JS500 concrete mixer

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

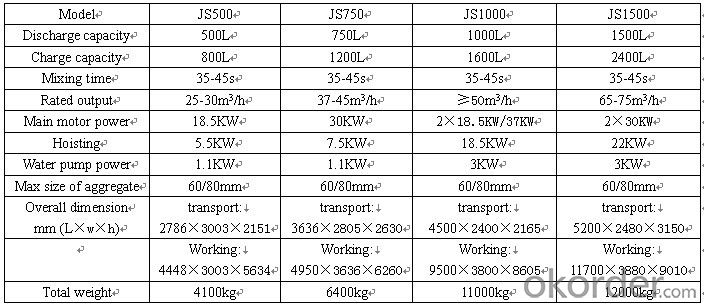

The model of the machine is JS series double-shaft compulsory mixer which have the advantages of reasonable structure, safe and reliable operation, low energy,excellent mixing performance, high efficiency and so on. It has the dual advantage of standalone using or as the supporting host of the concrete batching plant. This machine can composed with different kinds of PL series dosing machine of the concrete batching plant, or according to the customer requirements as the host of the large or medium-sized concrete batching plant, can mixing dry-hard, lightweight aggregate concrete and any other various kinds of mortar. It is suitable for all medium or large construction sites which is the ideal equipment of the hydropower, roads, ports, airports, bridge, medium or large concrete prefabrication plants and the manufacture of the commercial concrete. Now we have JS500, JS750, JS1000, JS1500, JS2000, JS3000 and any other type available.

- Q: What are the small concrete mixers

- The common type of small blender is JZC350, JZC500, JDY350, JDY500, JS500, JS750, JS1000. Concrete mixer, including through the shaft connected to the transmission mechanism of driving and driven by the actuator cylinder, the cylinder cylinder jacket around the cylinder cylinder gear ring set, set with the ring gear meshing gear on the shaft. The utility model has simple structure, reasonable, the use of mesh gear, gear ring, which can effectively overcome the fog had, between the roller and the mixer drum skid phenomenon; The driving mechanism can further assure the skidding between the roller and the mixer.

- Q: What are the pros and cons of a concrete mixer?

- Are you talking about the production line at the blender station or is it the usual blender or that? These I understand

- Q: How long will it take for a concrete mixer to beat ten square?

- The first set of 10 square is 120, and the first set of 2 squares is calculated from the above, and the time is saved by 4 minutes in 4 minutes, the average of 15 minutes is calculated by C50 high performance concrete. If it's a C20 no water reducer, just five minutes!

- Q: Concrete mixers need to be aware of which things

- The concrete mixer should be set in a flat position, and the wheel shaft will be placed on the back and back of the square, so that the tyre should be set up so that it will not move during the run. 2, the concrete mixer should be protected by secondary leakage, and after the power connection is put on before work, it must be carefully checked, and it will be used only if it is considered qualified by the empty car test. Commissioning should check when mixing drum speed whether appropriate, under normal circumstances, the proportion of empty car speed car was faster (after loading) 2 ~ 3, such as the difference is more, should adjust pulley and the proportion of the driving wheel. The rotating direction of the mixing cylinder shall be in accordance with the direction of the direction of the arrow, if it is not true, the motor connection shall be corrected. 4, check whether the transmission clutch and brake is flexible and reliable, wire rope is damaged, track pulley are in good condition, surrounded by accessibility and lubrication situation of each part. After turning on the machine, it is often noted that the parts of the concrete mixer are working properly. When stop, check whether the concrete mixer blade is bent and the screw is loose or not. 6, when the completion of concrete mixing or pause is expected to more than 1 h, besides excess stock out of the net, the application of stones and water to pour into shaking inside the cylinder, turn on, put the glue on the cylinder of the mortar all discharged after rinse. No water is allowed in the cylinder in case the cylinder and blade are rusted. It should also clean up the outside of the mixing cylinder to keep the machine clean. 7, after work and stop after work, should pull off power without power, and lock switch box, to assure safety.

- Q: What is the difference between a concrete mixer and a mortar mixer

- Concrete is made by mixing several kinds of aggregates and water, cement and mixing. Because of containing coarse aggregate, and therefore require huge stirring power, also requires wear-resisting, so his stirring blades and liner is high chromium cast iron, or pieces, power is big, like JS500 will be 18.5 kw motor to drive! And the mortar is not contain coarse aggregate, so the power is very small, the power consumption is very low, do not need wear-resisting piece, appear easy and clever!

- Q: How is the concrete mixer cleaned

- I don't know which type of blender you're talking about. The self-falling mixer is the roller mixer. Rinse directly with water. The strong mode is also the JS mixer water rinse to notice whether the shaft end of the shaft is clean, and be careful not to use the side shovel to break down otherwise there will be a sealing problem

- Q: How much is the blender machine stirring

- The JZC350 concrete mixer is a two-cone-shaped machine that inverts the flow mixer, which can be mixed with the plastic and semi-dry concrete of 60 mm. Stirring when the mixer is turning, and automatically when reversing. Each pot can be mixed with concrete 0.35 cubic meters. Native novel structure, advanced performance, high productivity, mixing of good quality, compact structure, low energy consumption, the advantages of convenient operation, applicable to the general construction sites, road, bridge engineering and small concrete precast construction situations such as a file. The output capacity is 350 litres The incoming capacity is 560 liters 4, productivity 10 ~ 14 m 3 / h The work cycle is 30 to 40 times per hour 6, form a complete set of power

- Q: The safe distance of the concrete mixer

- The single machine switch box is in the concrete mixer. That distribution box is the switch box. If it's a complete set of stations, it's in the control system, which is where the computer operates. This distance is set by itself

- Q: For example, what is the more detailed and better td-50 td-80 td-60

- Concrete mixer points generally mixer and forced mixer, currently used in engineering is forced, the difference is that the former is the shell in turn, the latter is in inside agitation. The most commonly used parts of a strong mixer are: hoisting bucket wheel, mixing arm, blade, hopper limiter, liner. Normally the mixing arm, blade, and lining plate for the vulnerable parts, should be replaced in time during construction.

- Q: The difference between concrete mixer and concrete mixer

- Concrete mixing plant is including weighing, feeding and a series of complete system of equipment, and concrete mixer is a mechanical stirring mixer belongs to a kind of mixing equipment. The mixing machine in the mixing station is a strong mixer in the concrete mixer, so it is fair to say that the mixer is a member of the whole equipment of the mixing station. No matter which of the two devices during start-up operation, safe operation, must pay attention to the hopper should ensure reliable braking at any position, hopper should not fall; The movement of the upper and lower limit devices should be sensitive and reliable. The safety cover of the open gear and belt should be complete and intact, and the safety pins and safety pins of the hopper safety hook and track should be in good condition and complete. The leakage protector parameter should match, the installation should be correct, the action should be sensitive and reliable. Belong to the mixing machine, concrete mixer and concrete mixing station their application field the same, only choose the appropriate mixing plant equipment according to user's demand

Send your message to us

JS500 concrete mixer

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords