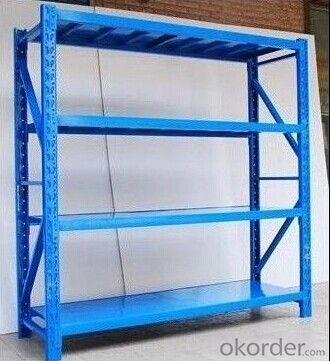

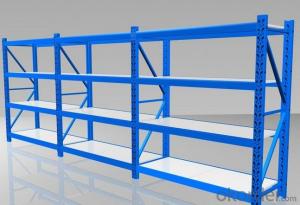

Light Duty Type Racking System for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Light duty type pallet racking system has simple structure of upright and beam and reliable strucuture.

It's used for light loading weight goods storage.

Goods for storage and carrying has no limits. It's usually used in pallet storage and forklift warehouse.

The beam and upright profiles are well produced by roll forming techonogy and fine steel is used for the manufacture.

It consists of upright, beam, strut.It forms structure by C upright and weld beam. It has 75mm adjustment range.

The system can be customized designed to the warehouse condition.

Feature:

· Large loading capacity

· Customized designing

· Professinal

Images:

Specification:

Loading weight | 1000KG/layer |

Height | customized designed |

FAQ:

What is note for purchase?

Pallet size,good weight, warehouse sapce and height, forklift details, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Installation is provided for users. We send engineers to users's spot to carry out installation.

- Q: What are the logistics and warehousing equipment? The more, the better

- Mezzanine shelves, cantilever shelves, through shelves, hydraulic cars, forklifts and so on

- Q: Logistics warehousing problems?

- The term "logistics" (LOGISTICS) refers to the general circulation process of production, distribution, retail, supply, transportation, warehousing and so on. It means "logistics", which is developed for the effective use of military organization in order to achieve a rapid logistics support front-line use support system in the transport of weapons, ammunition and food such as Europe and the United States, was later applied to commercial institutions, along with the rapid development of world economy and trade, logistics service architecture, quickly from the early stage, growth is one of the most economical and reasonable service system in transportation industry. Along with the modern network information technology is increasingly improved and the free circulation of goods, logistics (transport, storage, handling, packaging, distribution processing) information management, will be a key factor in international competitiveness of enterprises.

- Q: What are the characteristics of electric power supplies (such as transformers, cables, etc.), mainly in logistics, warehousing and transportation?

- High voltage class power equipment is generally divided into parts, low voltage class power equipment is generally integral transportation.

- Q: What are the categories of logistics?

- Social logistics belongs to the macro scope, including equipment manufacturing, transportation, warehousing, distribution, packaging decoration, information services, public logistics and third party logistics through the logistics enterprises; the micro logistics category, including production logistics, supply logistics, sales logistics and recycling logistics and waste material logistics etc..

- Q: What does the storage equipment mainly consist of?

- Warehousing equipment mainly consists of:1, a variety of specialized warehouses;2. Facilities in the warehouse;3, all kinds of ancillary equipment, such as: explosion protection, fire fighting, metering, temperature measurement, ventilation, information management, etc..

- Q: What role does warehousing play in logistics?

- Warehousing methods and levels are reflected in effective planning, implementation and control. Planning, implementation and control are the basic connotations of modern management. Scientific, reasonable and precise storage can not be achieved without effective planning, implementation and control.

- Q: The advantages and disadvantages of logistics line type I U type L

- I logistics center has a separate entry and exit goods, which are distributed in the logistics center on both sides, straight to the point (Figure 1). Due to the I logistics center operation flow is linear, the operation of parallel lines, so whether people or logistics, collision mutually cross points is relatively minimal, can reduce the possibility of operators and logistics handling car collision.The biggest problem existing in I logistics center is the entry and exit goods Taiwan far apart, the overall increase in cargo transportation routes, reducing efficiency, but the linear process is relatively simple, relatively easy to adapt to the operator, can make up for deficiencies in this area. In addition, as the exit and arrival platform is located on both sides of the logistics center, at least two teams of security teams are responsible for the supervision of the two goods stations, increasing personnel input and operating costs.

- Q: What aspects of logistics and warehousing management?

- Should meet the following requirements in the general layout of warehouse: (1) abide by the laws and regulations of various buildings and facilities planning; (2) to meet the requirements of warehouse operation smoothly, avoid repeated handling circuitous transportation; (3) ensure the storage of goods safety; (4) ensure the working safety; (5) the maximum use the warehouse area; (6) to make full use of warehouse facilities and equipment; (7) comply with the security and fire protection requirements; (8) consider warehouse expansion requirements.

- Q: What are the third party logistics? What are the advantages and disadvantages?

- 3PL can meet these requirements in a fast and cost effective way that is often difficult to achieve by manufacturers alone. Similarly, 3PL also has the ability to meet the potential customer needs of manufacturing firms, thereby contributing to the communication between producers and retailers.

- Q: What are logistics facilities and equipment?

- Logistics facilities and equipment include logistics, machinery, equipment and logistics infrastructure.

Send your message to us

Light Duty Type Racking System for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords