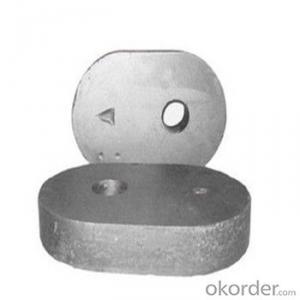

Raw Materials for Refractory Ladle Nozzle Pocket Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ladle nozzle Pocket Bricks

According to the forming method, ladle nozzle Pocket Brick can be divided into two categories, molding and vibration casted.

The products adopt a unique recipe and production process, with excellent properties of stable structure, anti-erosion, corrosion resistance, good thermal shock resistance and long service life.

Concrete material: high alumina corundum, chromium-corundum, magnesium –carbonaceous, which able to meet the production needs of various kinds of steel.

- Q: hat kind of fire retardant materials are there

- There are many flame retardant plastics, which are modified on the basis of raw materials, such as flame-resistant ABS, flame-resistant HIPS, flame-resistant PP, flame-resistant PE, flame-resistant the PET, flame-resistant PBT, flame-resistant PC, flame-resistant PC/ABS alloy. Now there are mainly halogen flame retardant, though there are a lot of researches about halogen free flame retardant, the product stability and flame retardant effect remain to be improved. Testing methods of flame retardant materials are mainly: horizontal and vertical combustion, oxygen index method, NBS smoke box , thermal analysis, cone calorimeter, etc.

- Q: What is the importance of silicon powder in refractory processing?

- it can certainly improve the fire resistance

- Q: What are the materials for refractory materials? What are their names?

- High temperature oxide materials in refractory special applications, such as aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, including metal ceramics, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: For refractory knowledge. What is the ratio of clay ramming?mass?

- Soil aggregates, dispersing agent, water reducing agent, plasticizer, binding agent and powder! ~ Bone meal feed approximately 6, OK

- Q: Where is refractory used? Thank you!

- Currently, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, ceramics and other industries. The current definition of refractory does not only depend on whether the refractoriness is above 1,580℃.

- Q: What is the material composition of the new fire-resistant coating?

- The basic composition of thick coating steel structure fire is: Binder (Portland cement, magnesium oxychloride or inorganic high-temperature bonding agent), aggregate (expanded vermiculite, perlite, aluminum silicate fiber, mineral wool, rock wool, etc.), chemical additives (modifiers , hardening agent, waterproofing agent) and water. Fireproof coating binders Portland cement, magnesium oxychloride cement and an inorganic binder of the fire-resistant coating for steel structure base material. The conventional inorganic binder include alkali metal silicates and phosphates substances.

- Q: Which brand of AAA refractory is good?

- Foshan Nanhai Yanbu Shuying fire-resistant insulation material is very good, and it is a professional company of the production and sale of refractories. Our company specializes in the production of refractory bricks, refractory bricks, refractory castable, refractory aggregate, refractory materials, bauxite, alumina bricks and to undertake the production of various common refractory bricks and non-sizing bricks. The Zhengzhou Fire High Temperature Materials Co., Ltd. is also a good company. It is a collection of R & D and production company. The company mainly produces refractories, refractory bricks, refractory castable, refractory aggregate, refractory materials, special refractory bricks.

- Q: Which kind of external wall fire barrier zone material is better?

- I recommended foam cement and particulate thermal insulation composite waterproof material, which is fire isolation area product, which uses surface of vertical?plate arranged fiber technology to make the compressive?strength in the vertical direction up to above 80KPa. At the same time, under the conditions of both exterior heat insulation and effects of humiture in the long-term, it can still maintain the non-aging performance of various aspects, and safety (reliability), fire resistance and excellent durability.

- Q: Can anyone say something about what A-level fire-proof decorative material is?

- The major products are material monomer A-level and composite A-level, now a lot of B-level material is wrapped in calcium silicate board. The foam cement overall composite is level A, such as phenolic aldehyde composite, as well as some of the foam paddings, monomer A-level includes rock wool, ultra-thin insulation panel and the like. But there are few products with real sound A level qualification. Many manufacturers are playing the edge ball with A-level fire rating examining reports and B-level system detection reports and records, but this situation will not last long, which will soon be clear.

- Q: What is the quote of fireproof and soundproof materials used in KTV?

- 1. fire retardant, sound absorbing sheet,eggs,pyramid,sound-absorbing material, piano room, studio, KTV, with glue on the rear, 15 Yuan 2. bar, KTV, fireproof sound insulation cotton, sound-absorbing materials, studio, eggs, drum practice room, sound-absorbing and sound insulation materials, pyramid, 25 Yuan 3. fireproof wood excelsior absorbent, sound absorbing board, wall ceiling decoration materials, materials, theater, KTV, wood color fiberboard, 30 Yuan.

Send your message to us

Raw Materials for Refractory Ladle Nozzle Pocket Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords