Large Diameter HDPE Water Supply and Gas Supply Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery:

| Packaging Detail: | Export packing, covered with film for dustproof, wooden crates packing for sea transport |

| Delivery Detail: | 50 days after receiving 30% advanced payment |

Water Supply And Gas Supply HDPE Large Diameter Pipe Production Line

Welcome to visit our Water Supply And Gas Supply HDPE Large Diameter Pipe Production Line!

Application:With this production line you can extrude high quality large diameter water supply and gas supply pipes.

The pipes produced by our line have excellent stiffness and flexibility, resistance to creep deformation,excellent heat-linkage. Large diameter HDPE pipes start to play very important role in the city water and gas supply systems.

Properties and Advantages: The production line consists of control system, extruder,mould, calibration unit, haul-off unit,planetary cutter and stacker.

Downstream equipment:This line is assembled lattice or spiral mould,new type calibration unit and spraying cooling bath. Advanced PLC control system and large chromatic liquid-crystal screen make the operation more convenient, having a friendly human-machine interface.

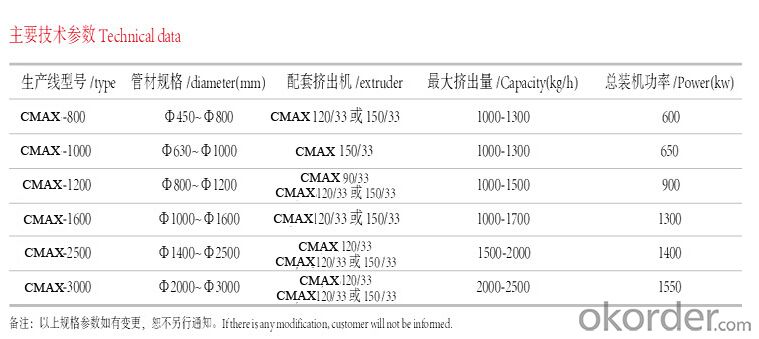

Main Technical Parameters:

Our company can design and manufacture products with different specs for clienteles.

The features:

1, We have set up one special forging team to design –develop-produce-distribute-debug-repair for our clienteles.

2, We possess strong technical power, high-tech, one complete set of checkout equipment, abundant debugging experience and timely after-sale service.

3, The most crucial is that we brave enough to innovate, keep enterprise, keep improving.

If you are interested in our product, please be free to contact us. Whether we could cooperate, we would do our best to help you. I’m confident that will be benefit to you and us!

1. The Extruder:

2.The Die Head:

3.The Vacuum Sizing Water Tank:

4.The Spraying Cooling Water Tank:

5.The Caterpillar Tractor:

6.The Cutter:

7.The Stacker:

8. The HDPE Pipe:

- Q: Basic parameters of extruder screw

- 1, screw diameter Ds screw diameter is the diameter of the thread, the extruder production capacity (extrusion amount) is approximately proportional to the square of the diameter of the screw and, under the same other conditions, the screw diameter increases a little, significant increase will cause extrusion amount, the effect was even greater than the effect of the increase of screw speed on the extrusion rate is high. Therefore, the screw diameter is used to characterize the specifications of the extruder.

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: What is the adjustment method of China's extrusion machine die?

- (5) sense of mold: it is the method of experience versus mold. Feel the thickness of the plastic layer by hand and adjust the mold. The utility model is suitable for the outer protective layer of large cross section wire and cable.

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q: What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q: The working principle of an extruder

- The material is moved forward by the extrusion of the screw and the barrel, and the material is fully homogeneous and plasticized in the process of material advance. Then the material is extruded by a certain shape of the die by the die of the die.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- 1, extrusion methodAccording to plasticizing methods: dry extrusion and wet extrusionPress the way: continuous extrusion and intermittent extrusion2, characteristicsContinuous production, high efficiency, simple operation, wide range of applications [Edit] paragraph extrusion molding equipment 1, the hostExtrusion system: composed of screw and barrel, it is the key part of extruder. Its function is to melt plastics, quantitative, constant pressure, constant temperature extrusion of meltDrive system: drive the screw to increase the required torque and torqueHeating and cooling system: guarantee the temperature of plastic and extrusion system in molding process2 auxiliariesIt is composed of head, setting device, cooling device, traction device, coiling device and cutting3 、 control systemIt consists of electric apparatus, instrument and actuating mechanismPurpose: to control the main and auxiliary motor, in order to meet the demands of speed and power; control main engine temperature and pressure and flow, to ensure product quality; to achieve automatic control of the extrusion unit, ensure the coordinated operation of main and auxiliary equipment. [edit this paragraph] extruder extruder overview of plastic extruder is the host, it consists of extrusion system, transmission system and the heating and cooling system.

Send your message to us

Large Diameter HDPE Water Supply and Gas Supply Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords