waste.

- Q: What are the common logistics equipment?

- According to the special functions of the equipment, it can be divided into transportation equipment, storage and storage equipment, loading and unloading equipment, circulation processing equipment, packaging equipment, information processing equipment, etc..

- Q: What role does warehousing play in logistics?

- Warehousing activities, or storage of the basic functions include items of import, inventory, sorting, packaging, distribution and information processing six, among them, the goods out of storage in the database and storage management can be said to be the most basic activities, is the basic of traditional storage, but the management means and management improved; sorting and packaging items, the past is there, but now more widespread, more in-depth, more sophisticated, and even have the goods out of storage and storage management combination, together constitute the basic skills of modern warehouse; the "distribution" as warehousing activities, as one of the basic functions of the warehouse that is because the distribution is not a general sense of the transport, but is a natural extension of the warehouse, warehouse and distribution center for the development of memory requirements, if there is no distribution, warehouse It is still an isolated storage warehouse; as for information processing, is a common phenomenon in modern economic activities, of course, should also be one of the warehousing activities, from information processing, will not become the modern warehouse.

- Q: What is lean storage?

- With the development of enterprises, enterprises need to increase investment in all aspects, especially in warehousing, but also in warehousing, storage facilities, handling equipment, sorting equipment, barcode technology and other aspects of investment.Application of bar code technology can effectively solve the enterprise operation efficiency is low, the inventory control is difficult, difficult to manage their problems, and can easily cope with the market change constantly.Implementation of warehouse management informationization, we must establish the only encoding for each and every variety of products, and the use of bar code printer to make barcode label on the packaging of clothing or hang in the product tag.This will not happen again, the goods can not be found, missed the opportunity to sell the situation.

- Q: What brands of operating equipment are used in the major logistics and express companies in China?

- Many express companies are designed for special companies. They include roller conveyors, electronic packages, sewing racks, sewing machines, wireless guns, trays and the like

- Q: The disadvantages of traditional warehousing and the advantages of modern warehousing

- Chinese traditional warehousing industry is the product of the planned economy, then they are mainly to provide warehousing and a small amount of short distance transport services for the industry's material or commercial enterprise, which is engaged in the traditional logistics business, the low level of information technology, the extensive mode of operation, the economic benefit is not good.

- Q: What shelves are there in the logistics equipment?

- Logistics equipment has been applied in every link of logistics. At present, both in the production, warehousing, circulation process of transportation and distribution, logistics center packaging processing, handling, loading and unloading, logistics equipment has been a certain application.Specialized new logistics equipment and new technology, logistics equipment constantly emerging. With the continuous refinement of the logistics sector, with the increasing demand for logistics services to meet customer needs, the new logistics equipment and new technology, logistics equipment continue to emerge. Most of these equipments are specialized in logistics operation of a logistics link, a specialized commodity, a specialized customer's equipment, and its specialization is very high.

Send your message to us

Light Duty Pallet Racking System for Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords