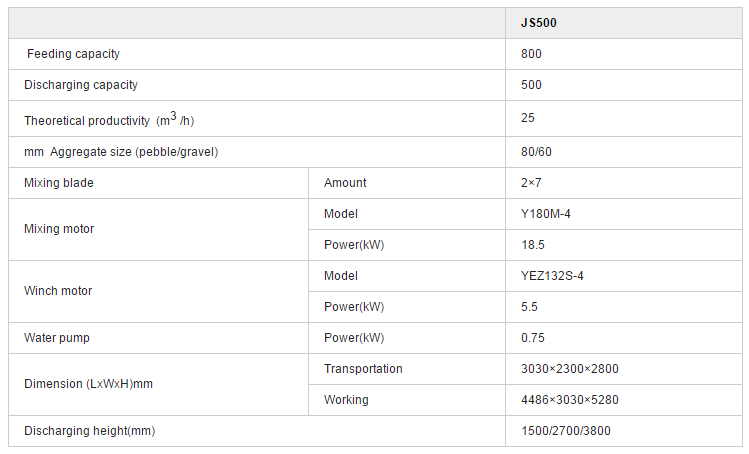

Concrete mixer JS500 / CE & ISO Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

Yuanyou JS series concrete mixer is double horizontal spindle forced mixer. It can work alone, or be combined with Yuanyou PL series batching plant to work as simplified concrete mixing plant, or work as the main machine of the mixing plant. It can be utilized in large, medium-sized, and small precast concrete plant and projects like roads, bridges, water conservancy, ports, and industrial or civil constructions. It can be used to mix dry concrete, plastic concrete, fluid concrete, lightweight aggregate concrete and various mortars. It is a highly efficient machine with extensive applications.

Yuanyou concrete mixer features:

1. Large diameter drum prolongs the service life of the steel wire rope;

2. Wear-resistant alloy casting plate and blade can prolong the replacement interval of the wearing parts;

3. 100% full load test ensures reliable operation.

- Q: What are the small concrete mixers

- The common type of small blender is JZC350, JZC500, JDY350, JDY500, JS500, JS750, JS1000. Concrete mixer, including through the shaft connected to the transmission mechanism of driving and driven by the actuator cylinder, the cylinder cylinder jacket around the cylinder cylinder gear ring set, set with the ring gear meshing gear on the shaft. The utility model has simple structure, reasonable, the use of mesh gear, gear ring, which can effectively overcome the fog had, between the roller and the mixer drum skid phenomenon; The driving mechanism can further assure the skidding between the roller and the mixer.

- Q: A concrete mixer can last for years

- Both, so you need an old driver and your partner in situations you don't know very well. 2, in the car use out of the maintenance in time according to the requirements of specification and manufacturer, at ordinary times into the construction site to site operators replacement using method, avoid ruining their error was to take. 3, service phone to keep in mind that other manufacturer, encounter problems consult factory staff more at ordinary times, during the warranty period (6 months) don't oneself to repair vehicles, service personnel to solve the problems to make manufacturer, to avoid unnecessary dispute in the future. Special attention is to keep the inside and outside of the tank, prevent the appearance of the can and keep clean, and can sell the car for a good price in the future.

- Q: How many tiles are in the concrete mixer on the site

- The power of the mixer motor on the site is 75KW

- Q: How many cubic meters of concrete is mixed with concrete mixer?

- The number of machines varies from one to the other. Look at the machine model.

- Q: How much is the blender machine stirring

- The discharge capacity 350 l 500 l Feeding capacity 560 l 800 l productivity 18-21 m3 / h 25 to 30 m3 / h Maximum size of bone grain (pebble/gravel) 60/40 mm 80/60 mm Stirring shaft speed 28 r/min 24 r/min The engine power 19.55 kw 24.75 kw Mixing time 30 s 30 s Overall dimensions 2530 * 2340 * 2340 mm 2600 * 2790 * 2790 mm The weight 3700 kg 4000 kg Related instructions Product specifications: JZC350 Product price: 10000

- Q: How much concrete the concrete mixer can stir at a time

- 350-concrete mixer is a double conical turning out of the feed mixer, and the plastic and semi-dry hard concrete of 60 mm. Stirring when the mixer is turning, and automatically when reversing. Each can be mixed with concrete 0.35 cubic meters. Depending on the size of the concrete, the amount of cement used varies.

- Q: What is the JZ250 concrete mixer

- The characteristics of the JZC concrete mixer JZC type mixer is according to gb/t9142-2000 < < concrete mixer technology condition > > the design and manufacture, reasonable structure, and has high productivity, mixing of good quality and aesthetically pleasing, convenient movement, is a kind of more advanced models.

- Q: 250 litres of the blender once made concrete

- 250-litre agitator is measured at a time of 0.25 m3, which is about 80% of the amount in real time, avoiding mixing and mixing

- Q: The difference between concrete mixer and concrete mixer

- Concrete mixing plant is including weighing, feeding and a series of complete system of equipment, and concrete mixer is a mechanical stirring mixer belongs to a kind of mixing equipment. The mixing machine in the mixing station is a strong mixer in the concrete mixer, so it is fair to say that the mixer is a member of the whole equipment of the mixing station. No matter which of the two devices during start-up operation, safe operation, must pay attention to the hopper should ensure reliable braking at any position, hopper should not fall; The movement of the upper and lower limit devices should be sensitive and reliable. The safety cover of the open gear and belt should be complete and intact, and the safety pins and safety pins of the hopper safety hook and track should be in good condition and complete. The leakage protector parameter should match, the installation should be correct, the action should be sensitive and reliable. Belong to the mixing machine, concrete mixer and concrete mixing station their application field the same, only choose the appropriate mixing plant equipment according to user's demand

- Q: What is the difference between a concrete mixer, a JL type and a JW type?

- The jw-200 type mixer consists mainly of the main parts, such as the platform car, the motor, the gearbox, the feeding mechanism, the mixing mechanism and the feeding trough. After the electric start-up, the process of feeding, stirring and discharging is carried out through the transmission such as the triangle belt, the coupler and the worm gear reducer. The concrete mixer is small and suitable for underground.

Send your message to us

Concrete mixer JS500 / CE & ISO Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords