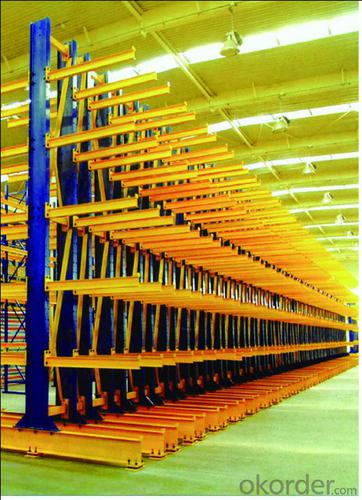

Cantilever Type Racking System for Warehouses

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

4S pallet racking system has simple structure of upright and beam and reliable strucuture.

It's used for 4S store.

Goods for storage and carrying has no limits. It's usually used in pallet storage and forklift warehouse.

The beam and upright profiles are well produced by roll forming techonogy and fine steel is used for the manufacture.

It consists of upright, beam, strut.It forms structure by C upright and weld beam. It has 75mm adjustment range.

The system can be customized designed to the warehouse condition.

Feature:

· Large loading

· Customized design

· Professinal

Images:

Specification:

Loading weight | 4000KG/layer |

Height | customized |

FAQ:

What is note for purchase?

Pallet size,good weight, warehouse sapce and height, forklift details, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation.

- Q: What are the basic principles of warehousing?

- The "warehouse" also known as the warehouse, store items for buildings and facilities, for housing construction, large containers, caves or specific sites, is to store and protect the function of items; "reservoir" said storage for use, storage, storage, delivery and use of means, when applied to tangible items also for storage. "Warehousing" is the act of using a warehouse to store and store items that are not immediately available. In short, warehousing is the act of storing goods in a particular place.

- Q: What are the logistics and warehousing equipment? The more, the better

- Plastic tray tray, wooden pallets, steel pallets, storage cage, tchouk frame, logistics trolley, forklift cage, shelves of light, medium, heavy.

- Q: What are the types of logistics equipment?

- According to the equipment in the logistics activities in a considerable position, can be divided into fixed equipment and movable equipment. Fixed equipment such as railway, highway, bridge and tunnel; stations, ports, warehouses and other buildings I equipment such as train, cars, ships, mobile handling equipment.

- Q: What are the advantages of automated warehousing and its role in logistics systems?

- The utilization rate of logistics resources is low. On the one hand, because the traditional warehouse space caused by the large number of resources in the storage of headroom tend not to use idle waste; on the other hand, because the traditional warehouse management and operation model are used in the original mode of operation, the ability of warehouse equipment did not fully play out, to a certain extent, also caused the waste.

- Q: What are the commonly used automation equipment in warehouse logistics?

- Such as the commonly used transport equipment, the car these

- Q: What does the storage equipment mainly consist of?

- Warehousing equipment mainly consists of:1, a variety of specialized warehouses;2. Facilities in the warehouse;3, all kinds of ancillary equipment, such as: explosion protection, fire fighting, metering, temperature measurement, ventilation, information management, etc..

- Q: What is the warehousing logistics distribution center?

- The distribution center must first purchase the goods to be supplied and distributed in order to supply materials to its users, that is, manufacturing enterprises or commercial enterprises, in a timely and accurate manner. The distribution center shall formulate and adjust the unified and comprehensive purchasing plan according to the change of supply and demand in the market, and shall be organized and implemented by special personnel and departments.

- Q: What role does warehousing play in logistics?

- Warehousing conditions are specific tangible or intangible places with modern technology. "Specific", because each enterprise's supply chain is given, the place is of course specific storage; of course refers to tangible places of warehouse, yard or tank, under the background of modern economic, storage can also be carried out in the virtual space, also need a lot of modern technical support, leaving the modern warehouse facility equipment and information technology, there is no modern warehousing.

- Q: The difference between electricity supplier logistics and traditional logistics warehousing management

- (1) the traditional logistics is the storage area and the sorting area sharing, its essence is the few varieties, the massive quantity enters and sells pattern to decide. The facilities in the library are usually flat warehouse (stacking) and stereoscopic high shelf. Because of the characteristics of large quantities, the number of boxes to go in and out, and even to support as auxiliary units; storage and transfer of more pallets as the carrier.(2) logistics providers due to the characteristics of multi variety and small batch, at present by manual, it is necessary to use special storage area to improve storage utilization; improve the picking efficiency picking area (with special light shelf, a flat tray storage supplement. )

- Q: What are logistics facilities and equipment?

- Logistics facilities and equipment include logistics, machinery, equipment and logistics infrastructure.

Send your message to us

Cantilever Type Racking System for Warehouses

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords