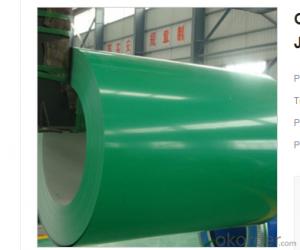

JIS VERY BEATIFUL PREPAINTED GALVANIZED STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

JIS BEATIFUL Prepainted galvanized steel coil ,with Gi as base metal after pretreatment ( degrease and chemical treatment) and liquid dope with several layers of color then after firing and cooling finally the plate steel is called Pre-painted galvanized steel is good capable of decoration ,molding corrosion resistance

Product Features

Excellent process capability

Smooth and flat surface

Workability durability

Excellent heat resistance performance

High Strength

Good formability

Good visual effect

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

2. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: I have heard using the BRASS casing is the best thing for an AR-15? Should i just use Brass or Steel?

- Two reasonable answers here. But let me say this...I just don't like the idea of steel touching steel at a high rate of speed (like when it's being cycled in and out of the chamber of a rifle). I can't help but feel that some sort of erosion is going to occur to the chamber of the rifle - which obviously isn't a good thing. If it were me, I would stick with firing brass casings only. The only gun I would fire steel casings through would be a cheaper SKS

- Q: Are steel coils used in furniture manufacturing?

- Yes, steel coils are commonly used in furniture manufacturing for various purposes such as providing support and stability to seating structures, enhancing durability, and ensuring proper weight distribution.

- Q: How much do steel coils weigh?

- The weight of steel coils is subject to variation, which is determined by multiple factors including coil thickness, width, length, and the particular type of steel employed. In general, steel coils can range in weight from a few hundred pounds to several tons. It should be emphasized that the measurement of steel coils typically revolves around their weight per unit area, referred to as the "basis weight" or "coil weight".

- Q: Steel is a mixture of Iron Carbon . So , is steel a metal or non - metal ?

- Steel is an alloy mostly made of metallic elements. You really wouldn't classify steel as a metal or a nonmetal. That terminology is mostly used with pure elements.

- Q: And by how much? I'm pretty sure that sterling silver is stronger, but I'm wondering if I could still use a metal stamp to stamp into something that's stainless steel - if it would be soft enough?

- No way steel is by far stronger. Tensile strength of Sterling silver 207 MPa Tensile strength of Stainless Steel 515 MPa

- Q: Does anyone know if there is any info on Steel Manufacturing techniques, utilyzing electro/mechanical methods in order to create carbon nanotubes from the %C already inherant in the steel. In other words just modifying the Geometry of the Carbon the already makes up some of the steel.

- I don't think that would work. First off, there's not enough carbon in steel - even very high carbon steels are only about 2% carbon. Second, the iron atoms in steel form a crystal lattice, in the shape of a cube, with another iron atom in the middle of the cube. Each cube is about 0.3 nm per side. Carbon atoms work their way into the crystals and displace the iron atoms. But a carbon nanotube is around 1 nanometer in diameter - that's 3 times as big as the iron lattice! So a nanotube wouldn't fit. One thing you might do, however, is make a composite - mix the materials together on a scale a little bigger than the atomic scale that the iron and carbon mix to make steel. Just like a carbon fiber bicycle frame or ski pole is strands of carbon (much bigger and not as strong as nanotubes) held together with epoxy, you could hold nanotube strands together with metal. Not sure it would be good for armor, but if you can figure out a way to do it, I'm sure someone will come up with a use for it!

- Q: What is the lifespan of a steel coil?

- The lifespan of a steel coil can vary depending on various factors such as the quality of the steel, its usage and maintenance. However, on average, a well-maintained steel coil can last anywhere from 10 to 30 years.

- Q: How are steel coils used in the production of fireproof doors?

- Steel coils are used in the production of fireproof doors as they provide the necessary strength and durability to withstand high temperatures and prevent the spread of fire. The coils are formed into sheets or plates, which are then used to construct the framework and core of the fireproof doors. This ensures that the doors can effectively resist fire and protect buildings and occupants from its dangers.

- Q: I'm getting my nose pierced, meaning that i have to keep the piercing in for a prolonged time. i've always had reactions when wearing sterling silver or fake earrings (i dont know what types of metal they were) after wearing it overnight. Will I get a reaction on my nose piercing if the stud is surgical steel?

- The chances of a reaction from the stud is minimal. Surgical steel is an alloy specifically designed to make sterile safe surgical equipment. Often made with titanium or nickel, surgical steel is highly reactive and forms an oxidized layer when made. This layer creates a stable surface. The titanium and nickel are both very hard and resistant to scratches which make for easy sterilization. This will help keep your piercing clean. Be sure to follow the directions you receive when you get your piercing and keep it clean.

- Q: if someone wanted to melt cast steel or iron into small-relatively simple shapes such as rod-tapered rod-or etc... how would you go about melting the steel/iron what would the mold need to be made of?

- Sand casting useing silica sand was the classical method. Wood models called patterns made the cavity into which the metal was poured. Furnaces capable of melting iron and steel are not found everywhere. They are industrial machinery, not to be improvised. Some-one had better be very careful if he does get access to molten steel. There are some aspects of the process that are not intuitively obvious that can 'bite you' badly. Get at least some briefing from an experienced foundryman.

Send your message to us

JIS VERY BEATIFUL PREPAINTED GALVANIZED STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords